-

单晶金刚石具备多项优越的物理、化学特性。硬度高、导热性能好,具有从紫外到红外的宽波段光透过性、较高的击穿场强和禁带宽度,其还具有极高的载流子迁移率等性能[1-4]。目前,采用高温高压(HPHT)法和化学气相沉积(CVD)法生长单晶金刚石的技术已经取得了突破性的进步[5-6],而微波等离子体化学气相沉积(MPCVD)法则被认为在高质量、大尺寸金刚石稳定生长方面具备优势,围绕其沉积速率和沉积质量的研究已经有大量报道,然而,单晶金刚石关于电子器件的创新应用方面也极具研究价值。单晶金刚石在高功率器件[7]、量子信息处理及通信领域具有理想的应用前景[8-10],金刚石辐射探测器已经应用于核聚变、核工程、高能物理和医学物理等领域[11-13]。而要实现单晶金刚石在电子器件领域的应用,需要对其进行有效掺杂。而氮掺杂是研究最广泛的,CVD生长单晶金刚石过程中氮掺杂会形成氮空位色心(NV),而负氮位(NV−)的存在使其在量子计算、高分辨率探测器等方面的应用成为可能[14],但对金刚石中氮杂质的含量和存在形式皆有一定的要求,MPCVD生长单晶金刚石过程中采用delta掺杂对氮杂质浓度进行控制是具有一定优势的[15]。中高气压下单晶金刚石生长速率一般为10~30 µm/h,本实验室研究人员通过降低甲烷浓度将单晶金刚石预生长速率降至3 µm/h,以便对氮杂质生长层厚度及氮杂质浓度分布进行控制,而delta掺杂要求掺杂层为几纳米,但在掺杂生长过程中,运行于中高气压(1-20 kPa)下的常规MPCVD工艺由于生长速率过快难以对生长气氛进行控制从而难以满足在纳米层级上对氮杂质进行有效的delta掺杂[16],因此,可以通过降低工作气压来寻求单晶金刚石低速率稳定生长。电子回旋共振微波等离子体化学气相沉积(ECR-MPCVD)工作气压比常规MPCVD低3到4个数量级且能保持相对高密度的大面积等离子体(约1.0×1011 cm−3)[17],探究其在低气压条件下低速率同质外延生长单晶金刚石是非常有意义的。

本文借助高速光纤光谱仪在自主设计的ECR-MPCVD设备上对ECR微波等离子体进行诊断,发射光谱图中,基团浓度可以由谱峰强度所指代,基团浓度的变化也可以由谱峰强度变化所反映[18]。并借助铠装加热丝辅助加热,解决了ECR微波等离子体功率密度低而自加热不能满足单晶金刚石生长温度的问题,研究了ECR微波等离子体单晶金刚石同质外延生长工艺。

-

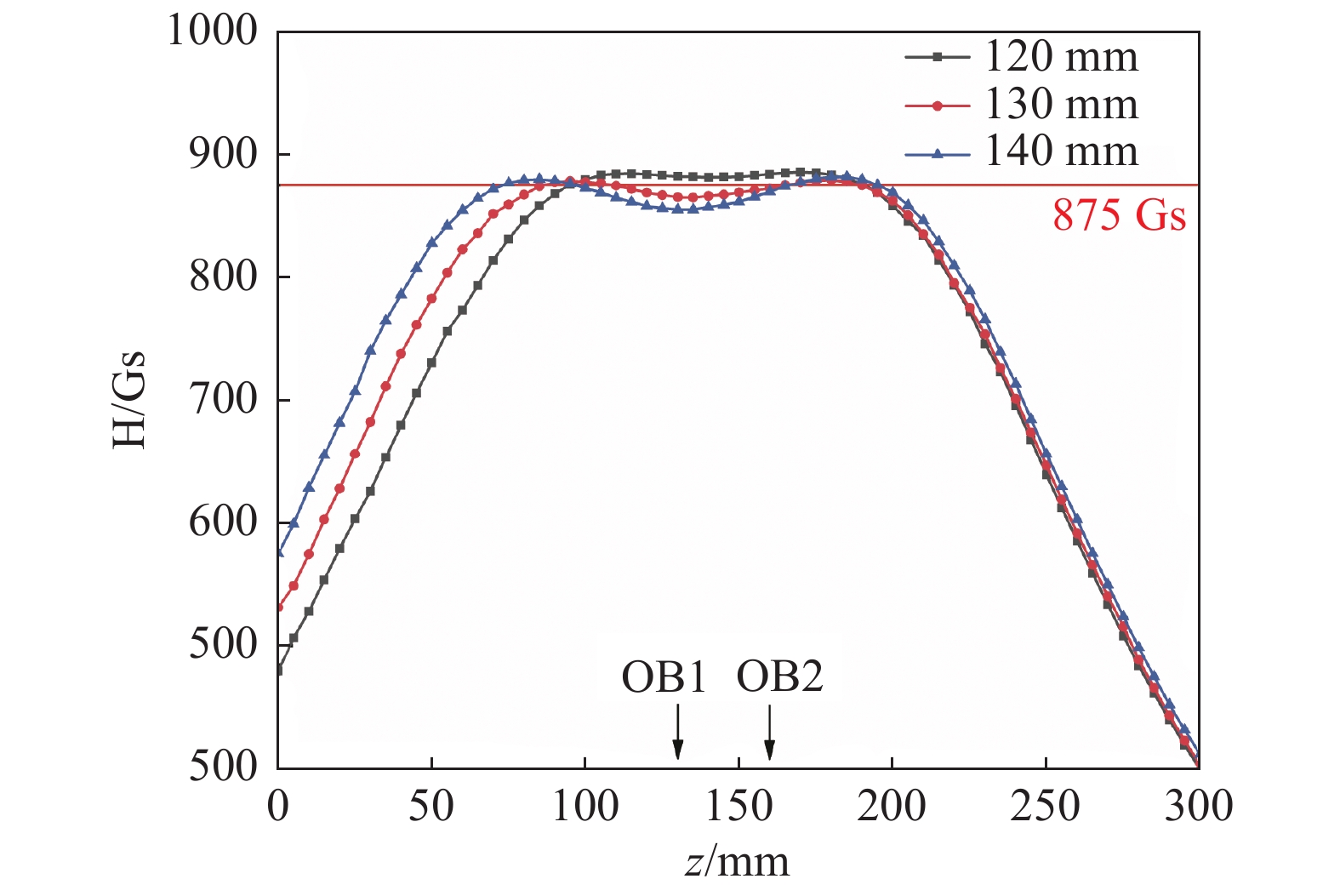

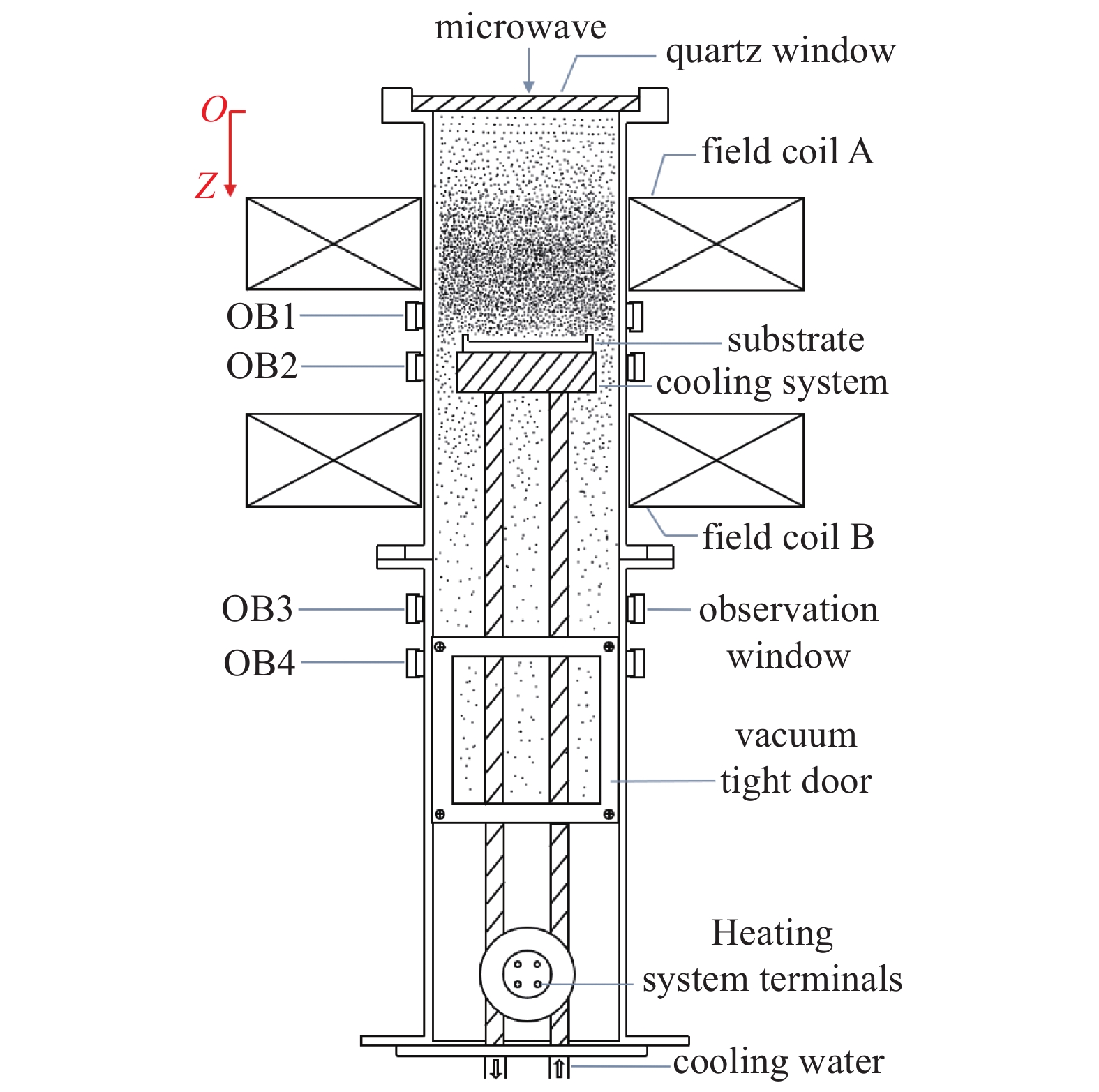

本实验使用自主设计并调试的ECR-MPCVD装置研究单晶金刚石的低速率同质外延生长,该装置主要由微波系统、磁场系统、真空系统和加热系统组成,沉积腔室和磁场线圈位置如图1所示,便于样品台及线圈位置的调节,设石英窗口处为z坐标轴零点,向下为z轴正向,腔室留有观察窗OB1(z=130 mm)、OB2(z=155 mm)、OB3(z=285 mm)、OB4(z=325 mm)以便于对ECR微波等离子体进行光谱诊断。由微波源产生的微波(2.45 GHz)在矩形波导中以TE10模式传输,由模式转换天线转换后经石英窗口耦合到圆波导中以TM01模式传输,通过三销钉阻抗调配器和模式转换天线调节优化其反射,微波功率在300~1200 W内可调。磁场系统由直流电源和轴向距离可调的AB两组相同线圈组成,通过调节线圈电流和线圈位置改变真空腔室内部磁场分布形态从而改变等离子体分布。真空系统由机械泵和涡轮分子泵、管道及阀门组成,可获得5.0×10−4 Pa的本底真空,进入真空腔室的气体流量由质量流量计控制。加热系统由平面螺旋形铠装加热丝、温控箱和水冷套组成,紧贴钼基片台且封装于水冷套中的加热丝所需电压由温控箱提供,加热丝表面温度最高能达到700℃且能保持恒温工作,水冷套隔绝加热丝与腔壁之间的热量传输且有支撑基片台的作用,基片台直径73 mm,位置可调。

-

将单晶金刚石种晶置于稀硝酸(25%)中并超声处理15 min,洗去机械抛光过程中残留于单晶金刚石抛光面的金属杂质;再分别用乙醇和去离子水多次交替超声清洗,每次5 min,直至单晶金刚石表面无明显杂质残留。再将单晶金刚石置于基片台上,考虑到等离子体对石英窗口的刻蚀作用,基片台位置在z为150~300 mm之间调节。调节线圈距离和线圈电流,控制两线圈之间最大磁场在875 Gs附近。微波功率1200 W,H2流量在20~50 mL/min范围内调节,CH4浓度在0.5%~8%范围内调节,工作气压控制在0.05~5 Pa之间。基片台位置和工作气压的不同,等离子体自加热温度不同,再通过温控箱控制所需辅助加热温度从而控制单晶金刚石种晶生长温度。

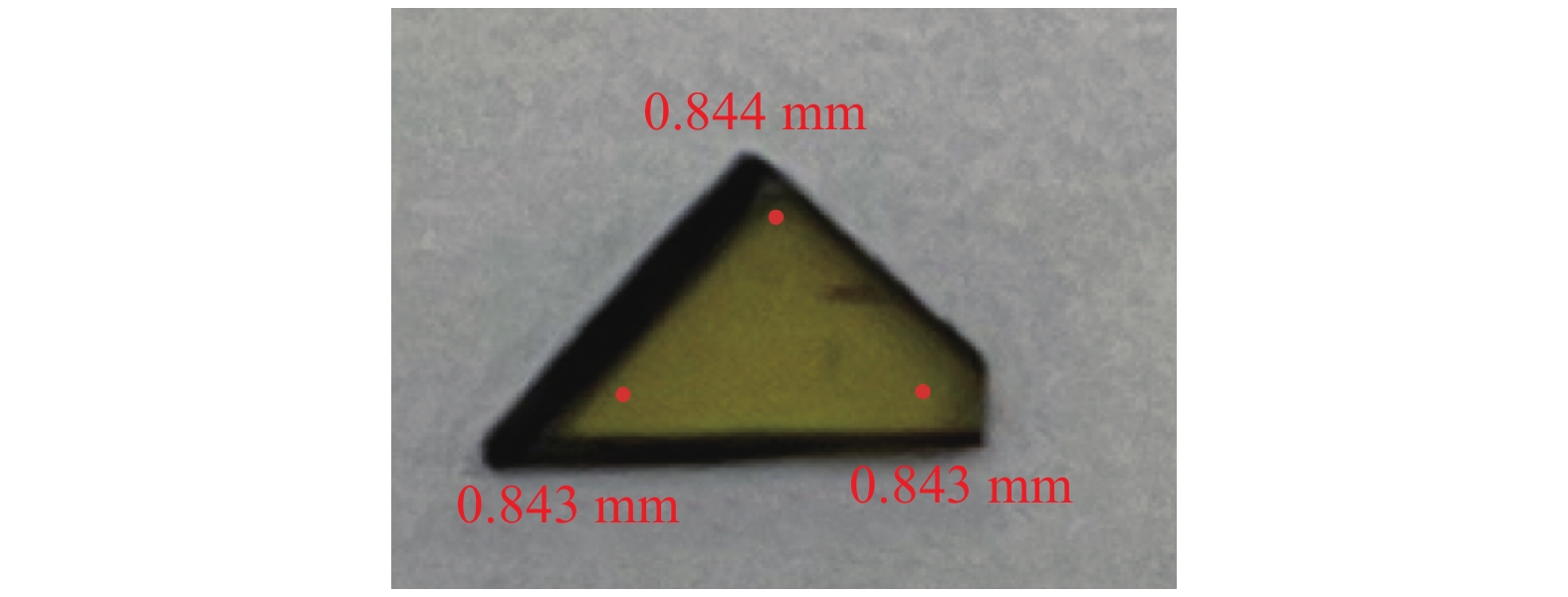

使用复享FX2000高速光纤光谱仪通过观察窗OB1-OB4对ECR微波等离子体进行诊断,光谱仪波长测量范围为197~847 nm,最佳光学分辨率为0.05 nm,积分时间设定为4 ms,积分次数500次。通过光学显微镜对样品外延生长面进行形貌表征,并用千分尺对生长厚度进行测量以表征其生长速率。样品表面平整程度会影响千分尺测量误差从而导致速率计算误差。针对这一问题,采用以下两种测量方法以减小速率计算误差:(1)使用高精度金刚石抛光机对种晶进行抛光,种晶表面平整度最大相差1 µm,且生长前对种晶厚度进行拍照标记,如图2所示,生长后使用千分尺尽可能测量相同的点。(2)确定同一种晶表面无厚度差的A,B两区域,生长过程中A覆盖极薄的金刚石覆盖层以阻断等离子体与其接触从而阻止A区金刚石的生长,生长后酒精超声清洗及擦拭生长表面以除去A区可能生长的无定形碳膜,再使用千分尺测量A、B两区域的厚度差从而确定生长厚度。

-

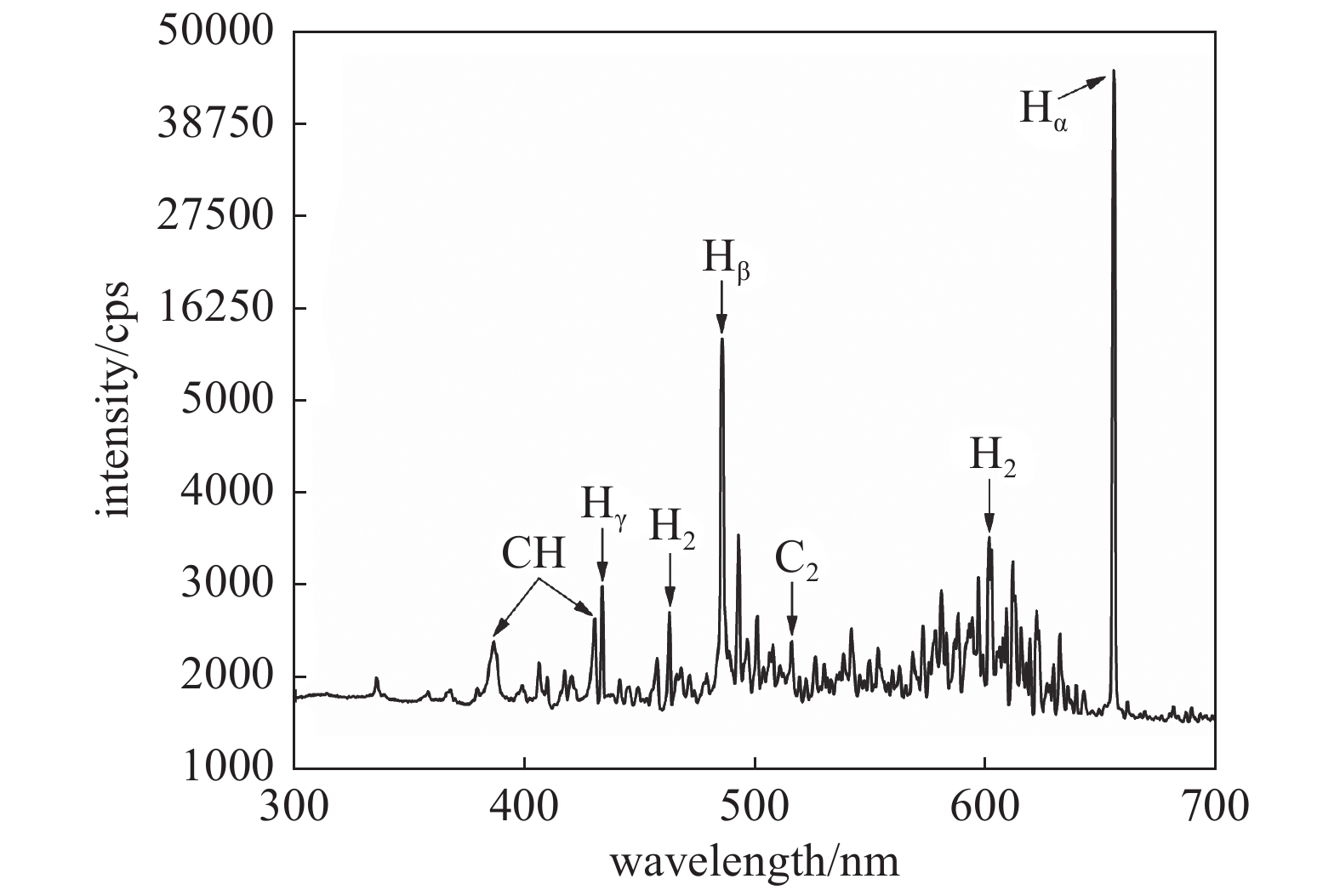

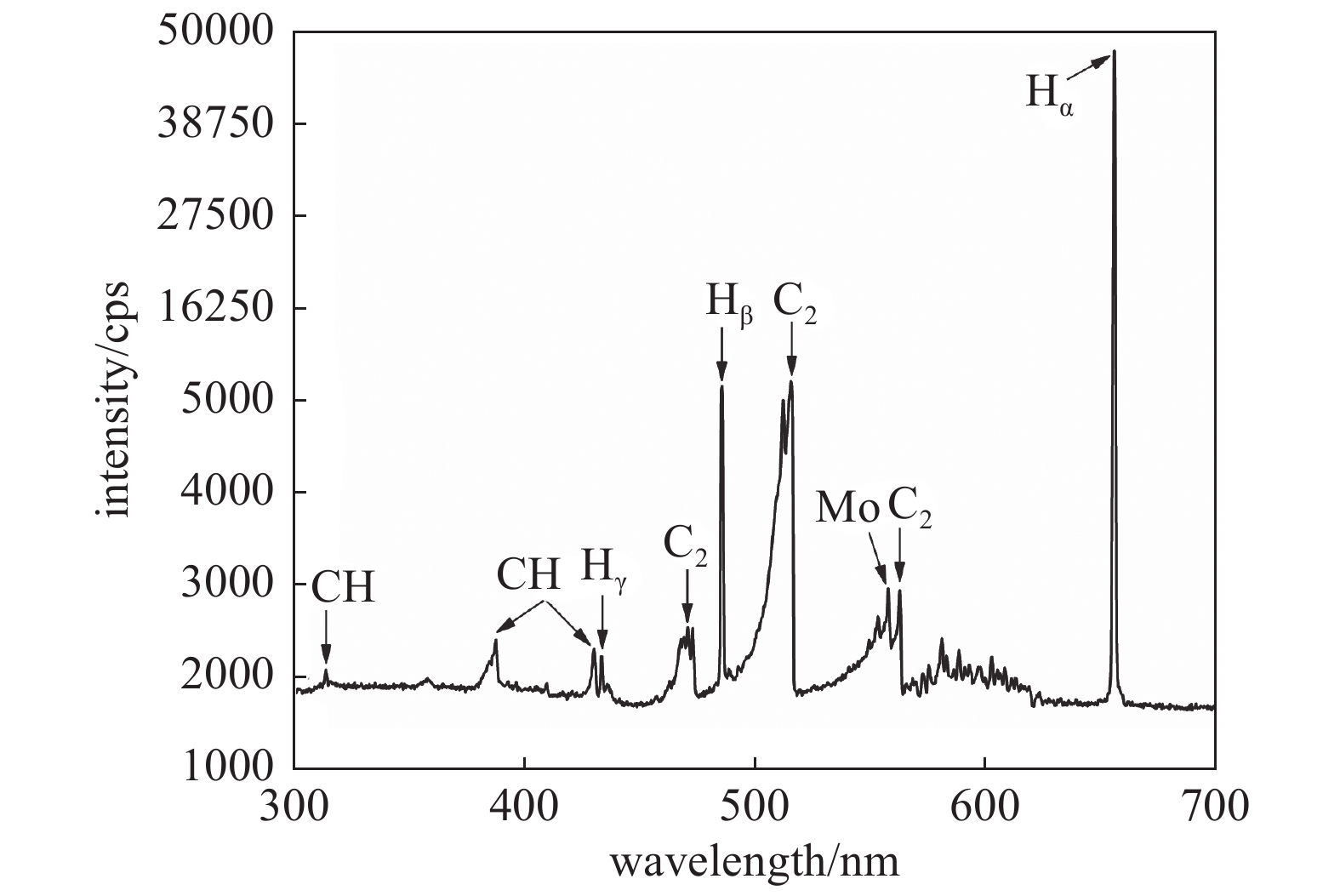

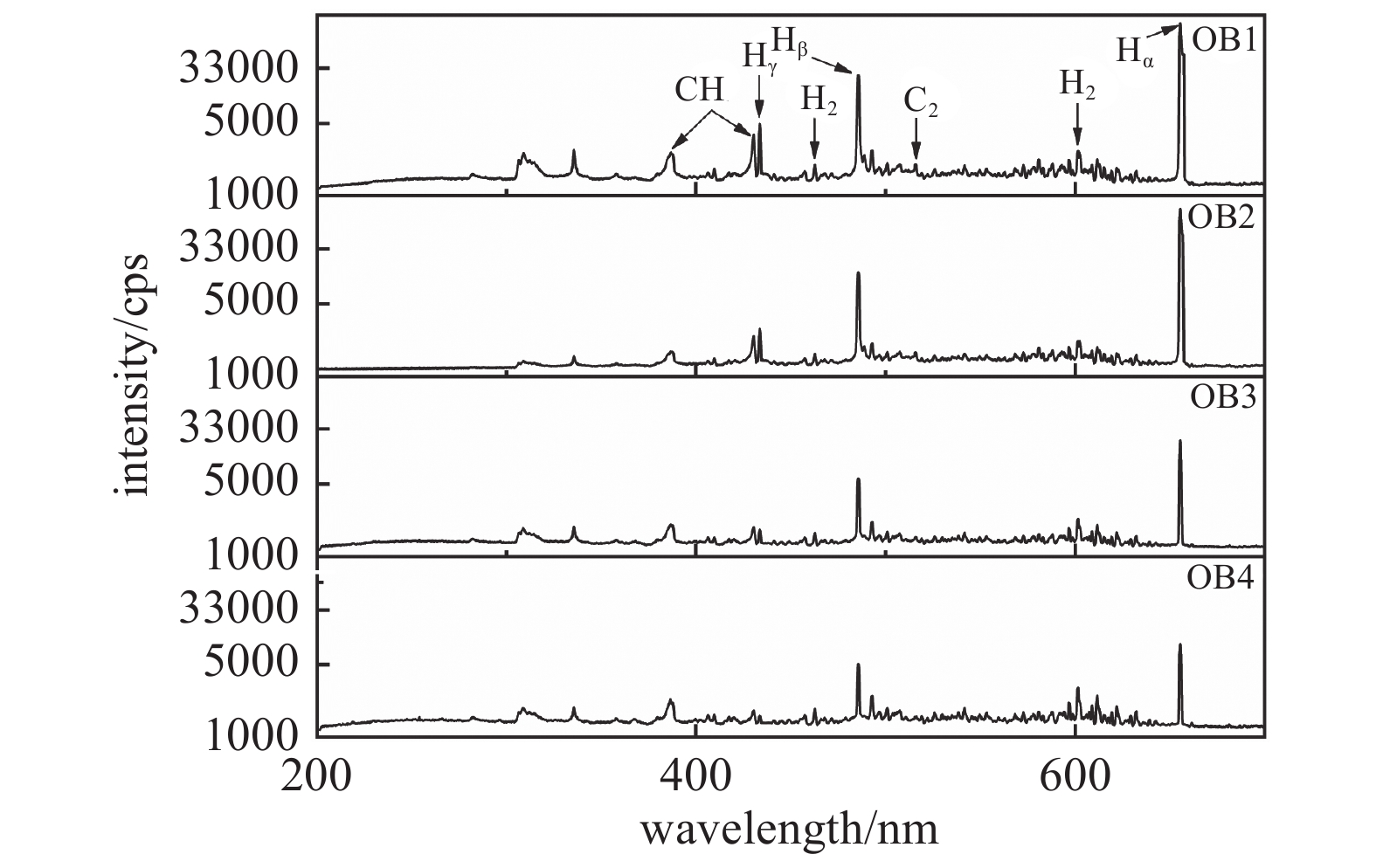

图3为观察窗OB1采集CH4/H2 ECR微波等离子体发射光谱图,微波功率1200 W,工作气压0.8 Pa,H2流量50 mL/min ,CH4浓度为3%;图4为本实验室双基片台MPCVD装置[19]微波等离子体发射光谱图,运行气压15 kPa,保持其他参数条件不变。发现CH4/H2体系下,ECR微波等离子体与运行于中高气压15 kPa下微波等离子体中的基团种类基本相同,皆主要存在H原子Balmer线系(Hα:656.30 nm, Hβ:486.25 nm, Hγ:434.09 nm), CH(431.34 nm, A2Δ→X2П)和C2 Swan带(471 nm, 516.54 nm, 563.10 nm)[20]。但有所区别的是ECR微波等离子体中含碳基团主要为CH基团,C2基团谱线强度非常弱且存在未解离的H2,认为是ECR微波等离子体的功率密度低,不足以完全解离H2激发足够多的C2基团。

-

为减少等离子体对石英窗口的刻蚀引起的等离子体污染,有必要将磁场共振区尽可能远离石英窗口。为此研究了磁场线圈的位置对磁场共振区位置的影响。为避免基片台对等离子体放电的影响,将基片台置于距石英窗口最远距离处。将B组线圈固定于z=200 mm处,调节A组线圈位置,当线圈距离分别为120、130、140 mm时磁场共振区皆在观察窗OB1-OB2附近,如图5所示。当线圈距离为130 mm时磁场共振区位于距离石英窗口85~190 mm区域,利用高速光纤光谱仪分别从观察窗OB1、OB2、OB3、OB4轴向对反应腔内等离子体进行光谱测量以研究等离子体沿z轴轴向空间分布,光谱结果如图6所示,处于共振区的OB1和OB2窗口附近等离子体发射光谱较强,但OB2处ECR等离子体中各基团强度相比于OB1处有所减弱,这是由于微波在共振区沿轴向传输的过程中微波能量被等离子体吸收从而逐渐递减,磁场强度从OB2轴向向下至OB4处梯度下降,等离子体中各基团强度均呈减弱趋势,是由于活性粒子轴向向下扩散的过程中与中性粒子的频繁碰撞而能量逐渐损失所导致的[21]。因此将基片台置于磁场共振区区域将更有利于单晶金刚石的生长。将样品台置于z=150 mm处磁场共振区,位于OB1下方,则微波能量主要聚集于石英窗口与样品台之间,增强微波等离子体基团强度的同时又不可避免的加剧了石英窗口的污染。如图5所示,当线圈距离减小且线圈整体远离石英窗口,磁场共振区呈远离石英窗口的趋势,且当线圈距离为120 mm时得到一个比较均匀的共振区,此时共振区位于距离石英窗口95~190 mm区域,因此通过线圈位置的调节优化磁场从而影响等离子体的分布以减少等离子体对石英窗口的刻蚀作用。

-

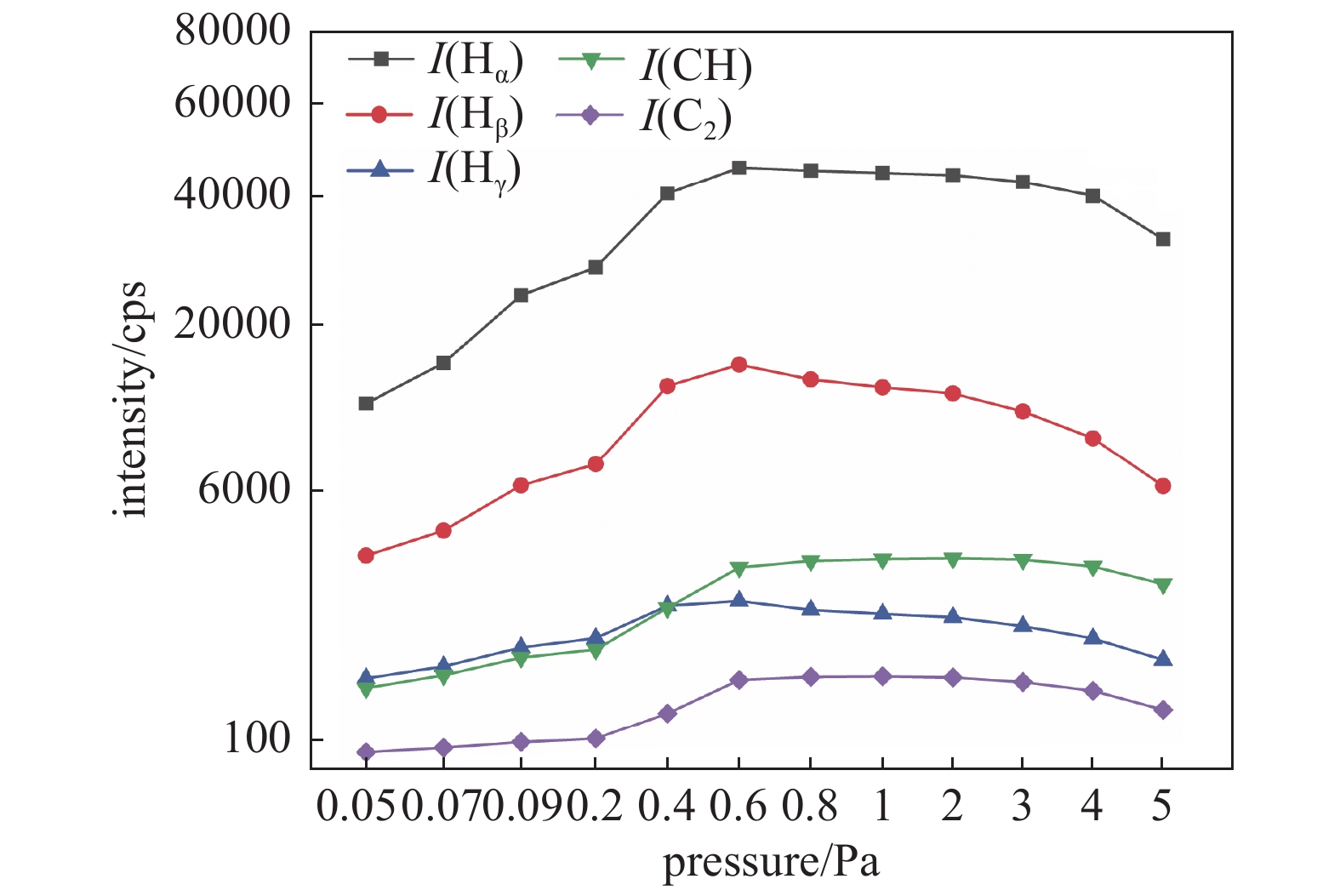

气压是影响微波等离子体中各基团浓度的重要参数之一[22],将样品台置于z=150 mm处,采用120 mm线圈距离所形成的磁场,微波功率1200 W,H2流量20 mL/min,甲烷浓度为3%,图7为随着气压升高从OB1窗口所采集基片台附近等离子体中各基团谱峰相对强度的变化,各基团谱峰相对强度皆呈先增强后减弱的趋势,Hα、Hβ、Hγ都在气压0.6 Pa附近时达到峰值,而CH和C2峰值则出现在0.8 Pa附近。在谱峰相对强度增强阶段,气体平均自由程随着气压的升高而减小,等离子体中粒子之间碰撞几率增大,气体离解更充分,从而活性基团浓度增加[22];而谱峰相对强度减弱阶段,由于气压进一步升高,反应腔内的粒子数增多,致使电子与中性粒子的碰撞更频繁,而微波功率不变,平均电子温度降低,进而降低了中性气体分子的离解率[23],且能观察到随着气压的升高等离子体基本聚集于石英窗口附近,这会对石英窗口造成更严重的刻蚀作用和更大的冷却压力。因此,需要选择一个合适的沉积气压。

-

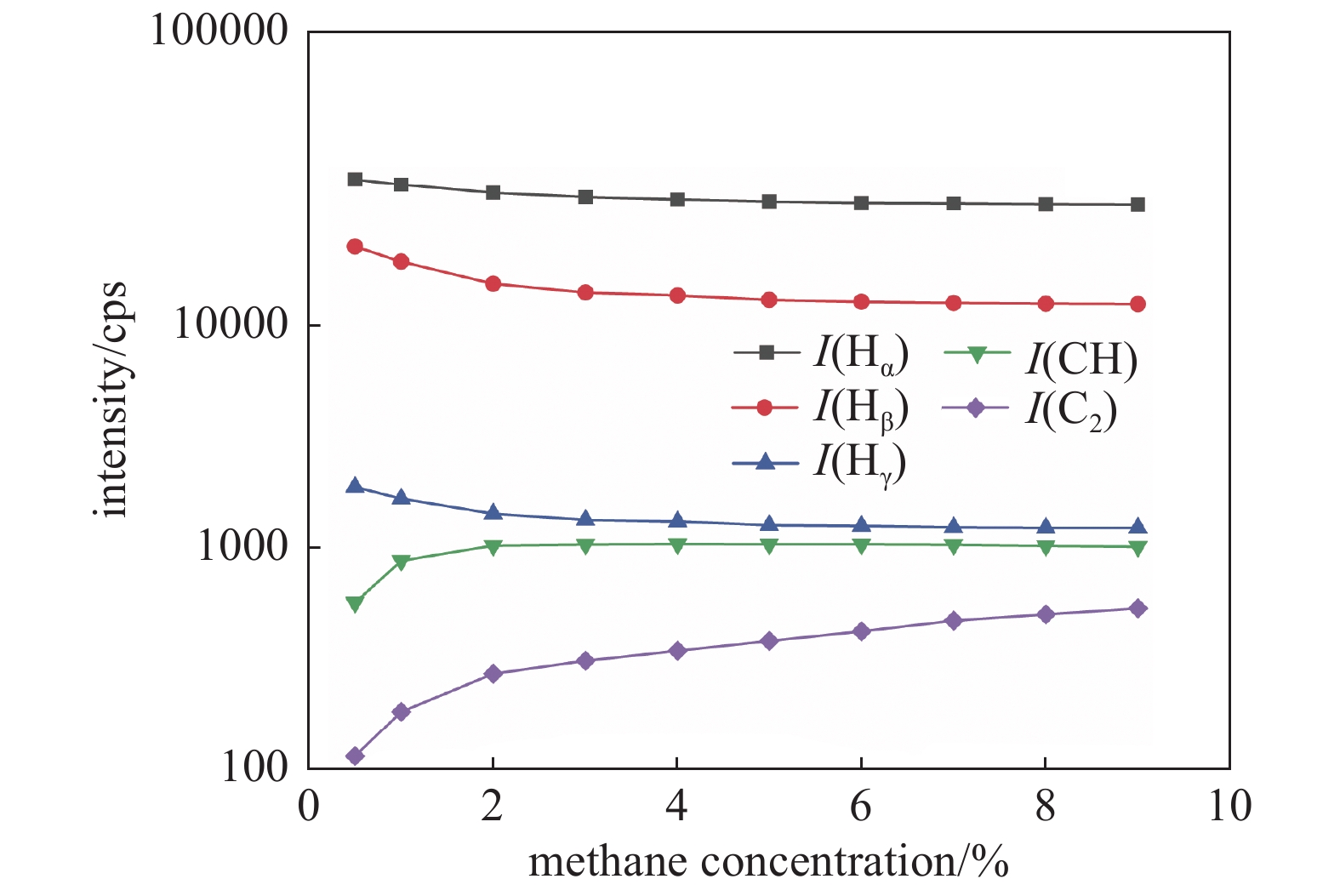

在CH4/H2体系微波等离子体沉积金刚石过程中,甲烷作为等离子体中含碳前驱体的唯一来源,甲烷浓度是沉积金刚石质量和速率的关键性参数[24]。图8为Hα、Hβ、Hγ、CH和C2谱峰相对强度随甲烷浓度变化的关系图,该图是在样品台置于z=150 mm处,采用120 mm线圈距离所形成的磁场,微波功率1200 W,H2流量50 ml/min,工作气压0.8 Pa条件下得到的。Hα基团相对强度不随甲烷浓度的增加而变化;甲烷浓度从0.5%增加到3%的过程中,Hβ和Hγ基团相对强度有所下降且同步变化,CH和C2基团相对强度则呈上升趋势,甲烷浓度进一步增加,Hα、Hβ、Hγ和CH基团相对强度都不再变化,而C2基团相对强度则还有缓慢的增强,但直到甲烷浓度增加到8%时C2相对强度仍均低于CH基团,这与图3所得CH基团强于C2基团的结果一致。

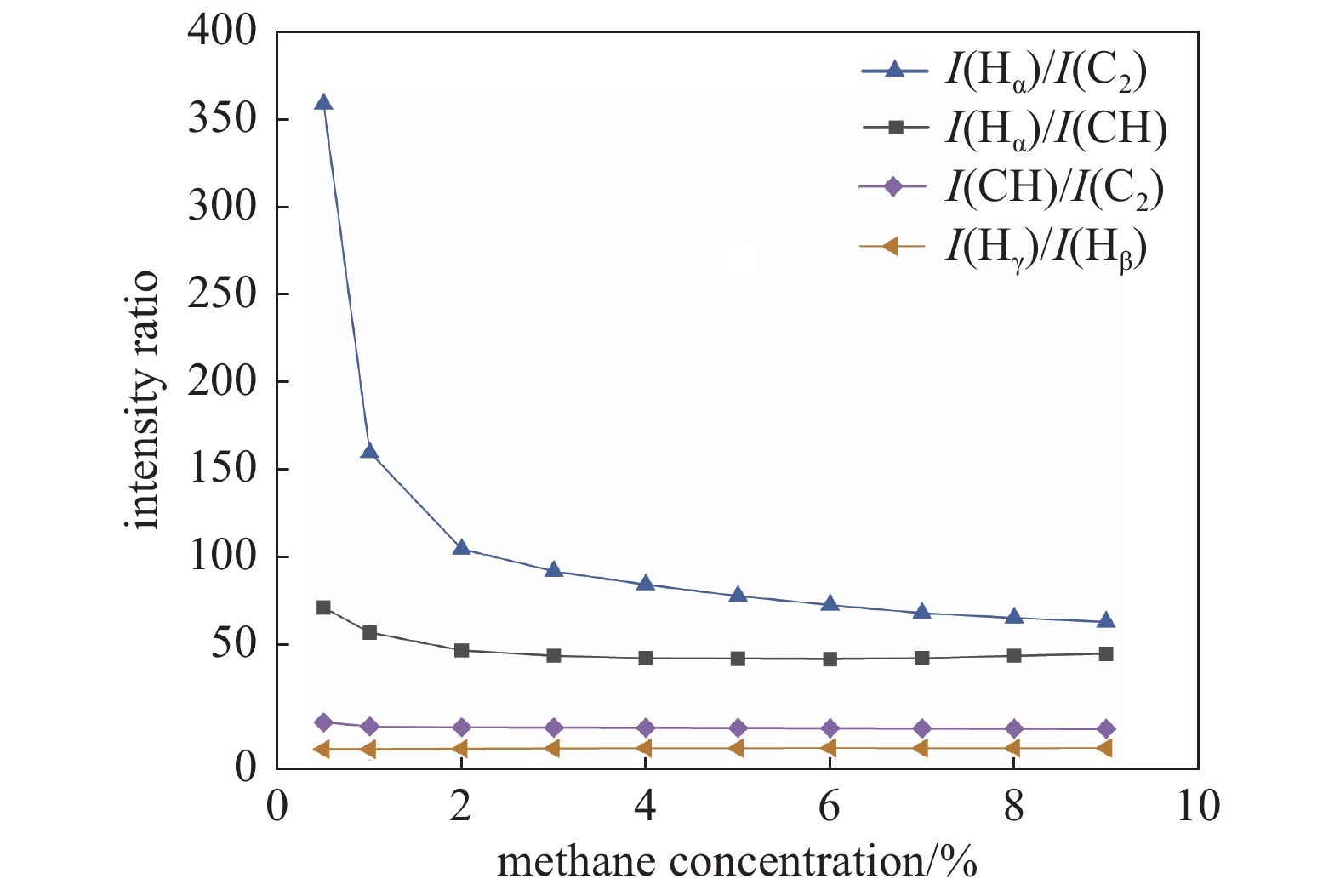

金刚石生长过程中,Hα是对非金刚石相起主要刻蚀作用的基团,但对于CH和C2何种基团为金刚石生长的前驱体尚有争论,有研究认为C2是非金刚石相生长的前驱体[25],而CH基团则被认为是金刚石生长的前驱体[26-27],图9为相对强度比值I(Hα)/I(C2)、I(Hα)/I(CH)、I(CH)/I(C2)、I(Hγ)/I(Hβ)随甲烷浓度的变化关系。I(Hα)/I(C2)、I(CH)/I(C2)被认为与金刚石的生长质量有关[20, 28, 29],而考虑到在ECR微波等离子体中含碳基团主要为CH基团,可以认为CH基团与金刚石相的生长有关,故而计算I(Hα)/I(CH);I(Hγ)/I(Hβ)与电子温度成正比。结合图8可以看出,I(Hα)/I(C2)在甲烷浓度从0.5%增加到2%的过程中急剧下降,随着甲烷浓度的进一步增加其值则缓慢减小并趋于饱和,是由于在甲烷浓度低于2%时C2基团谱峰相对强度过低,随后甲烷浓度继续升高而C2基团相对强度缓慢增强并也趋于饱和所致;I(Hα)/I(CH)在甲烷浓度低于3%时呈减小趋势随后也趋于饱和;I(CH)/I(C2)虽有减小的趋势但变化很小,这是由于甲烷浓度低于2%时两种基团相对强度同步变化,而甲烷浓度高于2%时,虽然C2基团相对强度缓慢增强但其浓度仍然较小,这结合图3可以得到;I(Hγ)/I(Hβ)不随甲烷浓度的升高而变化,证明ECR微波等离子体电子温度不随甲烷浓度的变化而变化。

-

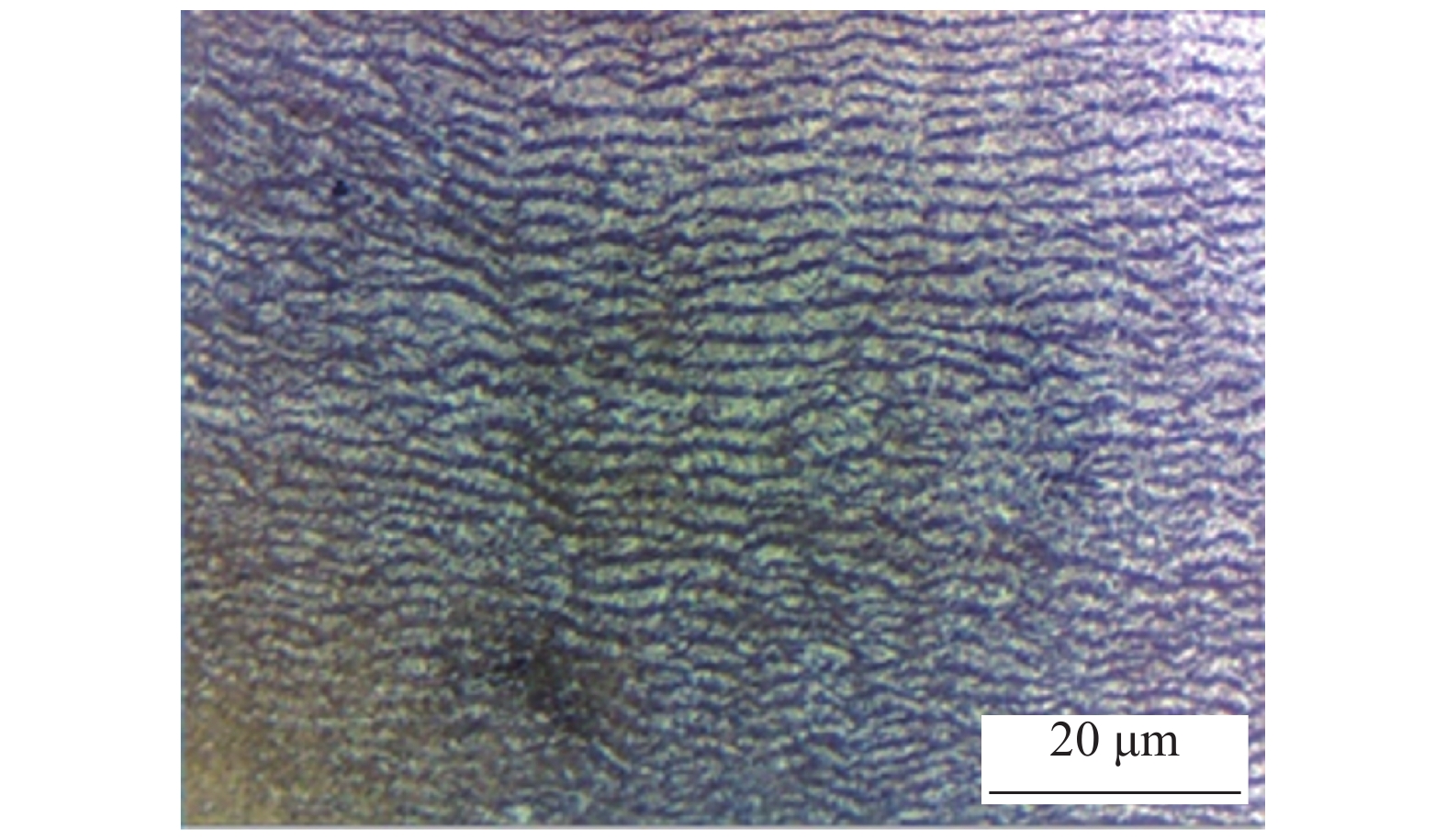

图10为光学显微镜下ECR微波等离子体同质外延生长单晶金刚石表面形貌,样品台位于观察窗OB1下方z=150 mm处,微波功率1200 W,氢气流量50 mL/min,甲烷浓度3%,工作气压为0.8 Pa。等离子体自加热为500℃左右,辅助加热650℃,则单晶金刚石种晶温度800℃左右,生长时间为10 h。如图,单晶金刚石生长面出现层状生长趋势,生长速率为200 nm/h,单晶金刚石主要有层状生长、岛状生长以及混合生长(层状/岛状生长)三种模式,而在含碳前驱体气氛等离子体生长单晶金刚石过程中,层状生长被认为更有利于生长出质量较好的单晶金刚石 [30],但生长台阶结构形态不规则且金刚石结晶状态不理想,认为是由于ECR微波等离子体功率密度低造成的,后续研究可以通过增加微波功率、寻求更精确的控温方式控制单晶金刚石种晶的生长温度及其他参数的深入研究来优化ECR微波等离子体生长单晶金刚石的工艺参数。

-

使用光谱仪对ECR微波等离子体进行诊断,在ECR-MPCVD装置上进行了单晶金刚石的同质外延生长,结论如下:在CH4/H2体系下,ECR微波等离子体与运行于中高气压下等离子体中所含基团种类相同,主要存在Hα、Hβ、Hγ、CH和C2基团,其中含碳基团以CH基团为主,且等离子体各基团谱峰相对强度在磁场共振区(875 Gs)较强,将基片台置于磁场共振区,基片台附近各基团谱峰相对强度随气压的升高先增强后减弱,I(Hα)、I(Hβ)、I(Hγ) 峰值在气压0.6 Pa附近,I(CH)和I(C2)峰值在0.8 Pa附近。气压不变,随甲烷浓度的增加,I(Hα)几乎不变,I(Hβ)和I(Hγ)先降低后趋于饱和,I(CH)和I(C2)先增强后趋于饱和;同时,I(Hα)/I(C2)先急剧下降后缓慢减小再趋于饱和,I(Hα)/I(CH)缓慢减小并趋于饱和,I(CH)/I(C2)和I(Hγ)/I(Hβ)基本不变。并在抛光的单晶金刚石表面生长得到了呈台阶状的外延层,生长速率为200 nm/h。

ECR-MPCVD 单晶金刚石外延生长研究

The Homoepitaxial Growth of Single Crystal Diamond with ECR-MPCVD

-

摘要: 借助高速光纤光谱仪对ECR微波等离子体进行实时诊断,研究了等离子体空间分布以及工作气压和甲烷浓度对等离子体发射光谱的影响,并在ECR-MPCVD设备上研究了单晶金刚石同质外延生长工艺。在CH4/H2体系下,ECR微波等离子体与运行于中高气压下等离子体中所含基团种类基本相同。且等离子体各基团谱峰相对强度沿磁场强度梯度下降的方向减弱,在磁场共振区(875 Gs)最强,将基片台置于磁场共振区,则基片台附近各基团谱峰相对强度随气压的升高先增强后减弱,I(Hα)、I(Hβ)、I(Hγ)峰值在气压0.6 Pa附近,I(CH)和I(C2)峰值在0.8 Pa附近。保持工作气压为0.8 Pa,甲烷浓度从0.5%增加到8%的过程中,I(Hα)几乎不变,I(Hβ)和I(Hγ)先降低后趋于饱和,I(CH)和I(C2)先增强后趋于饱和;I(Hα)/I(C2)先急剧下降后缓慢减小再趋于饱和,I(Hα)/I(CH)缓慢减小并趋于饱和,I(CH)/I(C2)和I(Hγ)/I(Hβ)基本不变。以微波功率1200 W,氢气流量50 mL/min,甲烷浓度3%,工作气压0.8 Pa,金刚石种晶温度800℃的条件下生长10 h,在抛光的单晶金刚石表面得到了呈台阶状生长的外延层,生长速率为200 nm/h。

-

关键词:

- 电子回旋共振微波等离子体 /

- 等离子体发射光谱 /

- 单晶金刚石外延生长

Abstract: In order to explore the homoepitaxial growth of single crystal diamond at low pressure and low rate by ECR-MPCVD, the real-time diagnosis of ECR microwave plasma was carried out with a high-speed optical fiber spectrometer, and the spatial distribution of plasma was studied, then the effects of pressure and methane concentration were investigated in detail on plasma emission spectrum. In the CH4/H2 atmosphere system, the kinds of groups in ECR microwave plasma were the same as those in the plasma operating at medium and high pressure basically. The intensity of plasma emission spectra of each group decreased along the direction of magnetic field intensity gradient decline, and the intensity of plasma emission spectra of each group was strongest in the magnetic field resonance region (875 Gs). When the substrate was placed in the magnetic field resonance region, the relative intensity of each group near the substrate showed a trend of increase at first and then decreased with the increase of the pressure, and when the pressure was near about 0.6 Pa, the Hα, Hβ and Hγ groups had the strongest emission spectra, while the intensity peaks of CH and C2 groups appeared near about 0.8 Pa. Then keeping the working pressure at 0.8 Pa, when the methane concentration increased from 0.5% to 8%, the intensity of Hα group remained unchanged almost, and the relative intensity of the Hβ and Hγ groups showed a trend of decrease at first and then invariability, and the relative intensity of the CH and C2 groups showed a trend of increase at first and then stabilization; I(Hα)/I(C2) decreased sharply at first, then slowly decreased and then tended to stabilization; I(Hα)/I(CH) slowly decreased and tended to invariability; I(CH)/I(C2) and I(Hγ)/I(Hβ) remained unchanged almost. With the microwave power of 1200 W, the hydrogen flow rate of 50 mL/min, the methane concentration of 3%, the working pressure of 0.8 Pa, and the single crystal diamond seed temperature of 800℃, step growth formed on the polished surface of single crystal diamond when growing for 10 hours, and the growth rate was 200 nm/h.-

Key words:

- ECR microwave plasma /

- OES /

- Homoepitaxial growth of single crystal diamond .

-

-

-

[1] Thomas R,Rudder R,Markunas R. Thermal desorption from hydrogenated and oxygenated diamond (100) surfaces[J]. Journal of Vacuum Science & Technology A:Vacuum, Surfaces, and Films,1992,10(4):2451−2457 [2] Wang W H,Dai B,Wang Y,et al. Recent progress of diamond optical window-related components[J]. Materials science and technology,2020,28(3):42−57 (王伟华,代兵,王杨,等. 金刚石光学窗口相关元件的研究进展[J]. 材料科学与工艺,2020,28(3):42−57(in chinese) Wang W H, Dai B, Wang Y, et al. Recent progress of diamond optical window-related components[J]. Materials science and technology, 2020, 28(03): 42-57 [3] Raynaud C, Tournier D, Morel H, et al, Comparison of high voltage and high temperature performances of wide bandgap semiconductors for vertical power devices[J]. Diamond and related materials, 2010, 19(1): 1-6 [4] Umezawa H,Nagase M,Kato Y,et al. High temperature application of diamond power Device[J]. Diamond and related materials,2012,24201-205 [5] Song Y,Fang C,Mu Y,et al. Relationship between Co-related optical centres and nitrogen impurities in large single crystals of diamond grown in Co–C system under HPHT conditions[J]. Cryst Eng Comm,2023 [6] Gao D,Ma Z B. Two-dimensional expansion of single crystal diamond growth by MPCVD[J]. Chinese journal of vacuum science and technology,2022,42(7):541−546 (高登,马志斌. MPCVD二维扩大生长单晶金刚石[J]. 真空科学与技术学报,2022,42(7):541−546(in chinese) Gao D, Ma Z B. Two-dimensional expansion of single crystal diamond growth by MPCVD[J]. Chinese journal of vacuum science and technology, 2022, 42(07): 541-546 [7] Donato N,Rouger N,Pernot J,et al. Diamond power devices: state of the art, modelling, figures of merit and future perspective[J]. Journal of Physics D: Applied Physics,2019,53(9):093001 [8] Achard J,Jacques V,Tallaire A. CVD diamond single crystals with nv centres: a review of material synthesis and technology for quantum sensing applications[J]. Journal of Physics D:Applied Physics,2020,53(31):313001 doi: 10.1088/1361-6463/ab81d1 [9] Lenzini F, Gruhler N, Walter N, et al, Diamond as a platform for integrated quantum photonics[J]. Advanced Quantum Technologies, 2018, 1(3): 1800061 [10] Schirhagl R,Chang K,Loretz M,et al,Nitrogen-vacancy centers in diamond:nanoscale sensors for physics and biology. Annu[J]. Rev. Phys. Chem,2014,65(1):83−105 doi: 10.1146/annurev-physchem-040513-103659 [11] Marinelli M,Prestopino G,Tonnetti A,et al. A novel synthetic single crystal diamond device for in vivo dosimetry[J]. Medical Physics,2015,42(8):4636−4644 doi: 10.1118/1.4926556 [12] Shimaoka T, Koizumi S, JH, et al, Recent progress in diamond radiation detectors[J]. Functional Diamond, 2022, 1(1): 205-220 [13] Liao M. Progress in semiconductor diamond photodetectors and MEMS sensors[J]. Functional Diamond,2022,1(1):29−46 [14] Robledo L,Childress L,Bernien H,et al. High-fidelity projective read-out of a solid-state spin quantum register[J]. Nature,2011,477(7366):574−578 doi: 10.1038/nature10401 [15] Kunze M,Vescan A,Dollinger G,et al. δ-doping in diamond[J]. Carbon,1999,37(5):787−791 doi: 10.1016/S0008-6223(98)00272-3 [16] 衡凡. MPCVD制备氮掺杂单晶金刚石的研究[D]. 湖北: 武汉工程大学, 2020 Heng F. Study on preparation of nitrogen-doped single crystal diamond by MPCVD[D]. Wuhan Institute of Technology, 2022 [17] Pelletier J,Anders A. Plasma-based Ion implantation and deposition: a review of physics, technology, and applications[J]. IEEE Transactions on Plasma Science,2005,33(6):1944−1959 doi: 10.1109/TPS.2005.860079 [18] Luo L, Wu W, Zhu Y, et al, Spectrum analysis of plasma in CH4/H2 and CH4/He systems[J]. High Power Laser and Particle Beams, 2008, 20(6): 899-902 [19] Xia Y H,Li Y C,Geng C W,et al. Influence of dual-substrate structure on growth of single diamond by MPCVD[J]. Diamond & Abrasives Engineering,2018,38(3):1−5 (夏禹豪,李艳春,耿传文,等. MPCVD中双基片台结构对单晶金刚石生长的影响[J]. 金刚石与磨料磨具工程,2018,38(3):1−5(in chinese) doi: 10.13394/j.cnki.jgszz.2018.3.0001 Xia Y H, Li Y C, Geng C W, et al. Influence of dual-substrate structure on growth of single diamond by MPCVD[J]. Diamond & Abrasives Engineering, 2018, 38(03): 1-5 doi: 10.13394/j.cnki.jgszz.2018.3.0001 [20] Wu C,Ma Z B,Gao P,et al. Growth and emission spectra analysis of single crystal diamond by MPCVD[J]. Journal of Synthetic Crystals,2015,44(10):2734−2738 (吴超,马志斌,高攀,等. MPCVD生长单晶金刚石及发射光谱分析[J]. 人工晶体学报,2015,44(10):2734−2738(in chinese) Wu C, Ma Z B, Gao P, et al. Growth and emission spectra analysis of single crystal diamond by MPCVD[J]. Journal of Synthetic Crystals, 2015, 44(10): 2734-2738 [21] Shen W L,Ma Z B,Tan B S. The effects of magnetic field configuration on the electron parameters of microwave ECR plasma[J]. Journal of Wuhan Institute of Technology,2010,32(9):53−57 (沈武林,马志斌,谭必松. 磁场位形对微波ECR等离子体电子参数的影响[J]. 武汉工程大学学报,2010,32(9):53−57(in chinese) Shen W L, Ma Z B, Tan B S. The effects of magnetic field configuration on the electron parameters of microwave ECR plasma[J]. Journal of Wuhan Institute of Technology, 2010, 32(09): 53-57 [22] Huang H W,Zhang T T,Ding K J,et al. Optical emission spectroscopy analysis of diamond deposited by MPCVD[J]. Journal of Wuhan Institute of Technology,2017,39(1):39−44 (黄宏伟,张田田,丁康俊,等. MPCVD制备金刚石中的光谱分析[J]. 武汉工程大学学报,2017,39(1):39−44(in chinese) Huang H W, Zhang T T, Ding K J, et al. Optical emission spectroscopy analysis of diamond deposited by MPCVD[J]. Journal of Wuhan Institute of Technology, 2017, 39(01): 39-44 [23] Heng F,Liao X H,Cao W,et al. Carben nanowalls modifying single crystal diamond by ECR microwave plasma[J]. Diamond & Abrasives Engineering,2020,40(1):34−38 (衡凡,廖学红,曹为,等. ECR微波等离子体对单晶金刚石表面的碳纳米墙修饰[J]. 金刚石与磨料磨具工程,2020,40(1):34−38(in chinese) Heng F, Liao X H, Cao W, et al. Carben nanowalls modifying single crystal diamond by ECR microwave plasma[J]. Diamond & Abrasives Engineering, 2020, 40(01): 34-38 [24] Luo L X,Wu W D,Sun W G,et al. Diagnosis of low-pressure methane plasma by optical emission spectroscopy[J]. Chinese journal of vacuum science and technology,2007(3):203−207 (罗利霞,吴卫东,孙卫国,等. 低压甲烷等离子体发射光谱诊断[J]. 真空科学与技术学报,2007(3):203−207(in chinese) Luo L X, Wu W D, Sun W G, et al. Diagnosis of low-pressure methane plasma by optical emission spectroscopy[J]. Chinese journal of vacuum science and technology, 2007(03): 203-207 [25] Han S-B. Effect of oxygen for diamond film synthesis with C-hexane in microwave plasma enhanced CVD process[J]. Journal of Electrical Engineering and Technology,2012,7(6):983−989 doi: 10.5370/JEET.2012.7.6.983 [26] Richley J C,Kelly M W,Ashfold M N,et al. Optical emission from microwave activated C/H/O gas mixtures for diamond chemical vapor deposition[J]. The Journal of Physical Chemistry A,2012,116(38):9447−9458 doi: 10.1021/jp306191y [27] Liao Y,Li C,Ye Z,et al. Analysis of optical emission spectroscopy in diamond chemical vapor deposition[J]. Diamond and Related Materials,2000,9(9-10):1716−1721 doi: 10.1016/S0925-9635(00)00283-1 [28] Elliott M,May P,Petherbridge J,et al. Optical emission spectroscopic studies of microwave enhanced diamond CVD using CH4/CO2 plasmas[J]. Diamond and Related Materials,2000,9(3-6):311−316 doi: 10.1016/S0925-9635(99)00196-X [29] Liao W H,Lin C R,Wei D H. Effect of CH4 concentration on the growth behavior, structure, and transparent properties of ultrananocrystalline diamond films synthesized by focused microwave Ar/CH4/H2 plasma jets[J]. Applied Surface Science,2013,270324-330 [30] Tyagi P K,Misra A,Unni K N,et al. Step growth in single crystal diamond grown by microwave plasma chemical vapor deposition[J]. Diamond and related materials,2006,15(2-3):304−308 doi: 10.1016/j.diamond.2005.08.054 -

首页

首页 登录

登录 注册

注册

下载:

下载: