-

DLC涂层具有良好的耐蚀性、耐磨性,高硬度和化学稳定性好等优点,被广泛用于机械电子、生物医学、航空航天等领域的固体润滑与防护[1-4]。因sp3与sp2杂化C原子价键之间交联扭曲引起内应力和DLC涂层与工件基体之间的热膨胀系数差异引起的热应力[5],使得DLC涂层内应力较大,导致涂层易发生剥落失效[6],限制了其在重载高速等恶劣服役环境中的应用。为了提高DLC涂层环境的适应性,通过不同种类的元素掺杂,能够实现对DLC涂层的性能有效调控[7-8],利用掺杂金属纳米相提升涂层的韧性[9],提高DLC涂层的耐磨性能[10]。掺杂元素能改变DLC中C原子网络的成键方式[11-13],降低内应力并改善涂层的脆性[14],提高涂层的环境适应性,这种多相复合结构可以增强耐磨涂层的机械强度和韧性,减小涂层的内应力[15]。如掺杂金属W形成纳米晶−非晶复合结构,可增强韧性、提高结合力[16-17],掺杂Cr可提高涂层的抗裂性和附着力[18],Fe和W共掺杂制备的涂层表现出低摩擦系数、磨损率[19]。WC掺杂DLC(WC-DLC)纳米复合涂层由于其良好的力学和摩擦学性能,被广泛应用于航空航天、机械加工等领域,其中磁控溅射制备WC-DLC 涂层组织致密,性能优良且工艺调节性好[20-21]。元素掺杂过程中,可以通过改变C2H2气体流量或百分比影响靶材溅射产额,进而影响AlCrSi等元素掺杂DLC涂层结构和非晶碳含量,也能够调节掺杂DLC涂层中掺杂元素含量,从而显著改变涂层的力学和摩擦学性能[22-23]。

作为制备WC-DLC涂层工艺过程中的重要影响因素, C2H2流量对WC-DLC涂层的影响机理研究目前相对较少,本文以C2H2气体流量作为研究对象,探究了C2H2气体流量对WC-DLC涂层的物相结构,晶粒大小,涂层粗糙度及力学和摩擦学性能的影响。

-

实验采用自主研制的全方位多功能真空复合镀膜设备,待强化基体材料为9310齿轮钢,尺寸为Φ 30 mm×9 mm,所有试样均用砂纸打磨后对表面进行抛光处理,随后在丙酮和酒精中进行超声清洗并烘干以清除油脂等污染物,最后将试样放置在镀膜设备中。实验采用的靶材为WC (99.95%)靶,镀膜前先将设备抽真空至5×10−2 Pa,加热至200℃时对试样进行离子辉光清洗,通入纯度为99.999%的氩气,在2 Pa气压下在基体表面施加−1000 V偏压,利用高能氩离子轰击35 min以清除样品表面的杂质和水分。为了进一步提高WC-DLC涂层和齿轮钢基体之间的结合力,实现金属和非金属之间的良好过渡,在沉积DLC之前利用Cr靶(99.95%)在基体表面沉积一层Cr和CrN过渡层,因此WC-DLC涂层与齿轮钢基体过渡层结构为Cr/CrN涂层[24]。沉积Cr过渡层时,把直流电源接到Cr靶上,电流为3 A,同时在基体上连接−100 V直流偏压,向反应腔体内通入氩气,磁控溅射沉积纯Cr 过渡层;接下来,调节直流电源的电流为5 A,氩气流量不变,同时还通入N2,改变偏压为−75 V,沉积CrN 过渡层。

最后将WC靶接入直流电源,电源功率不变,氩气流量不变以制备DLC涂层,为了研究不同C2H2气体流量对制备WC-DLC涂层性能的影响,C2H2气体流量分别控制为10,20,30,40,50 mL/min,溅射反应时间为60 min,具体实验参数如表1所示。

-

采用ZEISS SUPRA 55场发射扫描电子显微镜(SEM)观察涂层的表面形貌和断面形貌。采用日本理学X射线衍射仪Rigaku MiniFlex 600分析涂层的物相结构。采用Nano-Indentor G200纳米压痕仪测试涂层的硬度,压入深度为400 nm,根据压痕过程中采集的压力和压入深度关系得到的载荷-压深曲线来分析涂层的硬度和弹性模量[25]。为了对比涂层的结合强度,采用洛氏压痕法在涂层表面通过压头施加合适的载荷,压入涂层试样,载荷大小为150 kg,保持载荷15 s,通过光镜观察压痕周围涂层的剥落情况以判断涂层结合强度。

-

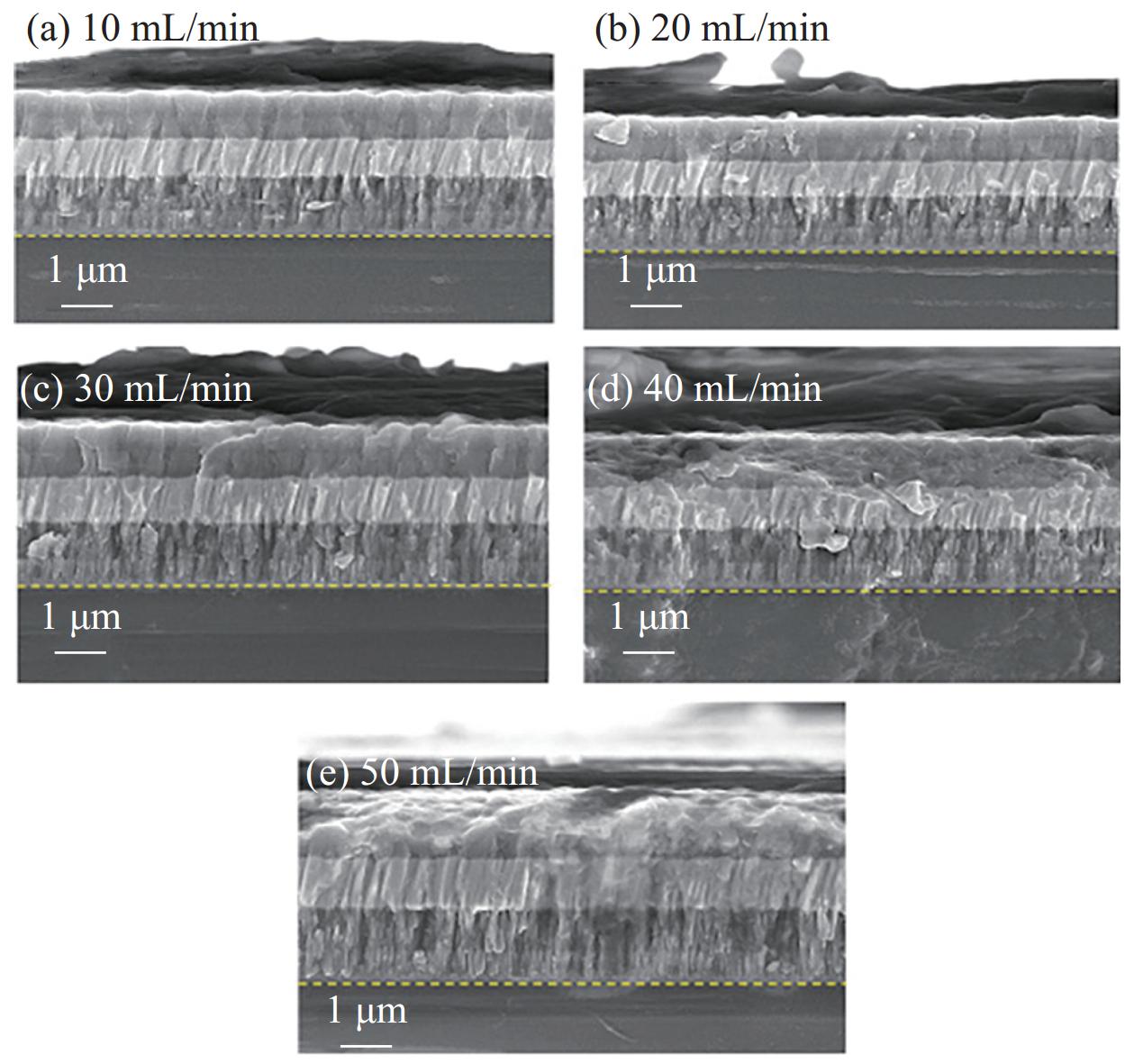

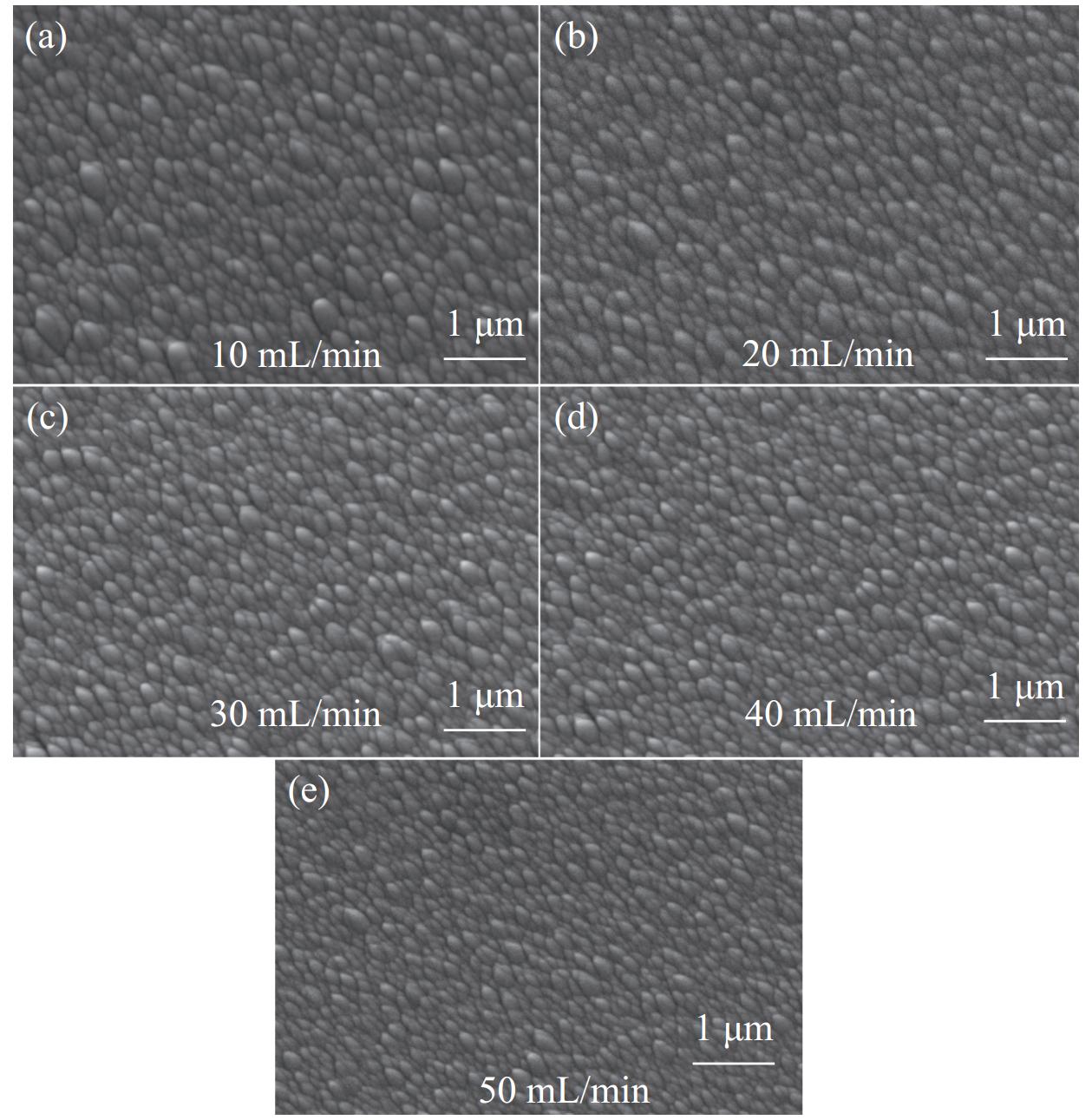

图1为不同C2H2气体流量下制备的齿轮钢耐磨涂层的表面形貌,随着乙炔气体流量的增加,WC靶溅射效率降低,沉积粒子的减少抑制了WC晶粒的快速生长,使涂层整体的晶粒更加细化致密。

图2为以Cr/CrN为过渡层,在不同乙炔流量下制备的WC-DLC 涂层的断面形貌。在乙炔流量较小情况下,金属离子较多,涂层生长较快。当乙炔流量增大时,柱状晶粒逐渐消失,晶粒变得更加密实,出现细化和非晶化。涂层表面的WC-DLC晶粒随着乙炔流量的不断增加,抑制了柱状晶的快速生长,使晶粒出现不断细化并逐渐呈现非晶化趋势,同时涂层变得更加致密。

-

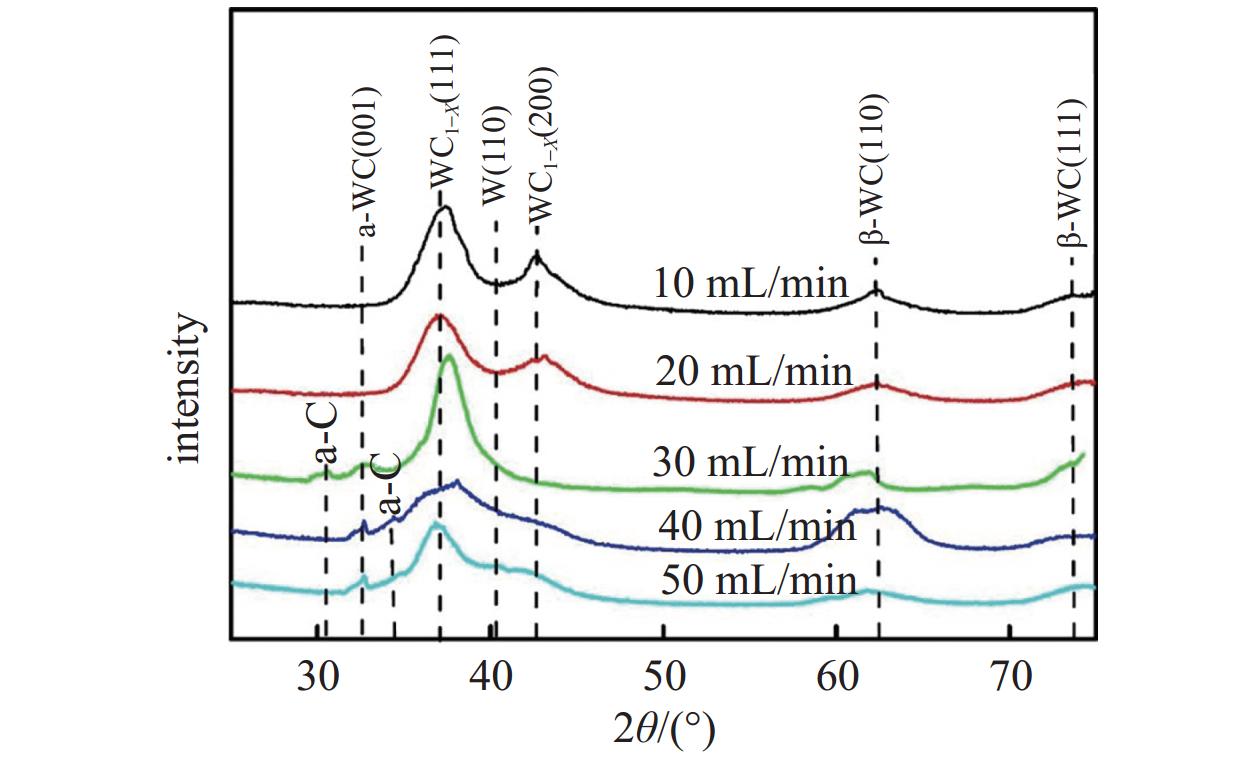

采用 XRD 表征了不同乙炔气体流量下W掺杂的复合涂层物相组成,如图3所示。当C2H2气体流量较低时,C原子含量低,涂层中的物相主要包括WC1-x(2θ=37.0°,42.9°)和β-WC相(2θ=64.0°)。随着C2H2气体流量增加,WC1-x相逐渐减少,出现大量的非晶碳相(a-C)(2θ=30.5°,34.6°)和α-WC相(2θ=31.5°),碳氢离子团在表面聚集。整体而言,WC-DLC涂层表现出典型的非晶态特征,伴随有WC纳米晶形成。

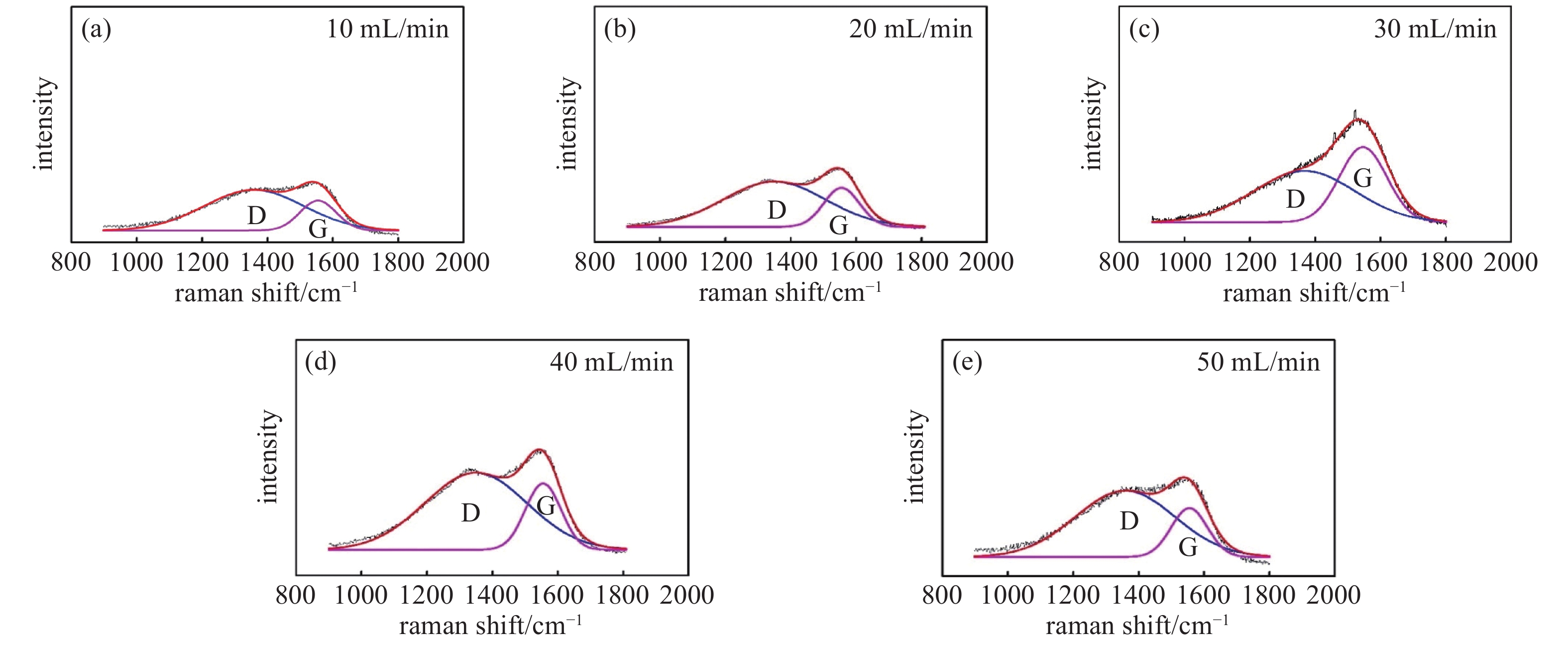

通过对不同C2H2气体流量下制备WC-DLC 涂层拉曼图谱进行高斯拟合处理,结果如图4所示,根据拟合结果可得到D峰和G峰的峰位,半峰高宽,ID/IG等数据,如表2所示。DLC的拉曼光谱在1000 cm−1~1800 cm−1之间出现了一个不对称的“骆驼状”宽峰,高斯拟合可得到位于 1350 cm−1左右的D峰和 l580 cm−1左右的G 峰,呈现出了DLC涂层的典型特征峰,这说明实验中所制备的涂层均含有类金刚石相,同时结合图3中XRD物相分析,涂层中有WC,W2C等物相,可判断涂层为WC-DLC涂层。D 峰与 G 峰的强度之比(ID/IG)反映了涂层中 sp2和 sp3的相对比例,直接影响着 WC-DLC涂层的力学性能。若ID/IG的比值越小,DLC结构中 sp3杂化C原子含量越高;若ID/IG比值越大,sp2杂化C原子含量越高。

从拉曼光谱图4中可以看出,当乙炔气体流量为10 mL/min时,反应腔室中碳离子较少,D峰和G峰强度都较小,ID/IG为3.24,涂层中类金刚石相较少;乙炔气体流量不断增加,D峰峰位从10 mL/min时1358 cm−1漂移到20 mL/min的1352 cm−1,30 mL/min的1356 cm−1,40 mL/min的1351 cm−1;G 峰峰位先向低波段移动,然后再向高波段移动到1558 cm−1,G峰半峰宽(FWHM)由126.6增加到137.4,然后在50 mL/min时为131.7,ID/IG值从10 mL/min时3.54降低到30 mL/min时为1.67,在50 mL/min时升高为2.61。这说明随着乙炔气体流量不断增加,反应室中离子碰撞几率增加,乙炔气体电离出更多的碳氢离子团,WC-DLC涂层中 sp3-C 含量增加,当乙炔气体流量进一步增加到 50 mL/min 时,G 峰峰位从1546 cm−1漂移到 1554 cm−1,G 峰的半峰宽(FWHM)从30 mL/min时137.4减小到131.7,ID/IG从 30 mL/min时的1.67增加到2.61,表明WC-DLC涂层中sp3键的含量随乙炔流量的增加而减少,sp2杂化C原子增多,涂层出现石墨化现象,这和涂层的颜色逐渐变深是一致的。

-

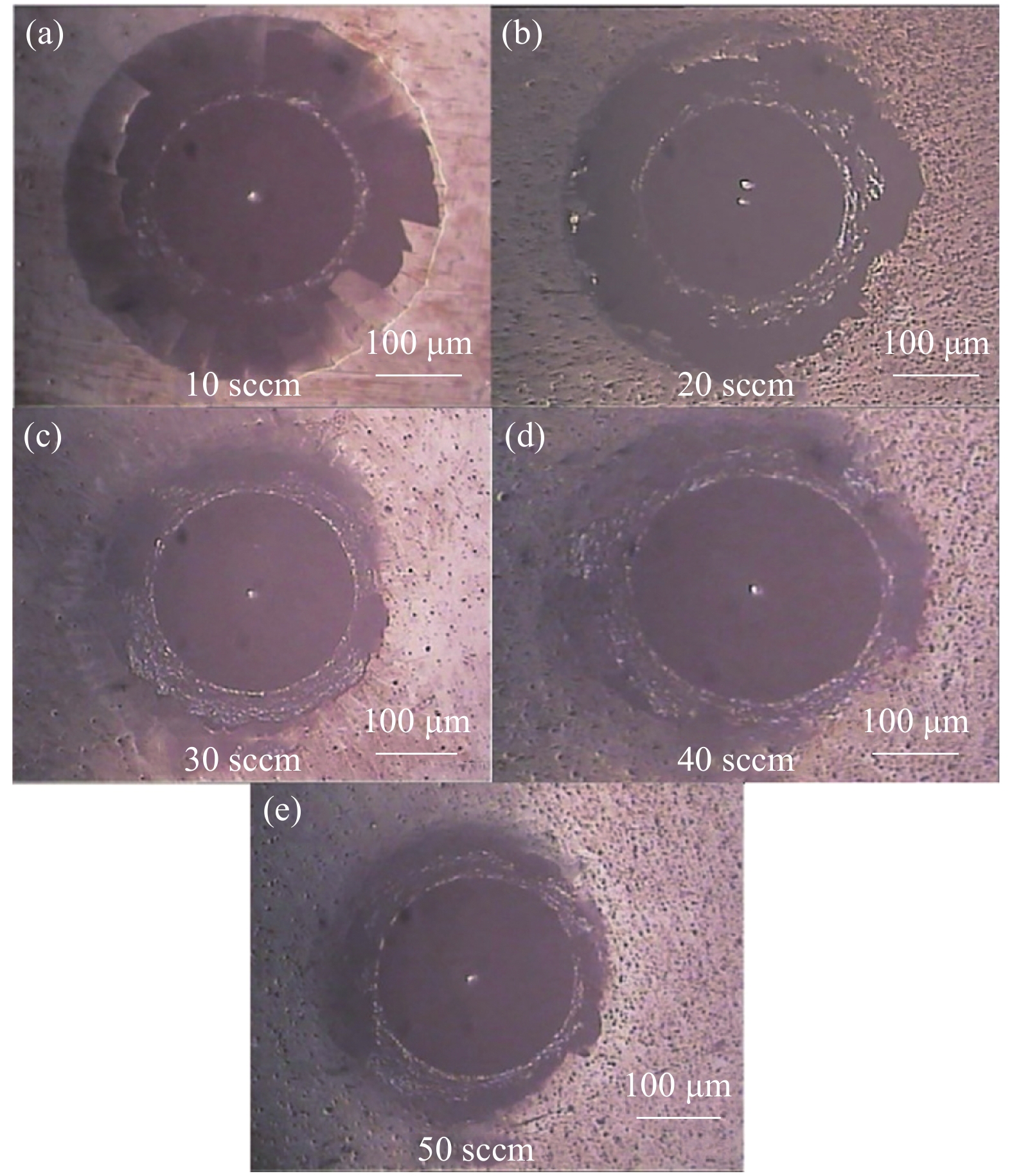

通过洛氏压痕法可以对比涂层的结合强度,在150 kg加载力下金刚石压头加载15 s卸载后得到的压痕形貌如图5所示。在低乙炔流量下,涂层中sp3含量较高,涂层应力较大;与无掺杂DLC涂层差异不大,随着C2H2流量的增加,压痕周围的涂层脱落减少,可判断涂层的压应力有一定的缓解,说明C2H2气体流量对 WC-DLC涂层与基体之间的结合力有着显著影响。

-

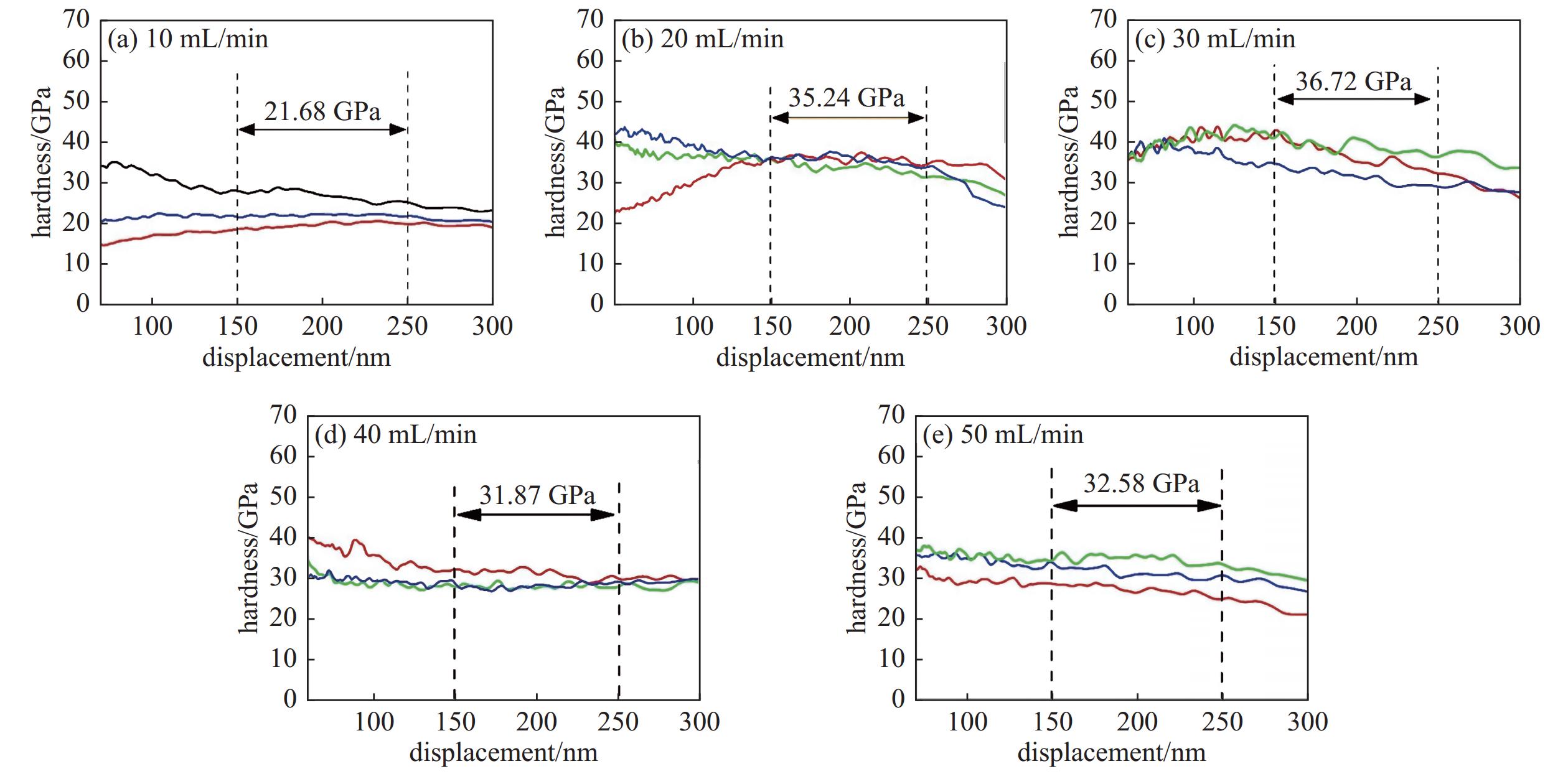

如图6所示,随着乙炔气体流量从10 mL/min增加到50 mL/min过程中,WC-DLC涂层纳米硬度分布为21.68 GPa,35.24 GPa,36.72 GPa,31.87 GPa,32.58 GPa,总体变化趋势是随着乙炔气体流量增加,呈先上升后下降的趋势,在30 mL/min时达到最大值。WC-DLC 的纳米硬度与涂层中sp3键相对含量密切相关,sp3-C越多,涂层的纳米硬度也就越高。C2H2流量为10 mL/min时,涂层中出现少量的sp3和sp2杂化碳原子,纳米硬度较低;当乙炔流量为20 mL/min和30 mL/min时,sp3键含量较高,涂层的硬度也随着升高,当C2H2流量增至40 mL/min和50 mL/min时,涂层表面的碳离子团增多,离子碰撞加剧,涂层中出现大量的非晶碳,sp2键含量增多,导致涂层纳米硬度出现一定的下降。

-

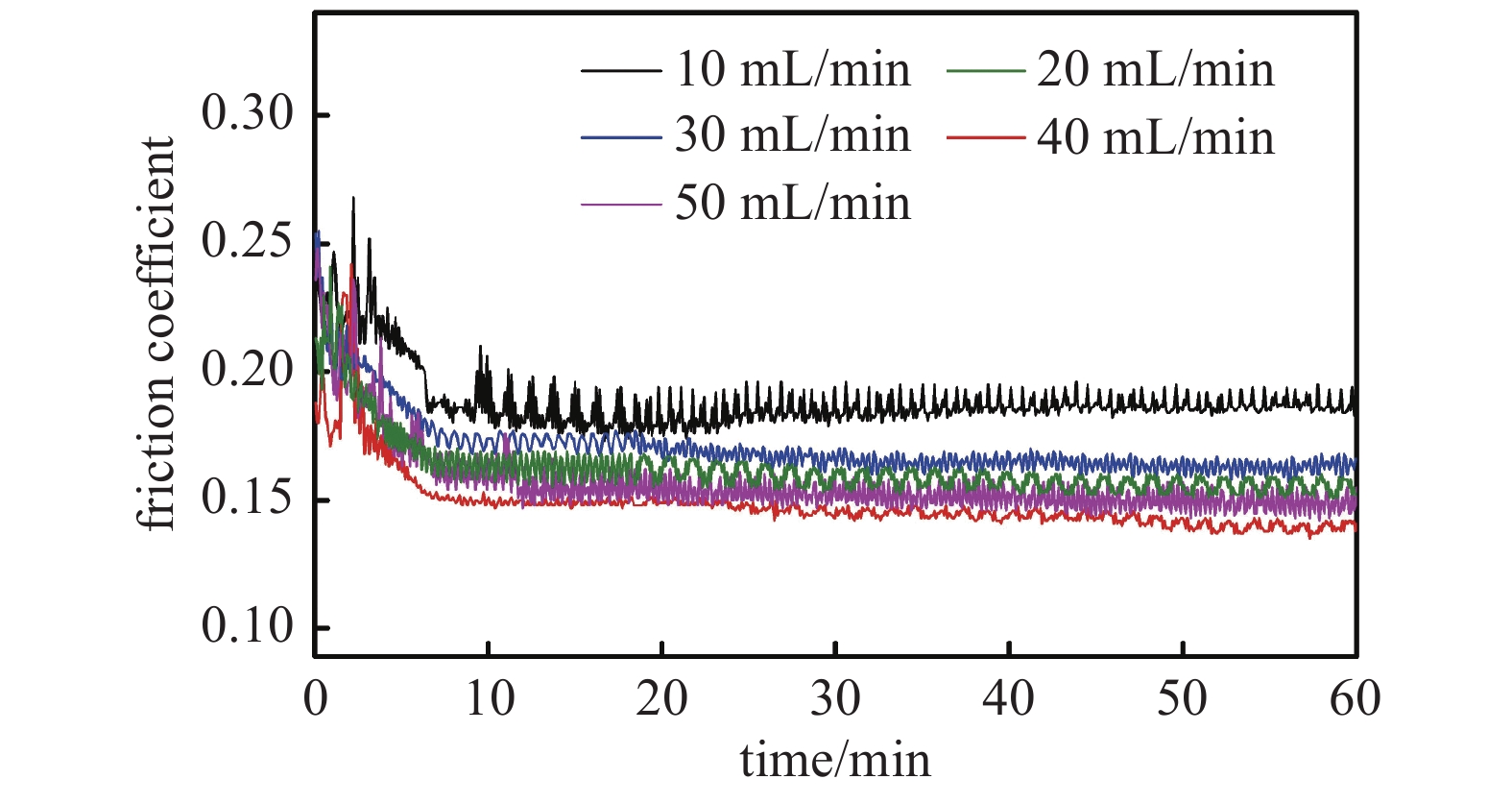

不同乙炔气体流量下沉积 WC-DLC 涂层的摩擦系数曲线分布如图7所示,在低C2H2流量时,涂层中碳原子含量较低,sp2和sp3杂化C原子相对较少,主要是WC1-x等晶相,晶粒尺寸大小不一,且涂层表面粗糙度较大,因此摩擦系数相对较高。随着乙炔流量增加,工件表面生成大量的石墨相C原子,特别是含有大量sp2杂化C原子的涂层具有润滑性,WC-DLC涂层的摩擦系数出现了明显的降低。摩擦系数的大小与工件表面的粗糙度以及涂层中的sp2含量紧密相关,乙炔流量增加,涂层的晶粒大小变得均匀,更加细化致密,粗糙度同时降低,使得WC-DLC涂层具有较低的摩擦系数。

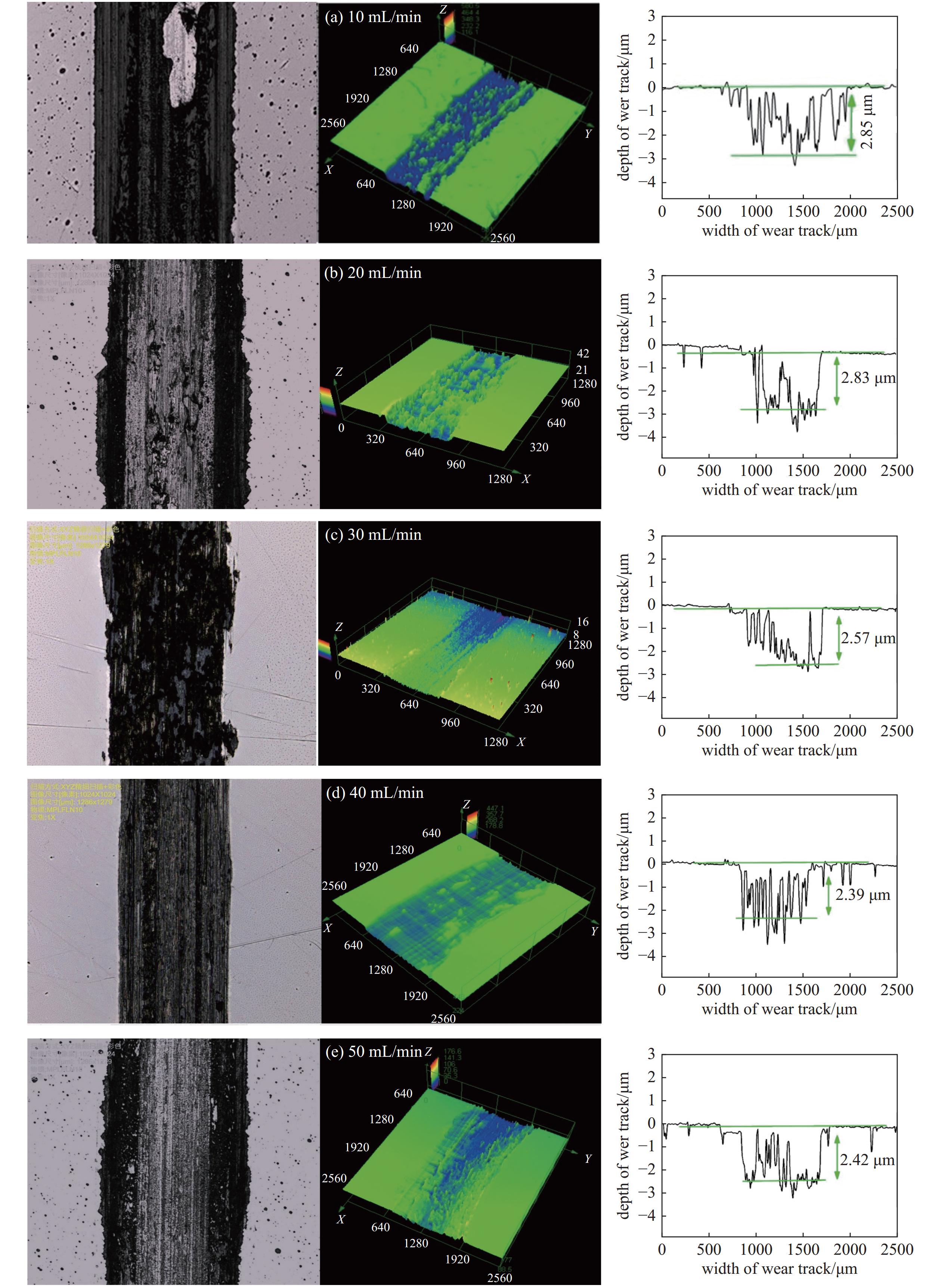

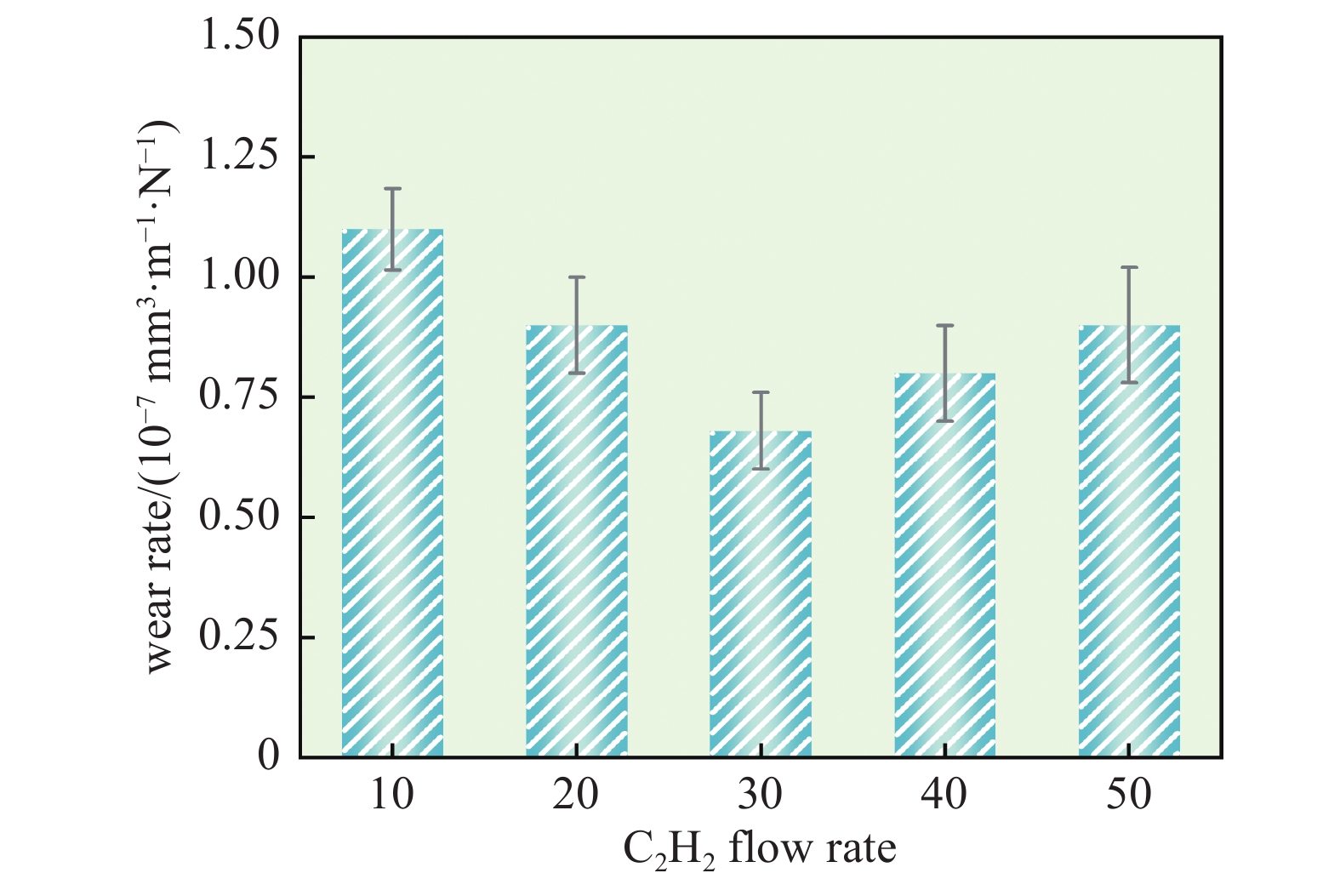

WC-DLC涂层结构不仅有利于提高其摩擦性能的稳定性,同时能减少在摩擦过程中出现剥落现象,避免了严重的磨粒磨损的现象,可在一定程度上提高涂层的抗磨损性能。图8和图9分别为不同乙炔流量制备的WC-DLC涂层的磨痕形貌、磨痕深度和磨损率。乙炔流量为10 mL/min时,涂层的磨损较严重,磨痕较宽;通过对比发现30 mL/min的涂层磨痕宽度窄,磨损量最小,这与涂层的纳米硬度、涂层中sp3相对含量密切相关。当乙炔为30 mL/min时,sp3含量较高,涂层的纳米硬度为36.73 GPa,保持相对较高的硬度对涂层的抗磨损性能具有重要的积极意义。当乙炔含量超过30 mL/min时,涂层中出现大量非晶碳相,sp2含量增加,sp3含量相对降低,涂层的纳米硬度和模量降低,磨痕变深,涂层的磨损量增加。

-

(1)WC-DLC涂层的制备过程中改变乙炔流量能够有效调控WC-DLC涂层的组分和微观结构,涂层中包含大量的非晶和纳米晶,粗糙度随着乙炔流量增加不断减小。

(2)随着乙炔流量的增加,涂层中C原子含量增加,涂层表面晶粒出现细化,晶粒尺寸减小,表现出细化和非晶化趋势,应力逐渐降低,涂层与基体结合力逐渐增强。

(3)随着乙炔流量的增加,WC-DLC涂层中石墨相不断增加,sp2和sp3含量比先升高后降低,涂层的纳米硬度也保持同样的变化趋势。在乙炔流量为30 mL/min时,WC-DLC 涂层的纳米硬度达到最大值36.72 GPa,同时涂层的磨痕深度和磨损率是最小,具有最佳的摩擦学性能。

C2H2气体流量对WC-DLC涂层结构与性能的影响

Effect of C2H2 Flow Rate on the Structure and Properties of WC-DLC Coatings

-

摘要: 文章采用直流磁控溅射技术制备WC-DLC耐磨涂层,为了探究C2H2流量对WC-DLC涂层表截面形貌、微观结构、力学和摩擦学性能的影响,在10−50 mL/min C2H2流量下制备了WC-DLC涂层并进行表征分析。结果表明,随着C2H2流量的增加,涂层中碳含量增加,晶粒逐渐细化,由柱状晶逐渐转变为细晶粒,涂层变得更加致密;涂层纳米硬度与sp3杂化的C原子含量密切相关,随着涂层中sp3-C含量的增加,硬度先升高然后降低,磨损率也先升高降低;随着碳原子含量升高,涂层中出现大量的非晶碳,表面晶粒非晶化,涂层的摩擦系数逐渐减小且更加稳定。Abstract: WC-DLC wear-resistant coatings were prepared by DC magnetron sputtering, and the influence of C2H2 gas flow rate on surface morphology, microstructure, mechanical and tribological properties of WC-DLC coatings prepared with a flow rate of C2H2 at 10−50 mL/min was investigated. Results show that, with the increasing flow rate of C2H2, the content of carbon in the coatings increases, the constituent of the coating gradually changes from columnar grain to fine grain, and the coating becomes denser. The nano-hardness of the coating is closely related to the content of hybridized sp3 carbon atoms. As the content of sp3-C in the coating increases, the hardness and wear rate of the coatings increase first and then decrease. When the carbon atom exceeds a certain content, a large amount of amorphous carbon will appear, the surface of the coating will become amorphous, and the friction coefficient gradually decreases and becomes more stable.

-

Key words:

- WC-DLC coating /

- Rate of flow /

- Nano-hardness /

- Bonding strength /

- Tribological properties .

-

-

表 1 涂层制备试验工艺参数

Table 1. Process parameters of the coatings

参数 涂层类别 Cr CrN WC-DLC 靶−基距/cm 9 9 9 温度/℃ 100 100 100 工作气体/Pa 0.6 0.7 1.2 氩气流量/(mL/min) 200 200 200 N2流量/(mL/min) — 40 — 乙炔流量/(mL/min) — — 10/20/30/40/50 靶电流/A 3 5 5 直流偏压/A 100 75 60 平均电压/V 224 335 365 沉积时间/min 3 30 60 表 2 不同C2H2流量下制备的 DLC 薄膜 Raman 高斯拟合结果

Table 2. Raman Gaussian fitting results of DLC films prepared at different C2H2 flow rates

不同乙炔气体

流量样品D peak G peak ID/IG Position

(cm−1)FWHM

(cm−1)Position

(cm−1)FWHM

(cm−1)10 mL/min 1358 357.7 1556 126.6 3.24 20 mL/min 1352 367.2 1554 128.3 2.71 30 mL/min 1356 363.9 1546 137.4 1.67 40 mL/min 1351 363.2 1557 127.2 2.23 50 mL/min 1357 357.7 1558 131.7 2.61 -

[1] Mayrhofer P H, Mitterer C, Hultman L, et al. Microstructural design of hard coatings[J]. Progress in Materials Science,2006,51:1032−1114 doi: 10.1016/j.pmatsci.2006.02.002 [2] Shen Y, Liao B, Zhang Z, et al. Anti-sand erosion and tribological performance of thick DLC coatings deposited by the filtered cathodic vacuum arc[J]. Applied Surface Science,2020,533:147371 doi: 10.1016/j.apsusc.2020.147371 [3] Cao H, Ye X, Li H, et al. Microstructure, mechanical and tribological properties of multilayer Ti-DLC thick films on Al alloys by filtered cathodic vacuum arc technology[J]. Materials & Design,2021,198:109320 [4] Zhang S, Yan M, Yang Y, et al. Excellent mechanical, tribological and anti-corrosive performance of novel Ti-DLC nanocomposite thin films prepared via magnetron sputtering method[J]. Carbon,2019,151:136−147 doi: 10.1016/j.carbon.2019.05.031 [5] Shiri S, Ashtijoo P, Odeshi A, et al. Evaluation of Stoney equation for determining the internal stress of DLC thin films using an optical profiler[J]. Surface & Coatings Technology, 2016, 98−100 [6] Chen K T, Chang J H, Wu J Y. Modified stoney's equation for evaluation of residual stresses on thin film[J]. Applied Mechanics & Materials,2015,789−790:25−32 [7] 郭有志, 孙丽丽, 郭鹏, 等. 自组织梯度分层结构金属掺杂类金刚石薄膜的制备及其性能研究[J]. 真空科学与技术学报,2018,38(9):764−771(in Chinese) Guo Y, Sun L, Guo P, et al. Preparation and properties of diamond-like films and doped with self-organized gradient layered structures[J]. Journal of Vacuum Science and Technology,2018,38(9):764−771 [8] Wu Y, Chen J, Li H, et al. Preparation and properties of Ag/DLC nanocomposite films fabricated by unbalanced magnetron sputtering[J]. Applied Surface Science,2013,284:165−170 doi: 10.1016/j.apsusc.2013.07.074 [9] Jiang X H, Zhou B, Piliptsou D G, et al. Structure and mechanical properties of (Cu, Ti) - binary metal doped diamond-like carbon films[J]. Advanced Materials Research,2011,150−151:217−222 [10] 林松盛, 代明江, 侯惠君, 等. 掺钛类金刚石膜的微观结构研究[J]. 真空科学与技术学报,2007,27(5):418−421(in Chinese) doi: 10.3969/j.issn.1672-7126.2007.05.012 Lin S, Dai M, Hou H, et al. Microstructure of Ti doped DLC films[J]. Journal of Vacuum Science and Technology,2007,27(5):418−421 doi: 10.3969/j.issn.1672-7126.2007.05.012 [11] Barriga J. Tribological performance of titanium doped and pure DLC coatings combined with a synthetic bio-lubricant[J]. Wear,2006,261:9−14 doi: 10.1016/j.wear.2005.09.004 [12] Kalin M, Roman E, Obolt L, et al. Metal-doped (Ti, WC) diamond-like-carbon coatings: Reactions with extreme-pressure oil additives under tribological and static conditions[J]. Thin Solid Films,2010,518:4336−4344 doi: 10.1016/j.tsf.2010.02.066 [13] Yao S H, Su Y L, Lai Y C. Antibacterial and tribological performance of carbonitride coatings doped with W, Ti, Zr, or Cr deposited on AISI 316L stainless steel[J]. Materials,2017,10:1189 doi: 10.3390/ma10101189 [14] Zahid R, Masjuki H H, Varman M, et al. Effect of lubricant formulations on the tribological performance of self-mated doped DLC contacts: a review[J]. Tribology Letters,2015,58:32 doi: 10.1007/s11249-015-0506-5 [15] Zahid R, Hassan M B H, Varman M, et al. A review on effects of lubricant formulations on tribological performance and boundary lubrication mechanisms of non-doped DLC/DLC contacts[J]. Critical Reviews in Solid State & Materials Sciences, 2017, 1-28 [16] Antunes R A, Lima N B D, Rizzutto M D A, et al. Surface interactions of a W-DLC-coated biomedical AISI 316L stainless steel in physiological solution[J]. Journal of Materials Science Materials in Medicine,2013,24:863−876 doi: 10.1007/s10856-013-4871-z [17] 王翔, 代明江, 戴达煌, 等. WC/DLC纳米多层膜微观结构研究[J]. 真空科学与技术学报, 2013, 41−44(in Chinese) Wang X, Dai M, Dai D, et al. Study on microstructure of WC/DLC nano multilayers[J]Journal of Vacuum Science and Technology, 2013, 33(1): 41−44 [18] Guo T, Kong C, Li X, et al. Microstructure and mechanical properties of Ti/Al co-doped DLC films: Dependence on sputtering current, source gas, and substrate bias[J]. Applied Surface Science,2017,410:51−59 doi: 10.1016/j.apsusc.2017.02.254 [19] Bobzin K, Brögelmann T, Stahl K, et al. Friction reduction of highly-loaded rolling-sliding contacts by surface modifications under elasto-hydrodynamic lubrication[J]. Wear,2015,328−329:217−228 doi: 10.1016/j.wear.2015.02.033 [20] Mistry K K, Morina A, Neville A. A tribochemical evaluation of a WC–DLC coating in EP lubrication conditions[J]. Wear,2011,271:1739−1744 doi: 10.1016/j.wear.2011.01.071 [21] Nemati N, Penkov O V, Kim D E. Superior surface protection governed by optimized interface characteristics in WC/DLC multilayer coating[J]. Surface and Coatings Technology,2020,385:125446 doi: 10.1016/j.surfcoat.2020.125446 [22] Dai W, Kwon S H, Wang Q, et al. Influence of frequency and C2H2 flow on growth properties of diamond-like carbon coatings with AlCrSi co-doping deposited using a reactive high power impulse magnetron sputtering[J]. Thin Solid Films,2018,647:26−32 doi: 10.1016/j.tsf.2017.12.016 [23] Tillmann W, Ulitzka H, Lopes Dias N F, et al. Effects of acetylene flow rate and bias voltage on the structural and tribo-mechanical properties of sputtered a-C: H films[J]. Thin Solid Films,2020,693:137691 doi: 10.1016/j.tsf.2019.137691 [24] Fu Z Q, Wang C B, Zhang W, et al. Influence of W content on tribological performance of W-doped diamond-like carbon coatings under dry friction and polyalpha olefin lubrication conditions[J]. Materials & Design,2013,51:775−779 [25] Huang K, Li H, Luo Y, et al. An effort towards hard and tough coatings by cathodic arc deposition of Zr-Cr-O coating system[J]. Surface and Coatings Technology,2020,400:126177 doi: 10.1016/j.surfcoat.2020.126177 -

首页

首页 登录

登录 注册

注册

下载:

下载: