-

为满足实际工程要求,某在役5000 m3风洞用真空球罐需新增一个DN1000孔。风洞在航天航空工程发展中起着关键作用[1-2],大型真空球罐作为风洞的重要组成部分,用于为飞行器开展地面试验研究提供真空保障,其安全性能对风洞试验的顺利完成十分重要[3-4]。焊后热处理工艺的验证[5-7]、球罐强度和疲劳寿命分析[8-9]、屈曲稳定性分析[10-11]是球罐安全性能鉴定过程中主要关注的方面。而如何对大型球罐开孔后进行补强,以保证其安全性能是球罐设计中的难点之一[12-14]。李欣欣等[15]提出了一种整体补强锻件结构;徐永生等[16]研究了不同接管厚度、开孔直径、开孔数量和位置对真空球罐抗失稳能力的影响;吴晓红[17]、任金平[18]等利用加强肋对10000 m3真空球罐进行了补强。综上,补强圈、引出管和加强肋是常用的真空球罐开孔补强方式,但不同补强方式在强度、寿命和刚度等方面补强效果的差异性还不清晰。此外,目前关于超大容积风洞球罐的安全鉴定均是针对于设计阶段,而关于在服役中风洞球罐上新增开孔后其安全性能衰减程度的相关研究还鲜有报道。

有限元法是分析薄壳结构稳定性的有效手段[19]。本文利用有限元法对某在役5000 m3风洞真空球罐的强度、疲劳和刚度性能进行了细致的分析,讨论了不同开孔方案下球罐安全性能的差异性。研究成果将为服役中真空球罐新增开孔后补强方案的制定提供理论支撑。

-

某风洞在役5000 m3真空球罐设计壁厚为30 mm,主体材料为Q345R,球罐由12个支柱支撑,支柱之间通过钢筋交叉连接固定。该球罐作为风洞试验系统中的气源,试验过程中主要负载为自重和大气压,每天平均循环20次,每年平均计300天,设计寿命50年,设计循环寿命为3.0×105次。罐体上除去上下极孔外,还分布着两个DN3000和两个DN2000大直径孔。

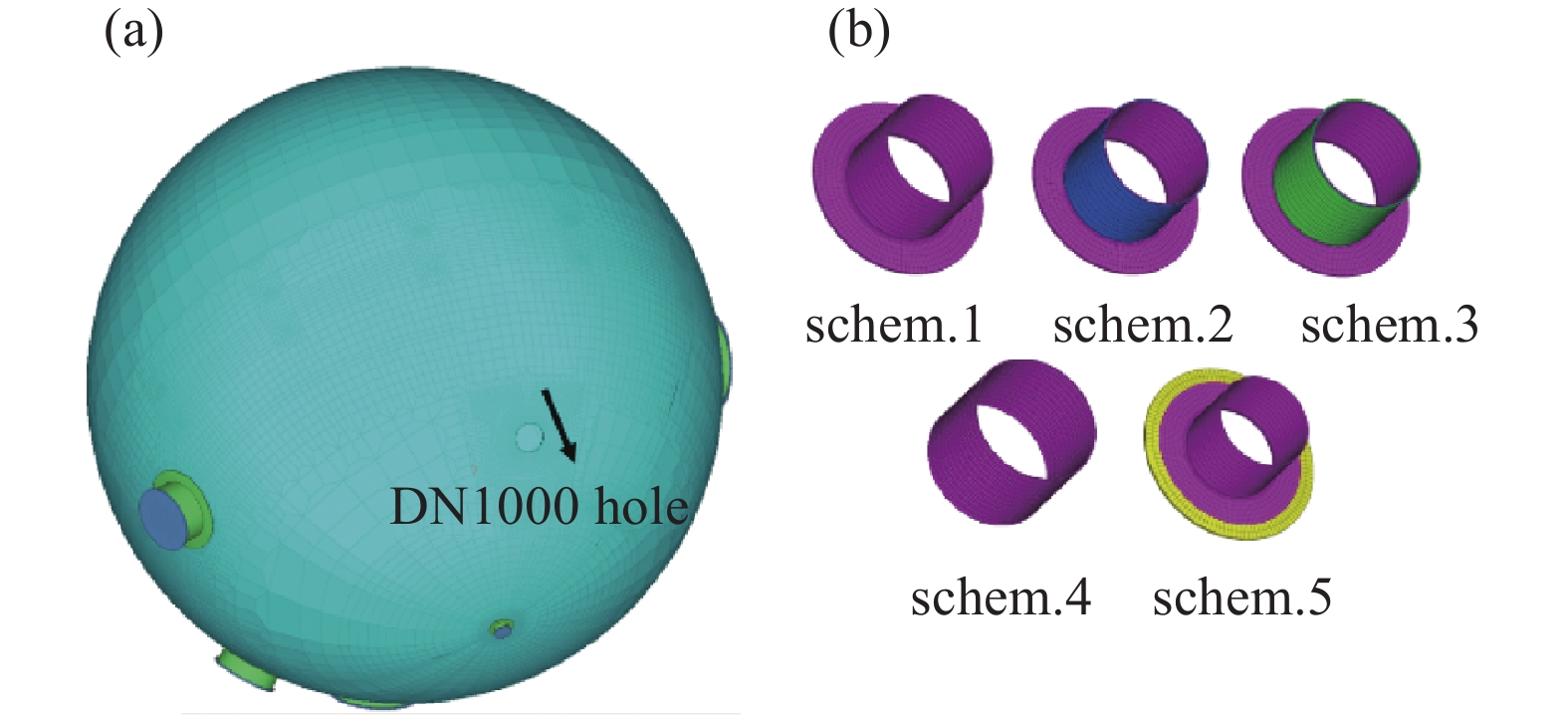

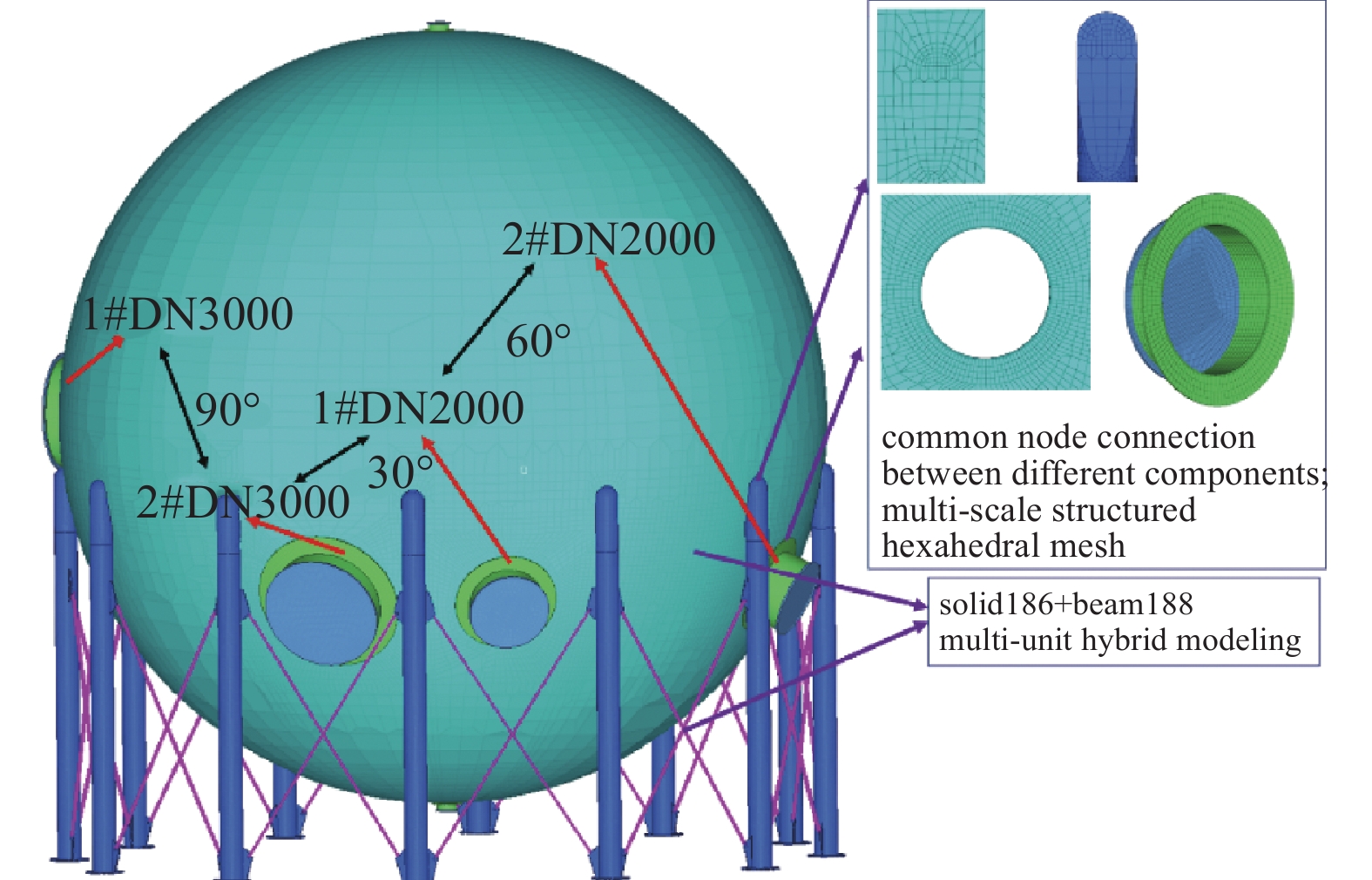

由于风洞球罐容积大,且为多开孔不规则结构,其性能鉴定一般通过有限元法完成。考虑风洞试验的特殊性,球罐安全性能的有限元分析结果应尽可能的精准可靠。采用Hypermesh结合Apdl的方式对该真空球罐展开分析。基于Hypermesh对球罐进行手动控制的结构化六面体网格划分,经检验网格质量在长宽比、翘曲度、偏斜度和内角四个方面均满足GB/T 33582-2017 《机械产品结构有限元力学分析通用规则》的要求。网格划分结果如图1所示。

观察图1,该球罐由球体、开孔补强圈、开孔引出管、盲盖、支座和支座钢筋组成。球罐模型采用solid186和beam188多单元耦合建模,各零部件相贯面网格完全映射,采用共节点的形式实现开孔补强圈、开孔引出管、盲盖、支座和球体之间的载荷传递,最大程度的消除了网格误差对计算结果的影响。为了便于讨论,将球体上的开孔从左到右依次编号为:1#DN3000、2#DN3000、1#DN2000、2#DN2000,图中相邻两孔之间的黑色双箭头表示开孔圆心与球心连线的夹角。

由于工程实践需要,在球罐上需要新增一个DN1000的圆孔,新开孔位置及预设的补强方案如图2所示。图2中新开DN1000孔与2#DN2000、1#DN3000夹角为90°,与1#DN2000夹角为120°,与2#DN3000夹角为180°。为了对新开孔进行补强,设计了5种补强方案,彼此之间区别在于引出管壁厚和补强圈宽度。各方案详情如表1所示。

-

本节对开孔前后球罐的强度与寿命性能进行评估对比,阐明新增开孔对球罐强度与寿命的影响,讨论不同补强方案补强效果的差异性。分析过程中球罐整体模型保持不变,不同分析对象之间的区别仅在于是否存在DN1000孔及其补强组件的变化,保证了计算结果的可比性。

-

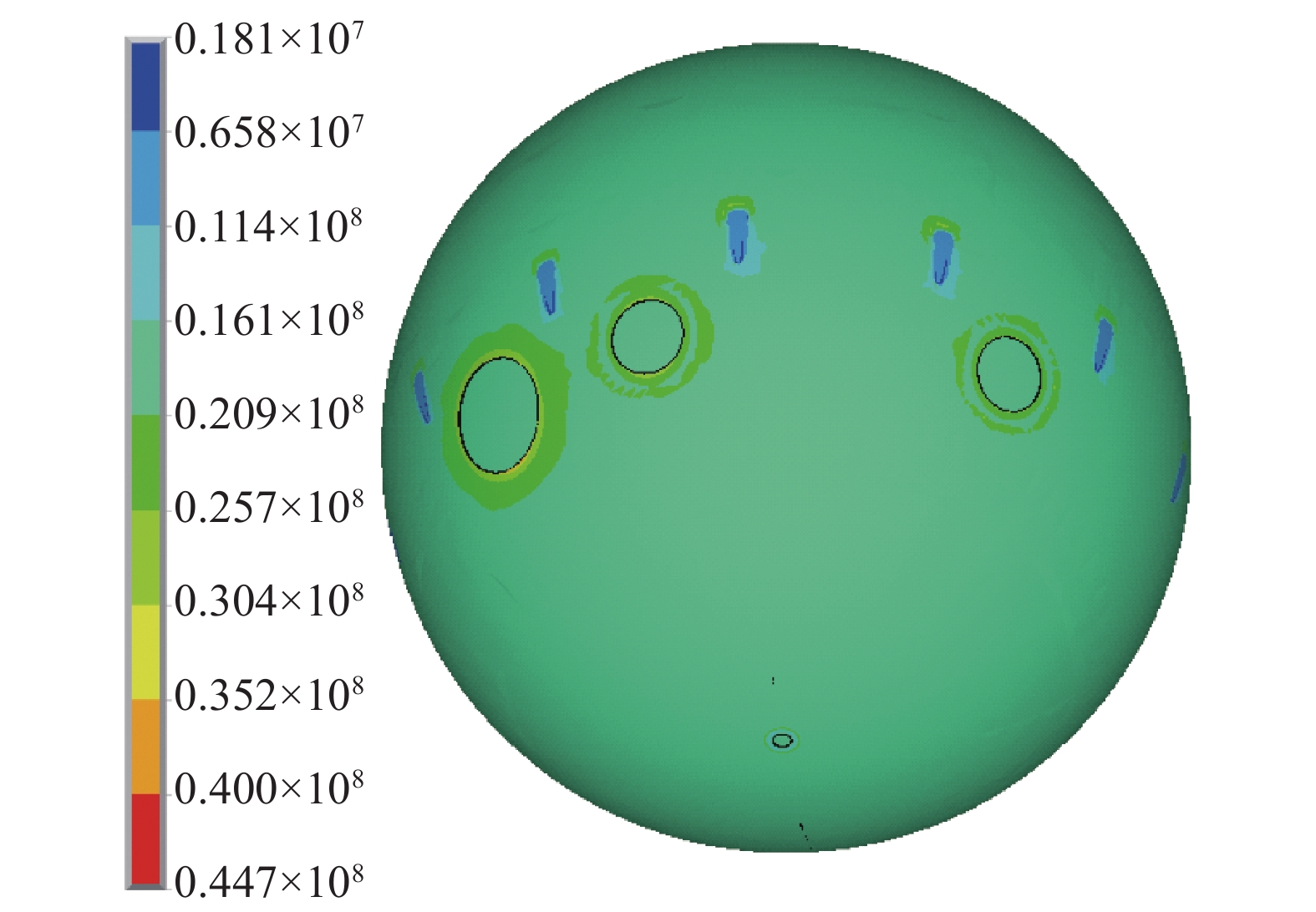

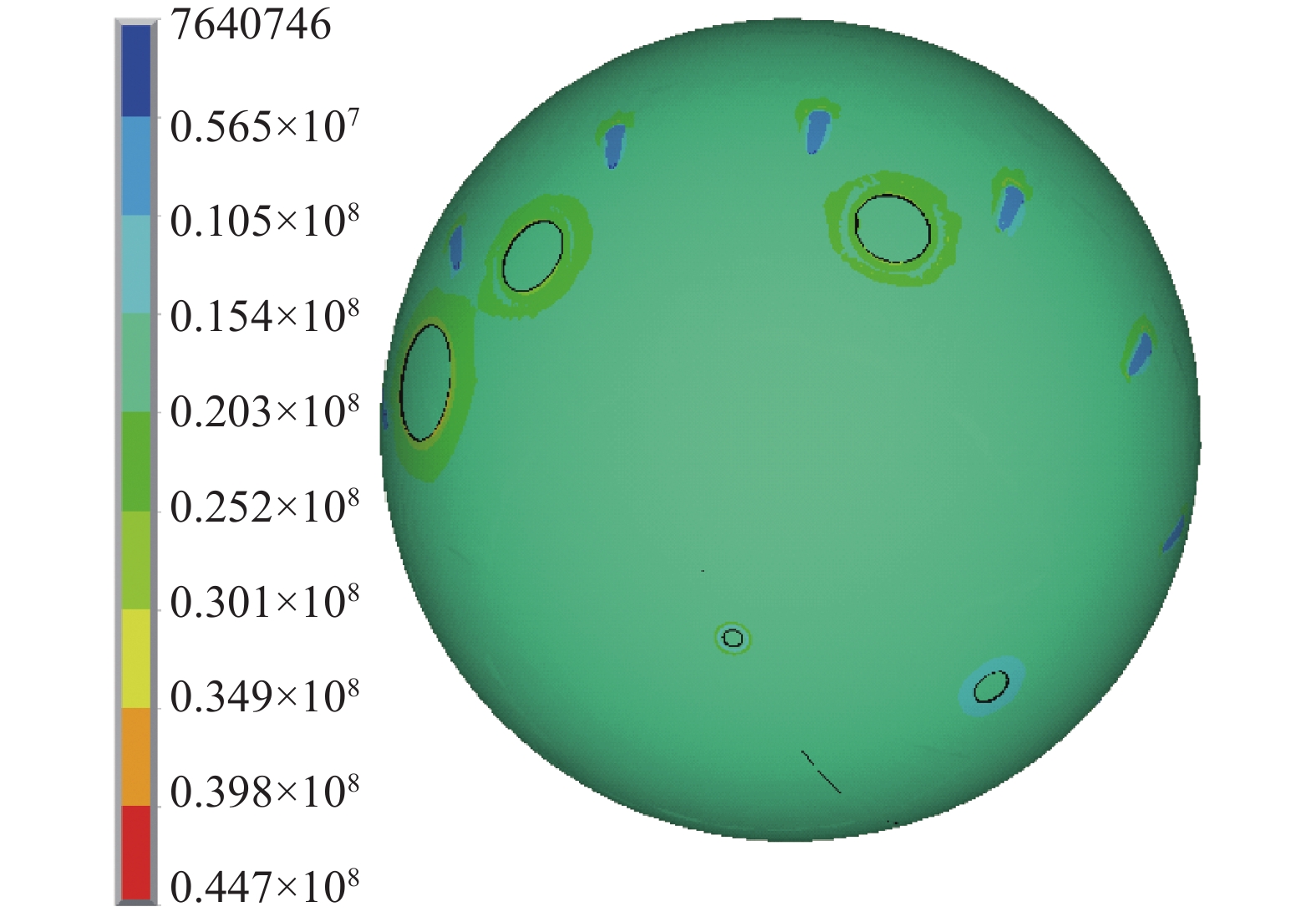

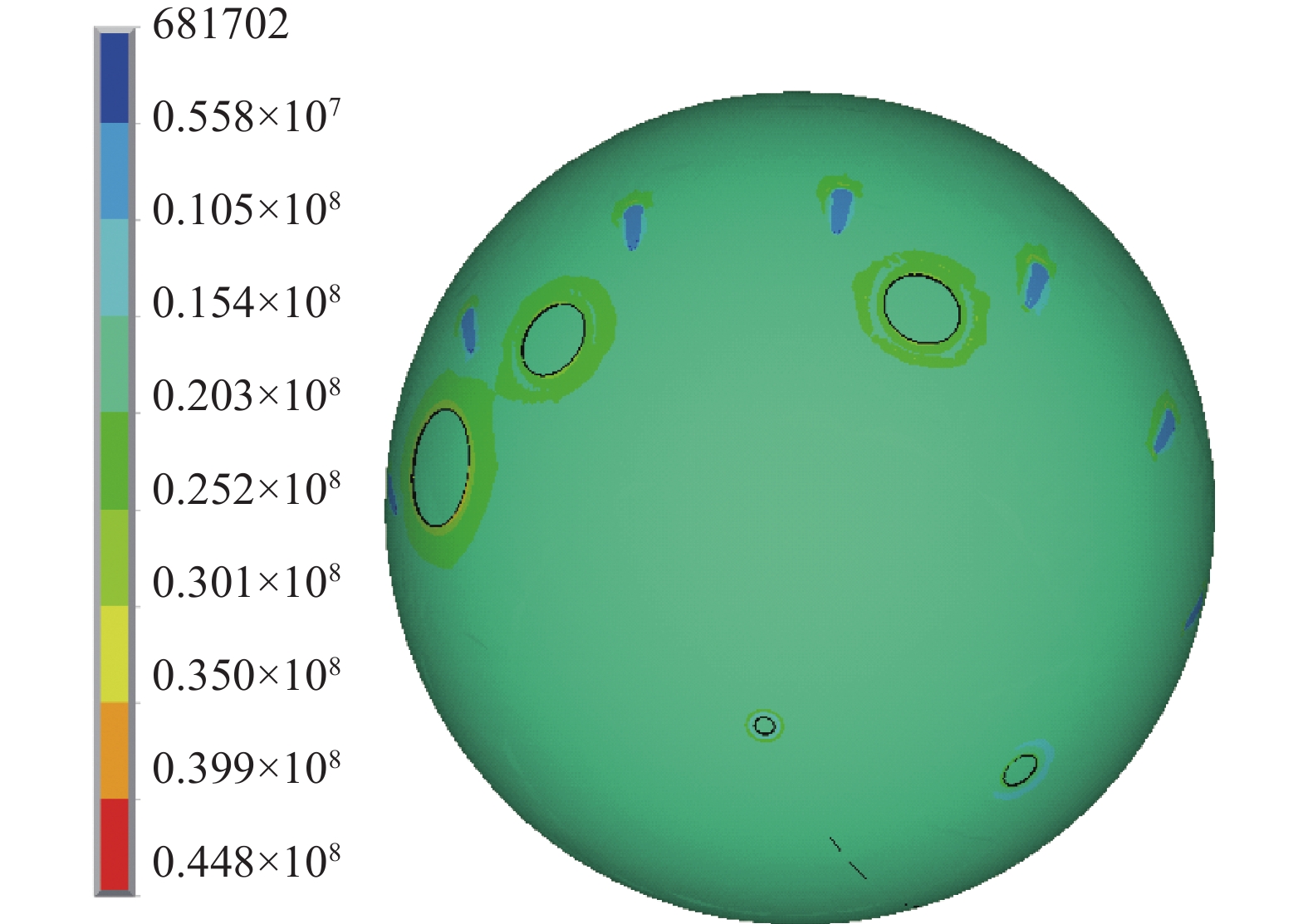

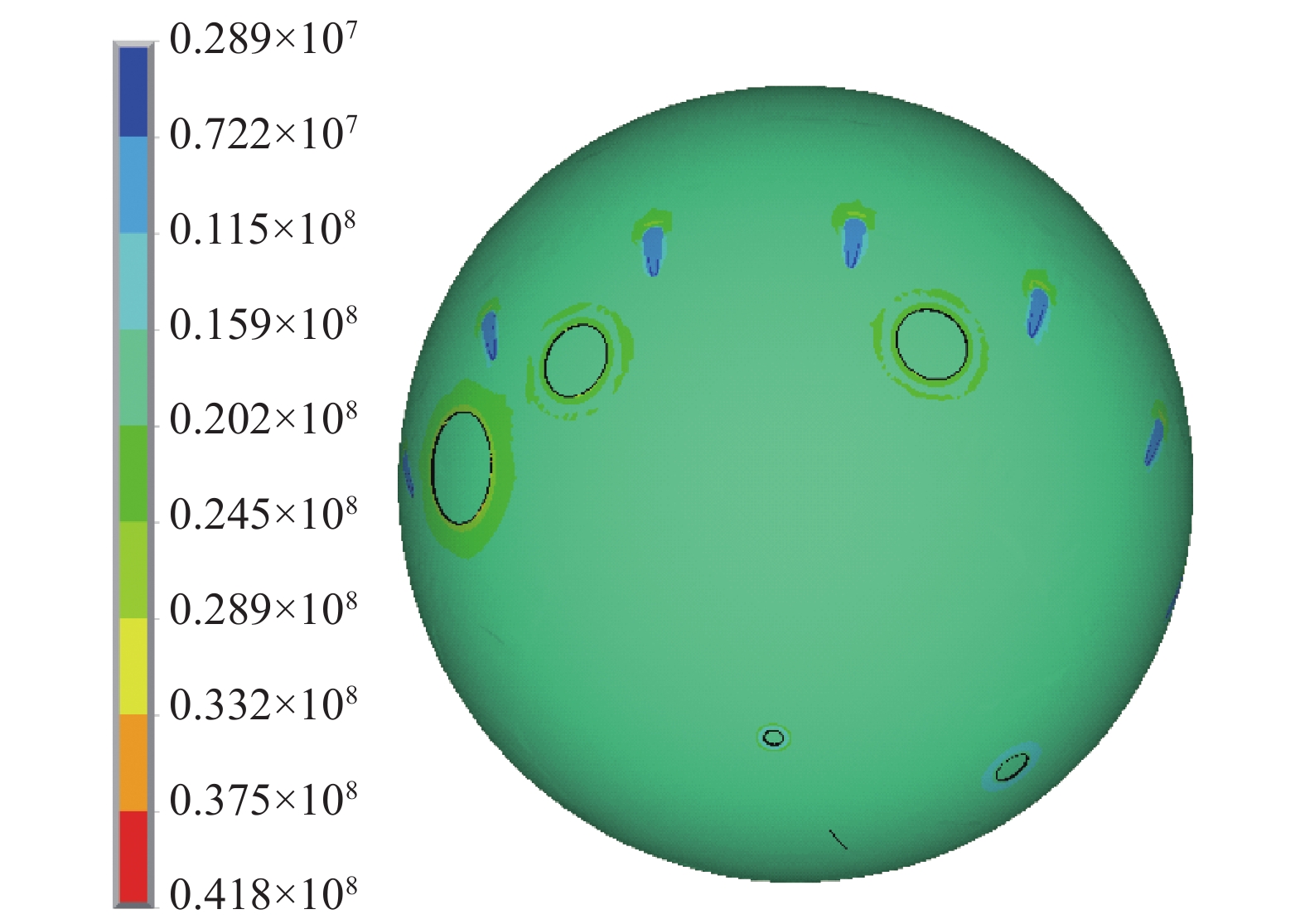

约束球罐支座底部节点的所有方向的自由度,施加自重和外压载荷后,对新增开孔前后的球罐进行强度分析。未开孔前球罐球体应力分布如图3所示,采用方案1、2、3开孔后罐体应力分布如图4所示,采用方案4、5开孔后罐体应力分布如图5、6所示。

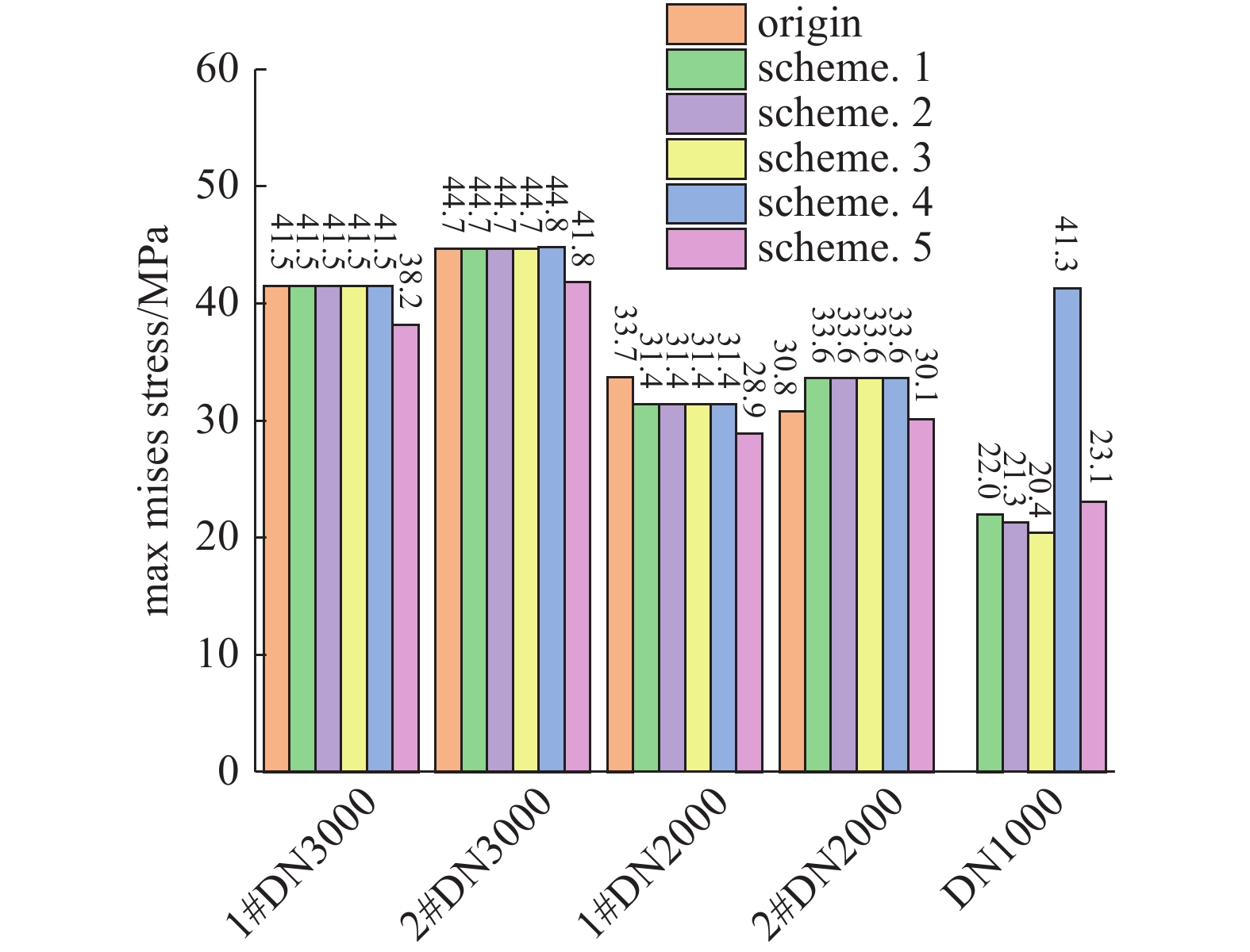

观察图3至图6,开孔后无论采用那种方案进行补强,球体整体应力分布趋势基本相同。对比图3和图4,补强圈宽度为300 mm时,增加引出管壁厚对球体整体应力分布无影响,球体应力峰值均为44.7 MPa。当不设置补强圈时,球体应力峰值增加至44.8 MPa,补强圈宽度增加至460 mm时,球体应力峰值降低至41.8 MPa,甚至低于初始球体峰值应力。为进一步讨论不同方案下球罐强度差异,将不同开孔部位局部应力峰值绘制于图7。

先讨论新增开孔对球罐原有开孔的影响。观察图7,对两个DN3000孔,新增DN1000开孔后,对其局部峰值应力影响较小。改变引出管壁厚(方案1至3)或者不设置补强圈(方案4)对其局部峰值应力几乎没有影响,而将补强圈宽度增加至460 mm时(方案5),1#DN3000、2#DN3000峰值应力分别下降了7.9%、6.2%。

对于1#DN2000,新增开孔反而降低了其局部峰值应力。而加宽补强圈后,其应力降低14.2%。

对于2#DN2000,新增开孔后其局部峰值应力增加9.1%。改变新增开孔处引出管壁厚或者不设置补强圈同样对2#DN2000局部峰值应力无影响,然而增加补强圈宽度后,新增开孔对2#DN2000局部峰值应力影响得以缓解,相对于开孔前甚至降低了2.2%。

接下来讨论不同补强方案对新增DN1000开孔局部应力峰值影响。观察图7,随着引出管壁厚增加,以方案1壁厚为10 mm结果为基准,当壁厚为20 mm和30 mm时,DN1000孔局部峰值应力分别降低3.2%和4.2%。当不设置补强圈时,DN1000孔局部峰值应力大幅增加,增加幅度达87.7%,增加补强圈宽度时,DN1000孔局部峰值应力反而小幅增加5%。

综上,新增开孔对原有开孔局部应力分布影响均在10%以内,开孔后球罐强度依然符合要求。对于不同补强方案而言,增加引出管壁厚只影响新开孔位置的局部应力分布,补强圈的设置是必要的,但补强圈宽度不宜过宽。

-

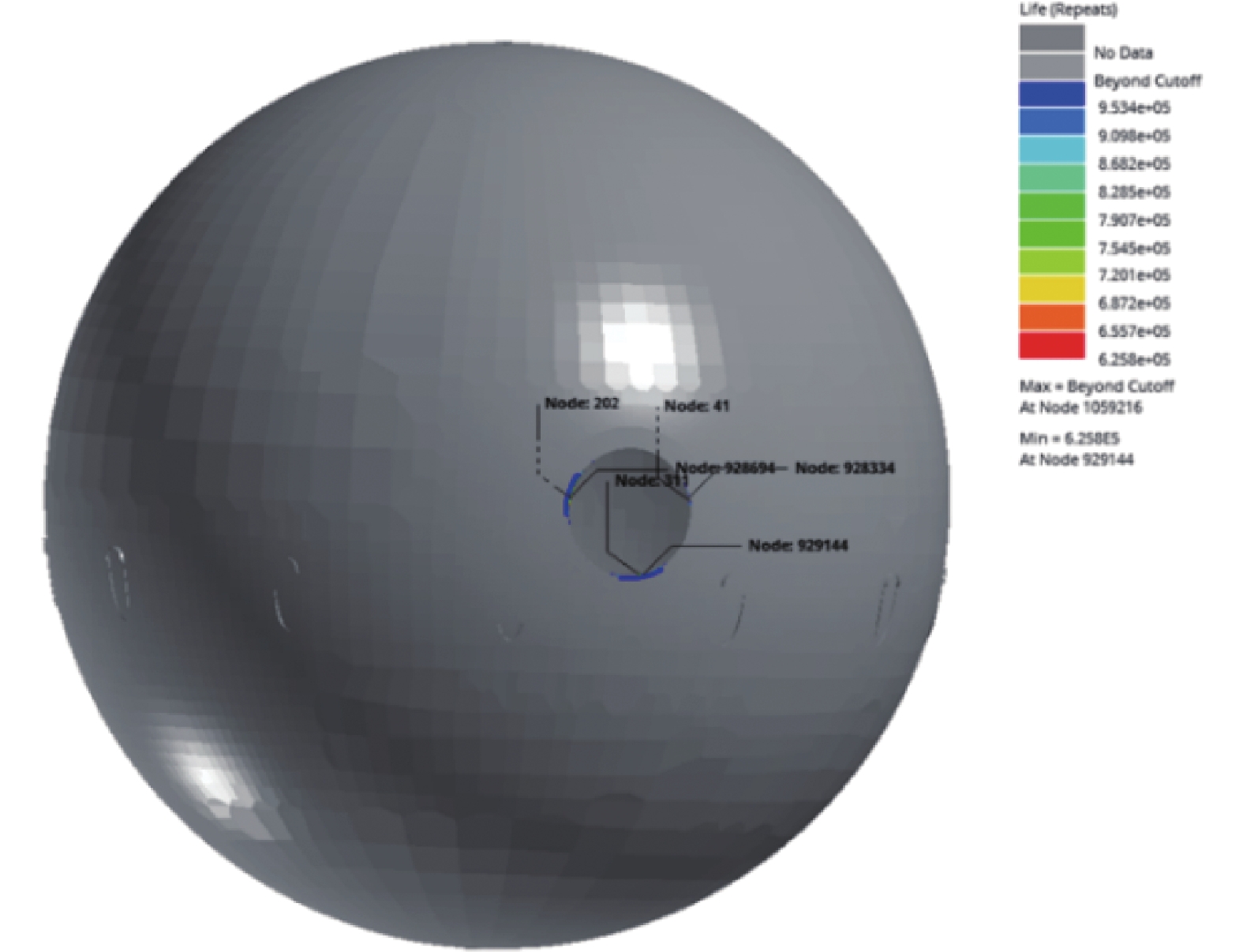

本节对新增开孔后5000 m3真空球罐循环寿命的差异性进行研究。球罐应力循环来源于压力波动,将2.1中球罐应力计算结果导入Ncode软件,以恒定幅值的方式进行载荷映射,通过FKM模型修正平均应力,基于材料的S-N曲线对不同球罐模型的寿命进行计算。球罐球体初始寿命计算结果如图8所示。

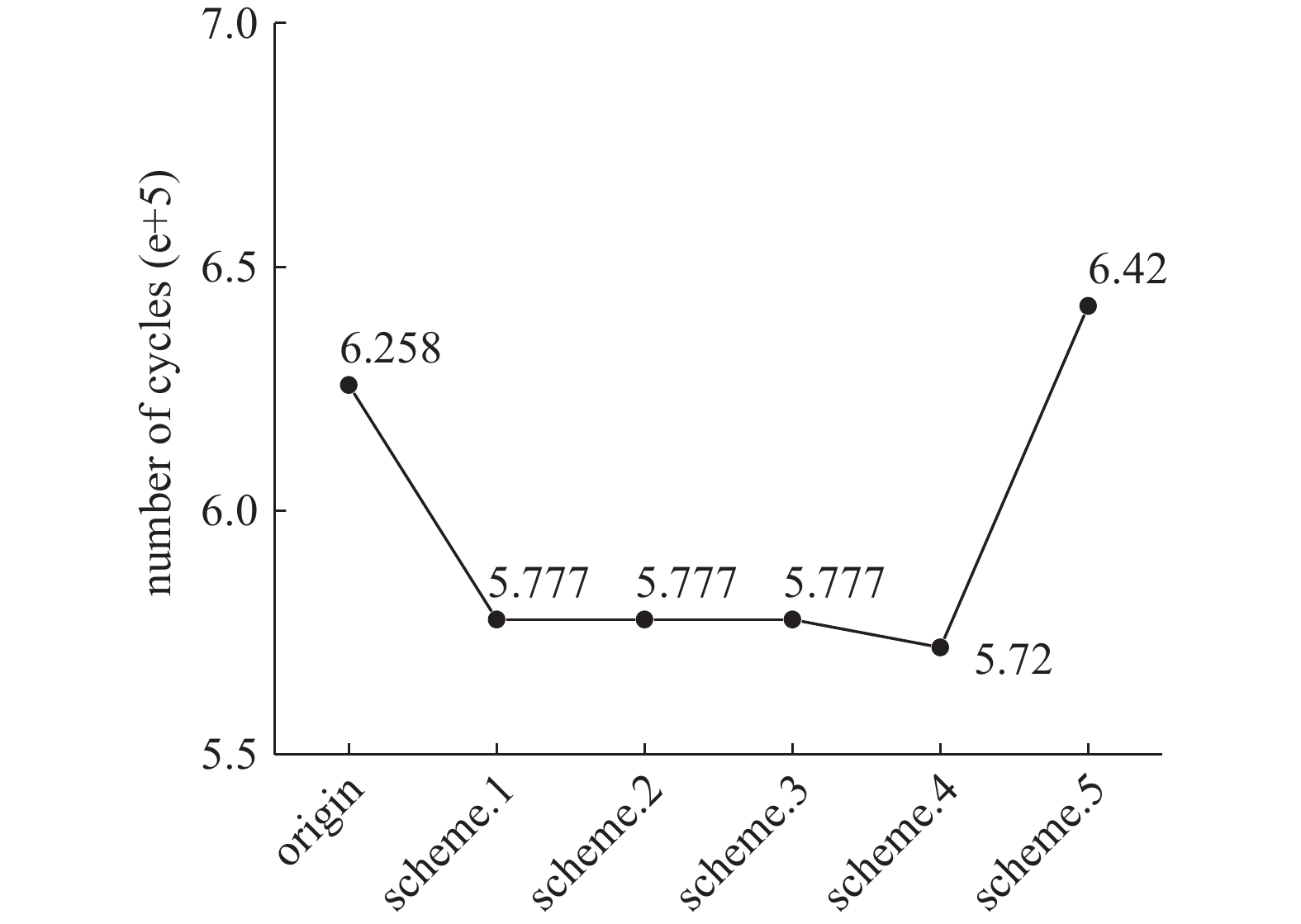

由图8可知,球罐球体疲劳损伤首先出现在1#DN3000开孔边缘部位,最小循环次数为6.258×105次。依方案1至方案5开孔后,球罐球体疲劳损伤部位并没有发生改变,但不同方案下最小循环次数不同,如图9所示。

由图9可知,新增开孔后,球罐寿命依然满足设计要求,但除方案5外,其他开孔方案均会导致球罐循环寿命降低。具体而言,增加引出管壁厚只影响新开孔局部位置的峰值应力,对开孔后球罐循环寿命无影响,相对于初始循环寿命,采用方案1至3时,开孔后球罐循环寿命降低7.6%,若不设置补强圈,其循环寿命将降低7.8%。开孔后若增加补强圈宽度,相对于初始循环寿命,开孔后反而增加2.5%。即增加补强圈宽度随对新开孔局部位置应力改善作用小于增加引出管壁厚,但能够大幅提升开孔后球罐的最小循环寿命。

-

屈曲失稳是真空球罐的主要失效模式,5000 m3真空球罐为多开孔结构,新增开孔后其刚度将进一步降低,本节对原始球罐及不同方案开孔后的球罐进行屈曲分析,校核不同球罐模型的抗失稳能力。

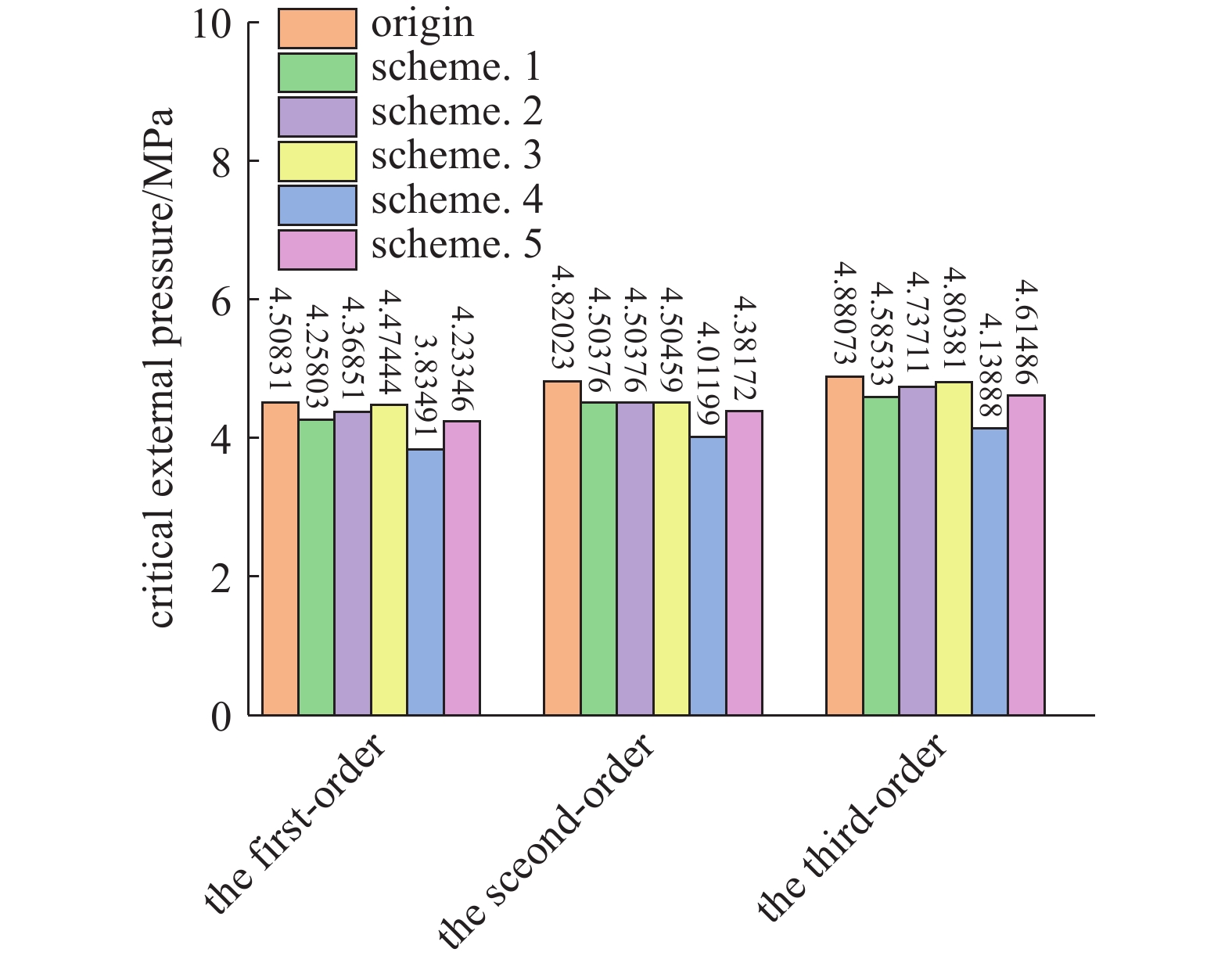

球罐临界外压等于屈曲特征值和承受外压的乘积,除以规定的安全系数后即可得到球罐的许用外压,其详细计算过程在文献[8]中有详细叙述。本文选择以临界外压为参数,研究不同模型抗失稳能力的差异性。原始球罐及不同开孔方案后球罐的前三阶临界外压如图10所示。

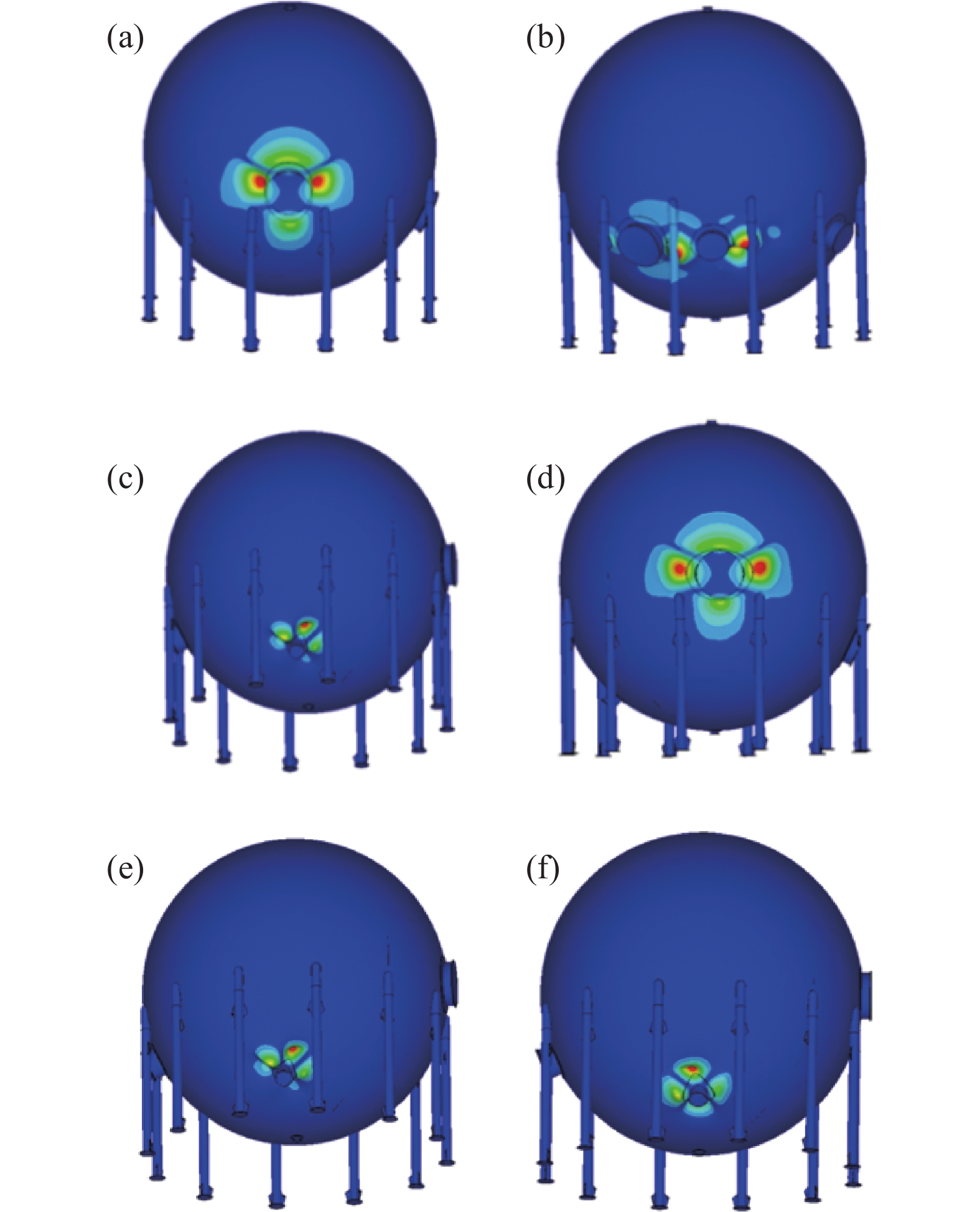

由图10可知,新增开孔后,无论采用何种补强方案,球罐刚度均会小幅降低。固定补强圈宽度,增加引出管壁厚,各阶临界外压值均小幅增加;若不采用补强圈,球罐第一阶临界外压将降低14.9%,加强圈宽度过宽反而会导致各阶临界外压降低。不同方案下球罐屈曲模态分布如图11所示。

由图11可知,初始球罐前两阶失稳表现为1#DN3000孔局部区域的凹陷和2#DN3000、1#DN2000开孔位置大片的凹陷。新增DN1000开孔后,不同开孔方案下第一阶失稳均表现为新开孔部位的凹陷,区别在于第二阶模态分布。

方案1至方案3,其第二阶屈曲模态分布与开孔前第一阶类似,而方案4、5第二阶屈曲模态分布依然表现为DN1000开孔部位的凹陷。综上,为了弥补新开孔后球罐的刚度损失,引出管和补强圈应同时设置,引出管壁厚增加对刚度补强效果更为明显,论文[7]结论也证明了这一点,然而对补强圈宽度增加应慎重,因为补强圈宽度与球罐刚度的关系并非单调。

-

为验证某在役5000 m3真空球罐是否满足新开DN1000孔的条件,利用有限元法研究了开孔前后球罐强度、循环寿命和刚度性能的差异性,对比了不同补强方案的补强效果,得到以下结论:

(1)强度方面,新增DN1000孔对球罐整体应力分布趋势和原有开孔位置局部应力峰值影响程度有限,引出管补强能有效降低DN1000孔位置的局部峰值应力,对其他开孔位置无影响,而补强圈对DN1000孔位置的局部峰值应力影响程度较小,但对其他原有孔局部位置的应力峰值有改善效果;

(2)循环寿命方面,新增开孔前后疲劳损伤均率先出现在1#DN3000开孔边缘部位,增加引出管壁厚球罐寿命几乎没有影响,而增加补强圈宽度能有效增加球罐循环寿命,甚至超过开孔前状态;

(3)刚度方面,新增开孔后球罐屈曲失稳首先出现在新开孔部位,增加引出管壁厚对刚度补强效果明显,而增加补强圈宽度反而会导致球罐刚度的轻微下降;

(4)理论证明,某在役5000 m3真空球罐基本满足新开DN1000孔的条件,应综合使用引出管和补强圈两种方式进行补强;

论文研究成果为某在役5000 m3真空球罐新增DN1000开孔后的安全使用和补强方案的选择提供了理论支撑,但分析过程并未考虑该球罐服役过程的性能衰减,最终新增开孔方案应在对球罐现场检验后确定。

5000 m3真空球罐新开DN1000孔后安全性能差异性研究

The Safety Performance Difference of 5000 m3 Vacuum Spherical Tank after Adding DN1000 Hole

-

摘要: 某在役风洞5000 m3真空球罐需要新增一个DN1000孔,对新增开孔前后球罐强度、刚度和差异性展开研究,对比各类补强方案的补强效果,得到以下结论:新增开孔将降低球罐整体的刚度和使用寿命,但影响程度有限。增加新开孔的引出管壁厚对球罐整体刚度补强效果明显,只降低自身开孔处的应力峰值;补强圈能够有效降低开孔后原有其他孔部位的应力峰值,对新增开孔后球罐使用寿命有明显的提升,但新开孔部位的局部应力、球罐刚度与补强圈宽度的关系是非单调的,补强圈宽度不宜过宽。研究成果证明某在役风洞5000 m3真空球罐新增DN1000开孔后其性能依然满足设计要求,同时为超大容积真空球罐补强方案的制定提供了理论支撑。Abstract: An in-service wind tunnel vacuum spherical tank needs to add a DN1000 hole. The differences in strength, stiffness, and life of the spherical tank before and after adding holes were studied, and the reinforcing effects of various reinforcing schemes were compared. The following conclusions are obtained: additional holes will reduce the overall stiffness and service life of the spherical tank, but the impact is limited. Increasing the wall thickness of the hole outlet pipe has an obvious reinforcement effect on the overall stiffness and only reduces the stress peak at the opening point. The reinforcing ring can effectively reduce the stress peak of other parts of the original hole, and significantly improve the service life of the spherical tank after the newly opened hole. However, the relationship between the local stress of the newly opened part, the stiffness of the spherical tank and the width of the reinforcing ring is non-monotonic; the width of the reinforcing ring should not be too wide. The research results prove that the performance of the vacuum spherical tank still meets the design requirements after adding DN1000 hole, and provide theoretical support for the formulation of the super-large volume vacuum spherical tank reinforcement scheme.

-

Key words:

- Wind tunnel /

- Vacuum spherical tank /

- Opening reinforcement /

- Finite element analysis .

-

-

图 11 不同球罐模型屈曲模态分布。(a)初始模型第一阶;(b)初始模型第二阶;(c)方案1/2/3第一阶;(d)方案1/2/3第二阶;(e)方案4/5第一阶;(f)方案4/5第二阶

Figure 11. Buckling mode distribution of different spherical tank models. (a) Initial model first order, (b) initial model second order, (c) No. 1 / 2 / 3 first order, (d) No. 1 / 2 / 3 second order, (e) No. 4 / 5 first order, (f) No. 4 / 5 second order

表 1 新开DN1000孔补强方案

Table 1. Reinforcement schemes for newly opened DN1000 hole

方案1 方案2 方案3 方案4 方案5 引出管壁厚/mm 10 20 30 10 10 补强圈宽度/mm 300 300 300 0 460 -

[1] Hou Fengwei,Zhang Donglin,Zhang Junbin,et al. Design and application of vacuum gate valve in hypersonic wind tunnel[J]. Chinese Journal of Vacuum Science and Technology,2021,41(12):1125−1129 (侯峰伟,章东林,张峻宾,等. 一种在高超声速风洞中大口径真空插板阀的设计与应用[J]. 真空科学与技术学报,2021,41(12):1125−1129(in chinese) HOU Fengwei, ZHANG Donglin, ZHANG Junbin, et al. Design and Application of Vacuum Gate Valve in Hypersonic Wind Tunnel[J]. Chinese Journal of Vacuum Science and Technology, 2021, 41(12): 1125-1129 [2] Pei Haitao,Chen Jiming,Chen Qin,et al. Design and performance analysis of vacuum system in the 0.6 m continuous transonic wind tunnel[J]. Chinese Journal of Vacuum Science and Technology,2021,41(11):1087−1093 (裴海涛,陈吉明,陈钦,等. 0.6 m连续式跨声速风洞真空系统设计及性能分析[J]. 真空科学与技术学报,2021,41(11):1087−1093(in chinese) PEI Haitao, CHEN Jiming, CHEN Qin, et al. Design and Performance Analysis of Vacuum System in the 0.6m Continuous Transonic Wind Tunnel[J]. Chinese Journal of Vacuum Science and Technology, 2021, 41(12): 1125-1129 [3] ZHANG Yi,HONG Rong,YIN Yongtao,et al. Structural strength analysis of large steel vacuum tank and piping system[J]. Mechanical Engineer,2015(10):77−79 (张诣,洪荣,尹永涛,等. 大型钢制真空球罐及管路系统结构强度分析[J]. 机械工程师,2015(10):77−79(in chinese) ZHANG Yi, HONG Rong, YIN Yongtao, et al. Structural Strength Analysis of Large Steel Vacuum Tank and Piping System[J]Mechanical Engineer, 2015(10): 77-79 [4] QI Dawei,LI Zelong,WU Bing,et al. Stability analysis for 20 000 m3 vacuum spheroidal tank[J]. Process Equipment & Piping,2021,58(03):23−27 (齐大伟,李泽龙,吴斌,等. 20000 m3真空球罐结构稳定性分析[J]. 化工设备与管道,2021,58(03):23−27(in chinese) doi: 10.3969/j.issn.1009-3281.2021.03.004 QI Dawei, LI Zelong, WU Bing, et al. Stability analysis for 20 000 m3 vacuum spheroidal tank[J].Process Equipment & Piping, 2021,58(3):23-27. doi: 10.3969/j.issn.1009-3281.2021.03.004 [5] Ge Zhaowen,Fang Wunong,Wang Xiaomei,et al. Process validation and implementation of post weld heat treatment for 10000 m3 spherical tank[J]. Pressure Vessel Technology,2016,33(09):1−10 (戈兆文,房务农,王笑梅,等. 10000 m3球罐焊后热处理工艺验证与实施[J]. 压力容器,2016,33(09):1−10(in chinese) GE Zhaowen, FANG Wunong, WANG Xiaomei, et al. Process Validation and Implementation of Post Weld Heat Treatment for 10000m3 Spherical Tank[J]. Pressure Vessel Technology, 2016, 33(09): 1-10 [6] Ji Fang,Liu Cenfan,Xu Yongsheng,et al. Internal combustion method for spherical tank[J]. Pressure Vessel Technology,2020,37(05):37−43 (吉方,刘岑凡,徐永生,等. 球罐内燃法焊后热处理热工计算方法改进[J]. 压力容器,2020,37(05):37−43(in chinese) JI Fang, LIU Cenfan, XU Yongsheng, et al. Internal Combustion Method for Spherical Tank[J]. Pressure Vessel Technology, 2020, 37(05): 37-43 [7] Feng Jingqiang,Wang Qiang,Deng Guide,et al. Simulation of BP neural network PID temperature controllers of' post weld heat treatment in spherical tanks[J]. Journal of China University of Metrology,2015,26(04):480−485 (冯精良,王强,邓贵德,等. 球罐焊后热处理中BP神经网络-PID温度控制器性能仿真[J]. 中国计量学院学报,2015,26(04):480−485(in chinese) doi: 10.3969/j.issn.1004-1540.2015.04.016 Feng Jingqiang, Wang Qiang, Deng Guide, et al. Simulation of BP neural network PID temperature controllers of' post weld heat treatment in spherical tanks[J]. Journal of China University of Metrology,2015,26(04),480-486. doi: 10.3969/j.issn.1004-1540.2015.04.016 [8] Lin Hongjie,Zhang Jingchun,Li Can. Finite element fatigue analysis of 2000m3 medium pressure spherical air tank[J]. Chemical Engineering & Equipment,2022(11):243−245 (林鸿杰,张景春,李灿. 2000 m3中压空气球罐有限元疲劳分析[J]. 化学工程与装备,2022(11):243−245(in chinese) doi: 10.19566/j.cnki.cn35-1285/tq.2022.11.089 Lin Hongjie, Zhang Jingchun, Li Can. Finite element fatigue analysis of 2000m3 medium pressure spherical air tank [J].Chemical Engineering & Equipment, 2022(11):243-245. doi: 10.19566/j.cnki.cn35-1285/tq.2022.11.089 [9] Ma Tao,Shu Anqing,Ding Keqin. Strength evaluation and fatigue analysis of large air spherical tank with opening structure[J]. Journal of Wuhan Institute of Technology,2020,42(05):563−567 (马涛,舒安庆,丁克勤. 大型空气球罐开孔结构的强度评定及疲劳分析[J]. 武汉工程大学学报,2020,42(05):563−567(in chinese) MA Tao, SHU Anqing, DING Keqin, et al. Strength Evaluation and Fatigue Analysis of Large Air Spherical Tank with Opening Structure[J]. Journal of Wuhan Institute of Technology, 2020, 42(05): 563-567 [10] Huang Si,Yi Tiankun,Ou Chenxi,et al. Buckling analysis of spherical tanks based on measured pillar offset[J]. Journal of Chongqing University of Technology (Natural Science),2023,37(01):315−321 (黄思,易天坤,欧晨希,等. 基于检测支柱偏移的球罐屈曲分析[J]. 重庆理工大学学报(自然科学),2023,37(01):315−321(in chinese) doi: 10.3969/1.issn.1674-8425(z).2023.01.036 Huang Si, Yi Tiankun, Ou Chenxi,et al. Buckling analysis of spherical tanks based on measured pillar offset[J].Journal of Chongqing University of Technology( Natural Science), 2023, 37(01): 315-321. doi: 10.3969/1.issn.1674-8425(z).2023.01.036 [11] Su Wenqiang,Chen Zhiping,Ma He,et al. Buckling analysis of large storage tank under the combined action of uneven settlement and wind load of the foundation[J]. Pressure Vessel Technology,2019,36(03):35−43 (苏文强,陈志平,马赫,等. 地基不均匀沉降和风载荷联合作用下的大型储罐屈曲分析[J]. 压力容器,2019,36(03):35−43(in chinese) SU Wenqiang, CHEN Zhiping, MA He, et al. Buckling Analysis of Large Storage Tank under the Combined Action of Uneven Settlement and Wind Load of the Foundation[J]. Pressure Vessel Technology, 2019, 36(03): 35-43 [12] Zhu Guodong. Design methods for opening reinforcement at cylinders considering axial force or bending moment[J]. Pressure Vessel Technology,2023,40(02):35−45 (朱国栋. 压力容器筒体在计及轴向力或弯矩作用下开孔补强方法[J]. 压力容器,2023,40(02):35−45(in chinese) ZHU Guodong. Design methods for opening reinforcement at cylinders considering axial force or bending moment[J]. Pressure Vessel Technology, 2023, 40(02): 35-45 [13] Liu Mei. Application of open hole reinforcement technology in pressure vessel design[J]. Safety Technology of Special Equipment,2022(05):11−13 (刘梅. 开孔补强技术在压力容器设计中的应用[J]. 特种设备安全技术,2022(05):11−13(in chinese) doi: 10.3969/j.issn.1674-1390.2022.05.005 Liu Mei. Application of open hole reinforcement technology in pressure vessel design[J] Safety Technology of Special Equipment, 2022(5): 11-13. doi: 10.3969/j.issn.1674-1390.2022.05.005 [14] Shao Huyue,Sun Zhigang. Reinforcement calculation of thick-walled tube with large open hole in the cylinder of pressure vessel[J]. Petro & Chemical Equipment,2022,25(06):129-131+125. 邵虎跃,孙志刚. 压力容器筒体大开孔厚壁管补强计算[J]. 石油和化工设备,2022,25(06):129−131+125 doi: 10.3969/j.issn.1674-8980.2022.06.037 [15] Li Xinxin,Guo Yahong,Zhang Lijuan,et al. Open reinforcing calculation of spherical tank forgings[J]. Inner Mongolia Petrochemical Industry,2018,44(12):66−68 (李欣欣,郭亚红,张丽娟,等. 球罐整体补强锻件开口补强计算[J]. 内蒙古石油化工,2018,44(12):66−68(in chinese) doi: 10.3969/j.issn.1006-7981.2018.12.015 Li Xinxin, Guo Yahong, Zhang Lijuan, et al. Open reinforcing calculation of spherical tank forgings[J]Inner Mongolia Petrochemical Industry, 2018,44(12): 66-68. doi: 10.3969/j.issn.1006-7981.2018.12.015 [16] Xu Yongsheng,Yang Zhirong,Sun Liang,et al. Buckling stability analysis of large vacuum spherical tank with opening structure[J]. China Special Equipment Safety,2019,35(03):9−12+25 (徐永生,杨智荣,孙亮,等. 大型真空球罐开孔结构屈曲稳定性分析研究[J]. 中国特种设备安全,2019,35(03):9−12+25(in chinese) XU Yongsheng, YANG Zhirong, SUN Liang, et al. Buckling Stability Analysis of Large Vacuum Spherical Tank with Opening Structure[J]. China Special Equipment Safety, 2019, 35(03): 9-12+25 [17] Wu Xiaohong,Guo Chunguang,Li Yongtai,et al. Stability analysis of external pressure on 10000 m3 vacuum spherical tank[J]. Pressure Vessel Technology,2014,31(07):41−48 (吴晓红,郭春光,李永泰,等. 10000 m3真空球罐的外压稳定性分析[J]. 压力容器,2014,31(07):41−48(in chinese) doi: 10.3969/j.issn.1001-4837.2014.07.008 WU Xiaohong, GUO Chunguang, LI Yongtai, et al. Stability Analysis of External Pressure on 10000m3 Vacuum Spherical Tank[J]. Pressure Vessel Technology, 2014, 31(07): 41-48 doi: 10.3969/j.issn.1001-4837.2014.07.008 [18] Ren Jinping,Chen Shuping,Liu Fulu,et al. Design and calculation of radial reinforcing ribs for large external pressure spherical tanks[J]. Petro-Chemical Equipment,2014,43(01):31−34 (任金平,陈叔平,刘福录,等. 大型外压球罐径向加强筋设计计算[J]. 石油化工设备,2014,43(01):31−34(in chinese) doi: 10.3969/j.issn.1000-7466.2014.01.007 REN Jinping, CHEN Shuping, LIU Fulu, et al. Design and Calculation of Radial Reinforcing Ribs for Large External Pressure Spherical Tanks[J]. Petro-Chemical Equipment, 2014, 43(01): 31-34 doi: 10.3969/j.issn.1000-7466.2014.01.007 [19] Shi Shanshuang,Song Yuntao,Yang Qingxi,et al. Structure stability of vacuum vessel of reversed field pinch KTX[J]. Chinese Journal of Vacuum Science and Technology,2014,34(10):1087−1090 (史善爽,宋云涛,杨庆喜,等. 反场箍缩装置KTX真空室结构稳定性分析[J]. 真空科学与技术学报,2014,34(10):1087−1090(in chinese) SHI Shanshuang, SONG Yuntao, YANG Qingxi, et al . Structure Stability of Vacuum Vessel of Reversed Field Pinch KTX[J ]. Chinese Journal of Vacuum Science and Technology, -

首页

首页 登录

登录 注册

注册

下载:

下载: