-

氮化铝(AlN)是一种性能优异的陶瓷材料,因其高热导率、良好的电绝缘性、优异的压电特性和稳定的化学性质而广泛应用于机械,微电子,光学,传感器和高频宽带通讯器件等领域[1-3] ,还可用于高温元件表面温度的精确测量[4-5] 。在室温条件下,AlN单晶的导热系数可达320 W/mK,得益于其高热导率,氮化铝可用作半导体基片,大规模集成电路,高功率器件,柔性器件的理想散热材料,保证器件正常工作[6-7] 。AlN薄膜还可以作为其他半导体材料,例如GaN, ZnO[8-10] 的缓冲层或隔离层。通过引入AlN缓冲层,可以有效减小衬底与外延层之间的晶格失配和热失配的问题,进而减少薄膜生长过程中产生的缺陷,提高外延薄膜的性能和结晶质量[11-14] 。

AlN薄膜的一些特性具有显著的各向异性。例如,在1150℃下声波传输速度沿a轴和c轴方向分别为5500 m/s和11354 m/s。其中c轴择优取向的AlN薄膜适合应用于体声波(BAW)器件中,而a轴择优取向的AlN薄膜则适合应用于表面声波(SAW)器件中[15] 。AlN薄膜的择优取向对其光学性能也有影响:高c轴取向的AlN薄膜表现出更高的折射率[16] 。可见,掌握调控AlN薄膜择优取向的手段和规律有利于获得更好的薄膜材料特性。此前的研究发现,通过调节溅射气压或者靶基距能够调控AlN薄膜的择优取向:低气压和短靶基距的实验条件有利于沿c轴择优生长,反之则有利于a轴择优生长[17-20] 。通过给衬底施加偏压,利用离子轰击为薄膜生长提供额外能量,也能够实现c轴择优生长[21-22] 。Xie等[23]发现随着靶材和基片台之间的角度变化,可以实现AlN薄膜从a轴择优生长转变成c轴择优生长。Liu[24]发现金刚石基片的晶体质量会显著影响AlN薄膜的择优取向,高度(111)取向的金刚石有利于AlN薄膜沿c轴生长。除此之外,氧杂质的存在也会影响AlN薄膜的择优取向和晶体质量,Bakri[25],Zhang[26],以及AKIYAMA等[27]均在实验中发现:薄膜内较高的氧含量不利于氮化铝沿着(002)择优生长。迄今为止,多数关于AlN薄膜生长取向性的研究利用的是金属衬底(Ir, Ru[28], Pt, W,Mo)或单晶衬底(如蓝宝石或硅)[29] ,在玻璃衬底上制备AlN薄膜的研究还很不充分。S.Shanmugan等[30] 利用直流磁控溅射,在玻璃表面制备出(100)择优的AlN薄膜。然而,由于沉积在室温下进行,结晶性不理想。STAN等[31] 利用射频磁控溅射技术,在玻璃基片上制备了(002)择优的AlN薄膜。但他们只是讨论了衬底和膜厚对结晶性的影响,没有对其他实验条件进行研究。陈勇等[32] 利用中频磁控溅射技术,室温下在玻璃基片上制备AlN薄膜,发现提高N2分压同时降低溅射功率可以使制备的AlN 薄膜由非晶态变为c轴择优的结晶态。总之,目前尚无关于在玻璃衬底上制备AlN薄膜过程中溅射功率、沉积温度、氮分压等实验参数对薄膜结晶性影响的系统性研究报导。

针对这种情况,作者利用中频磁控溅射在玻璃基片上制备AlN薄膜,对溅射功率、沉积温度、特别是氮分压等实验参数对薄膜结晶性的影响进行了研究。在玻璃表面沉积AlN薄膜并实现结晶取向的自主调控,将使玻璃基片表面获得所需的物理性质,拓展廉价的玻璃作为衬底的应用。另一方面,对于AlN这样的绝缘材料薄膜制备,中频磁控溅射能够避免直流磁控溅射所存在的靶面打火、靶中毒和阳极消失等问题,同时具有远高于射频磁控溅射的沉积效率,更加具有产业化的应用前景。

-

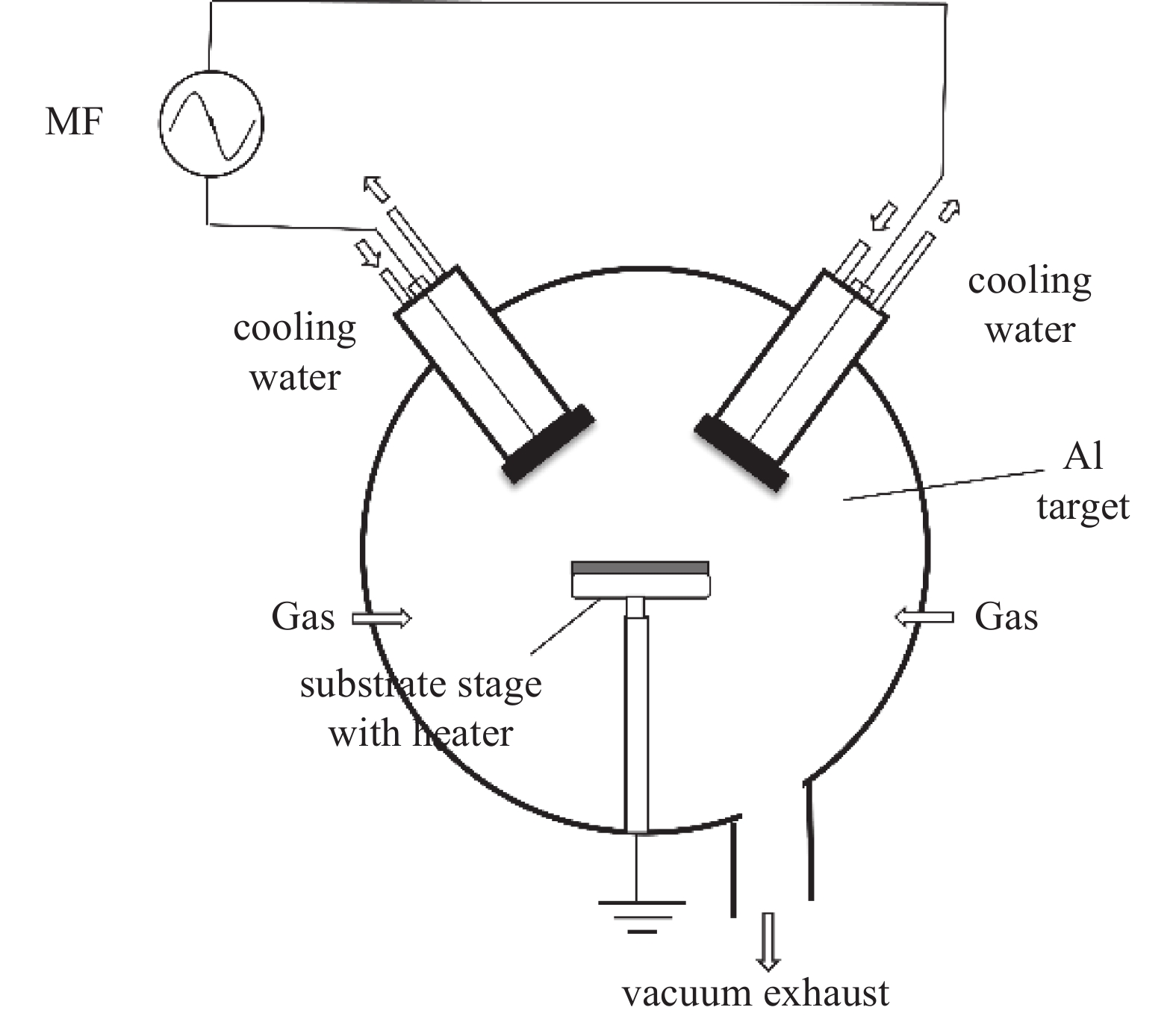

实验在大连理工大学三束材料改性教育部重点实验室自行研制的等离子体增强非平衡磁控溅射系统上进行[33] ,实验装置如图1所示。一对孪生铝靶(直径68 mm,纯度99.9%)间隔10厘米呈120°相对安装于真空室上部,两靶分别连接中频电源(30 kHz)两输出端。实验中,中频电源采用恒功率模式。基片台位于两靶下方,直线距离两靶中心均为11 cm。基片台安装有加热器对基片进行加热,基片温度通过热电偶进行测量。尺寸为30 mm×30 mm×1.1 mm的电子级钠钙玻璃基片,经15 min乙醇超声波清洗和干燥,获得洁净表面后,置于基片台上。实验中首先将本底真空抽至5 mPa,然后通入Ar(30 (mL/min)/0.22 Pa)对靶进行预溅射,再通入N2,利用气体质量流量计调节气体流量,同时调节排气阀使气压稳定在0.5 Pa,待电源输出电压稳定后,移开基片上方的挡板开始沉积。主要实验参数如表1所示。为了避免膜厚差异对薄膜特性的影响,所有薄膜的厚度均控制在500−600 nm。

利用荷兰帕纳科公司Empyrean型X射线衍射仪(

$ {\mathrm{Cu}}{K}_{\mathrm{\alpha }} $ 射线源,$ \mathrm{\lambda } $ =0.154 nm)分析薄膜晶体结构和择优取向;通过日本Kosaka公司的ET200A-01型台阶仪测量AlN薄膜的厚度。使用日本电子株式会社的JSM-7900F型场发射扫描电镜表征了AlN薄膜的表面形貌;采用CSPM5000型原子力显微镜及其图像分析软件Imager分析薄膜表面形貌和粗糙度,扫描面积为2 μm×2 μm。 -

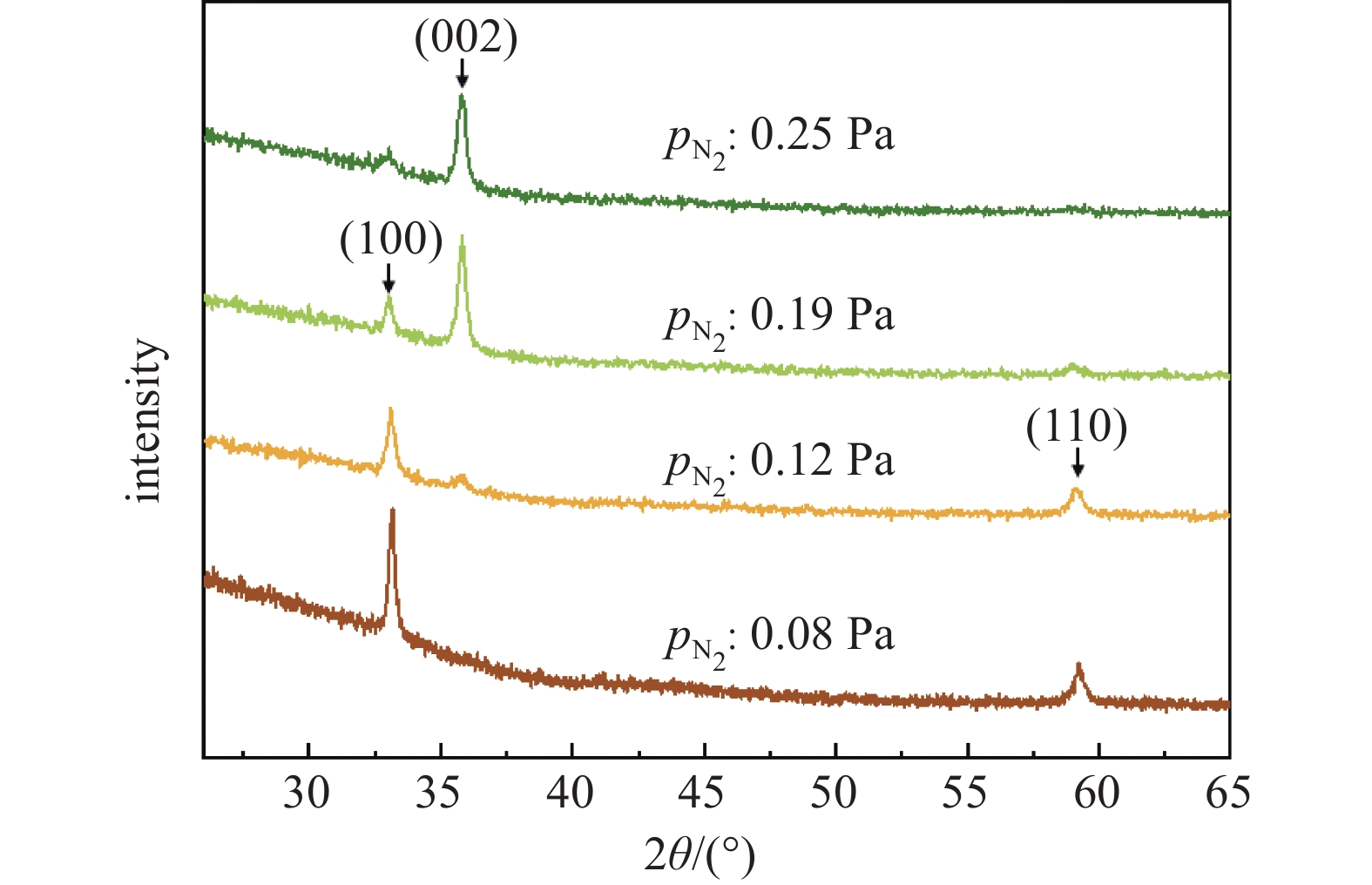

图2是不同氮分压下AlN薄膜的X射线衍射(XRD)谱线,基片温度和溅射功率分别为300℃和1200 W。当氮分压为0.08 Pa时,薄膜呈现为(100)/(110)择优状态。随着氮分压的增加,(002)衍射峰开始出现并逐渐变强。当氮分压增大至0.25 Pa时,(002)衍射峰成为主要的衍射峰,(100)衍射峰变得很弱,显示薄膜转变为c轴择优状态。可见,氮分压是制备AlN薄膜的一个关键参数,对AlN薄膜的择优取向具有直接和显著的影响。较小的氮分压有利于(100)/(110)晶面的生长,而较大的氮分压则有利于(002)晶面的生长。这个结果与利用直流磁控溅射在Si(100)基片上沉积AlN薄膜[34] 以及利用射频磁控溅射在Si(111)基片上沉积AlN薄膜[35] 所得到的结果相同,显示AlN薄膜的择优取向与溅射电压波形和基片表面结构没有相关性。氮分压的不同可能在靶表面氮化和气相碰撞化合两方面引起差异,从而对薄膜的择优取向产生影响。

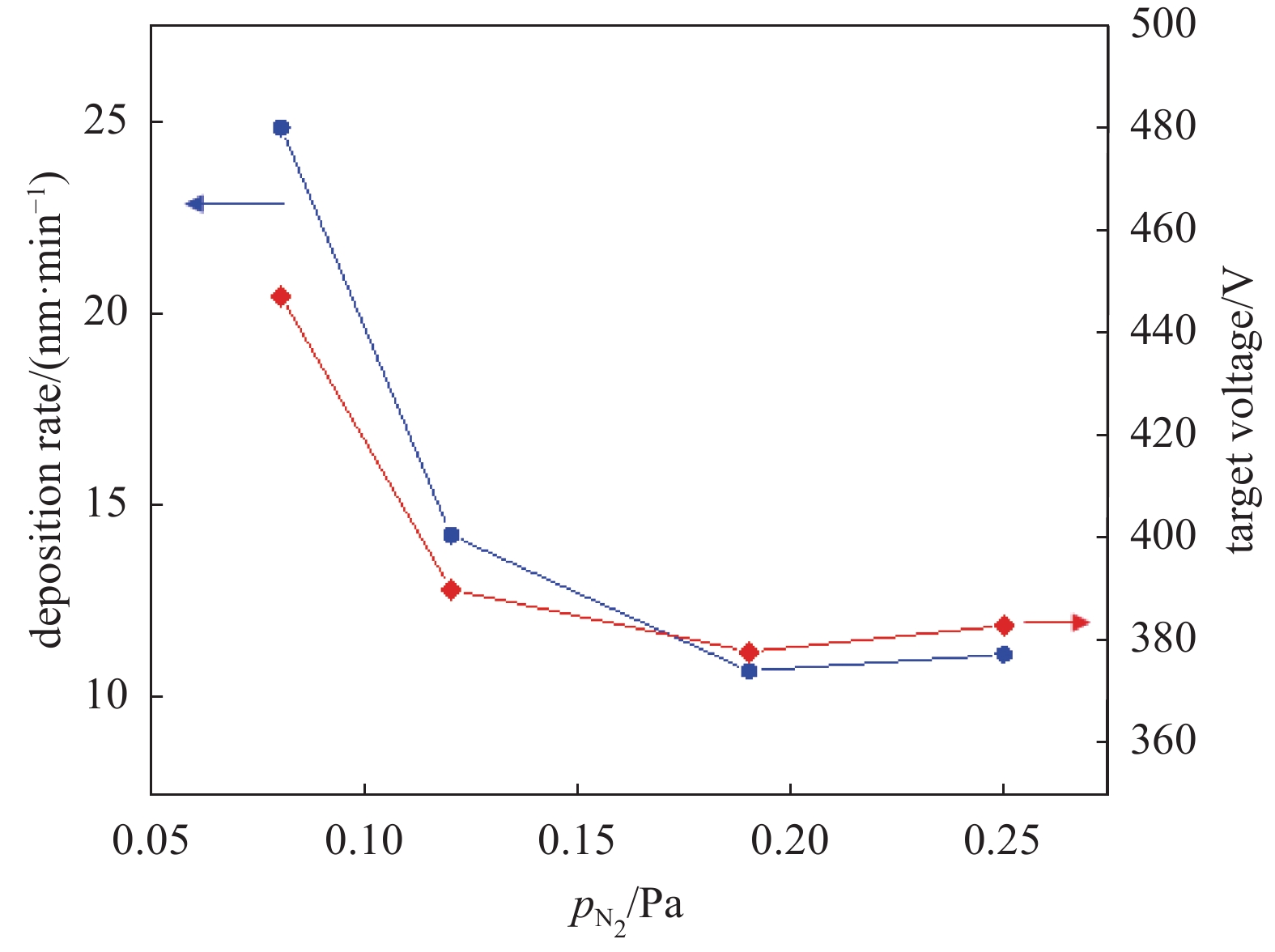

图3所示为沉积率和靶电压随氮分压的变化。可见两者趋势相同,均为从0.08 Pa开始随氮分压增加大幅降低,在0.19 Pa之后趋于稳定。对于沉积速率随氮分压增大而下降的现象,有文献[36-37] 解释为:氩离子比氮离子的溅射产额大,随着氮分压的增大,氩离子比例降低,从而使沉积率减小。然而,这个因素不能完全解释图3的结果,因为总气压维持0.5 Pa,氩分压的增加是近似线性的,这与沉积率的变化不同。因此,作者认为图3中沉积率的下降主要是靶表面氮化造成的[32],即随着氮分压的增大,靶表面氮化程度加重,由于氮化的表面不易被溅射,使得沉积率降低。图3中靶电压的相似变化能够为上述解释提供支持:由于氮化的靶表面具有更大的二次电子发射系数[38-40] ,使得恒定功率下靶电流增大,从而导致靶电压的降低[32]。

溅射制备AlN薄膜的过程中,可能的溅射产物包括Al原子和Al-N基团[1]。由于靶面氮化程度的差异,氮分压为0.08 Pa与0.25 Pa时,气相中溅射产物成分不同:前者含有较多的Al原子和较少的Al-N基团,而后者则相反,含有较少的Al原子和较多的Al-N基团。另一方面,氮分压分别为0.08 Pa和0.25 Pa时溅射产物粒子与N2碰撞的平均自由程也不同。由于溅射产物粒子的定向速度远大于氮分子的热运动速度,可以假定氮分子是静止的,溅射产物粒子与N2碰撞的平均自由程可以由公式

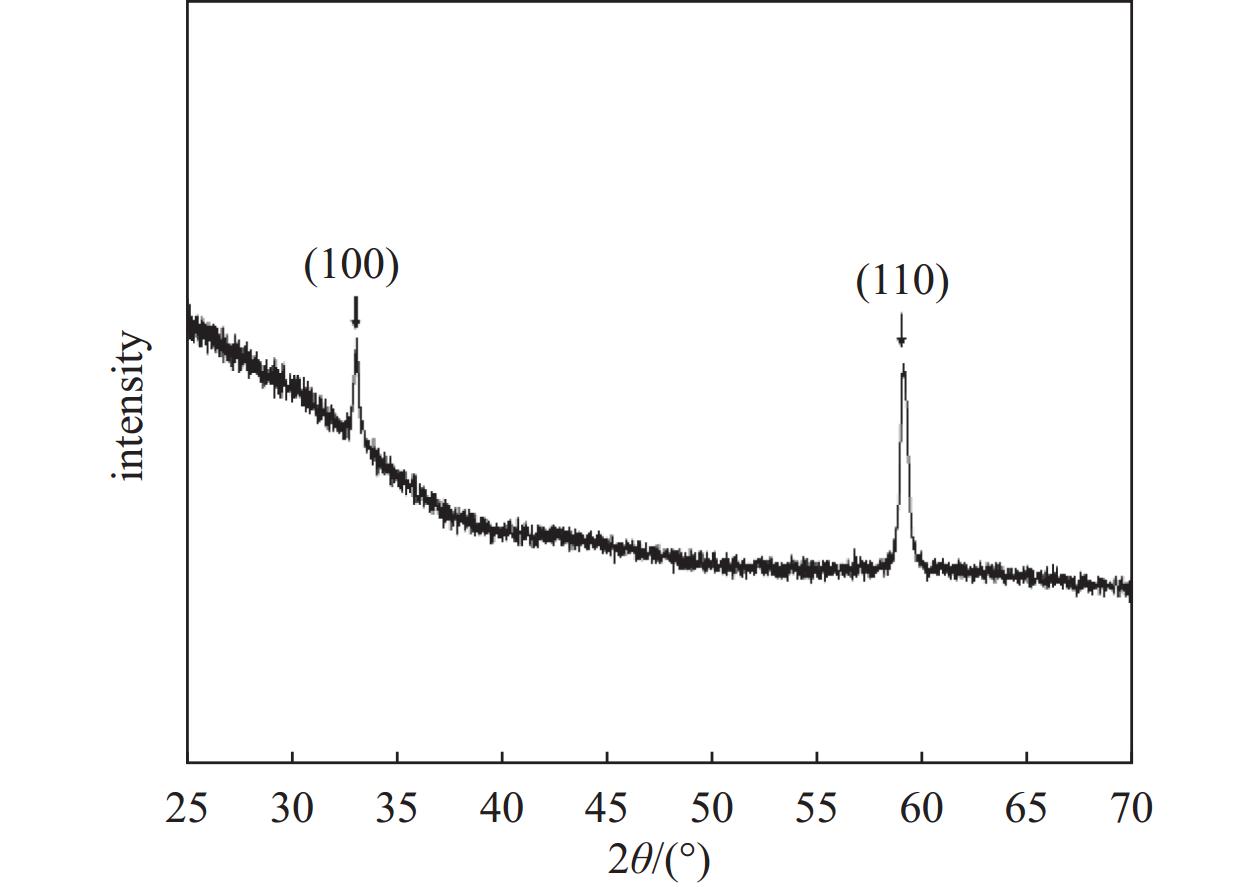

$ \lambda =\sqrt{2}{\lambda }_{0} $ 进行估算 [41],其中$ {\lambda }_{0} $ 是N2间相互碰撞的平均自由程。总气压为0.5 Pa 时,氮分压分别为0.08 Pa和0.25 Pa,对应的$ \mathrm{\lambda } $ 分别为12 cm和3.7 cm,前者大于靶与基片间的距离。由此我们推测,氮分压较低时,由于Al原子缺少靶表面氮化和气相碰撞氮化,AlN薄膜的生长主要由Al原子在基片表面的沉积和氮化支配,易于形成(100)/(110)择优取向结构,而较高氮分压下AlN薄膜的生长主要由Al-N基团的沉积支配,易于形成(002)择优取向结构。为了验证上述设想,设定氮分压为0.36 Pa,然后调节排气阀,使总气压保持在1.5 Pa,在此条件下制备薄膜。此时靶面为氮化状态(靶电压低),沉积由Al-N基团支配。图4为样品的XRD测量结果,显示薄膜为(100)/(110)择优取向,这与图2中氮分压为0.25 Pa条件下的结果不同,说明除气相氮分压外,薄膜结晶取向还受到其他因素的影响。

纤锌矿结构AlN中存在两种Al-N化学键,分别为B1键和B2键。B2键形成能高,较容易断裂,因此形成稳定的B2键需要更高的能量。由于B2键沿[001]晶向,所以(002)择优取向的薄膜生长需要更高的能量[42],能量的来源包括降低沉积气压和/或缩短靶基距以增强高能靶材粒子对膜层的轰击[17-20],衬底施加偏压[21-22],以及升高温度[43-44]等。在实验中,较高气压下(1.5 Pa)没有获得(002)择优取向的原因,推测为溅射粒子在气相输运过程中由于经历更多碰撞使沉积能量较低所致。为此通过改变溅射功率和衬底温度研究粒子能量对AlN薄膜择优取向的影响。

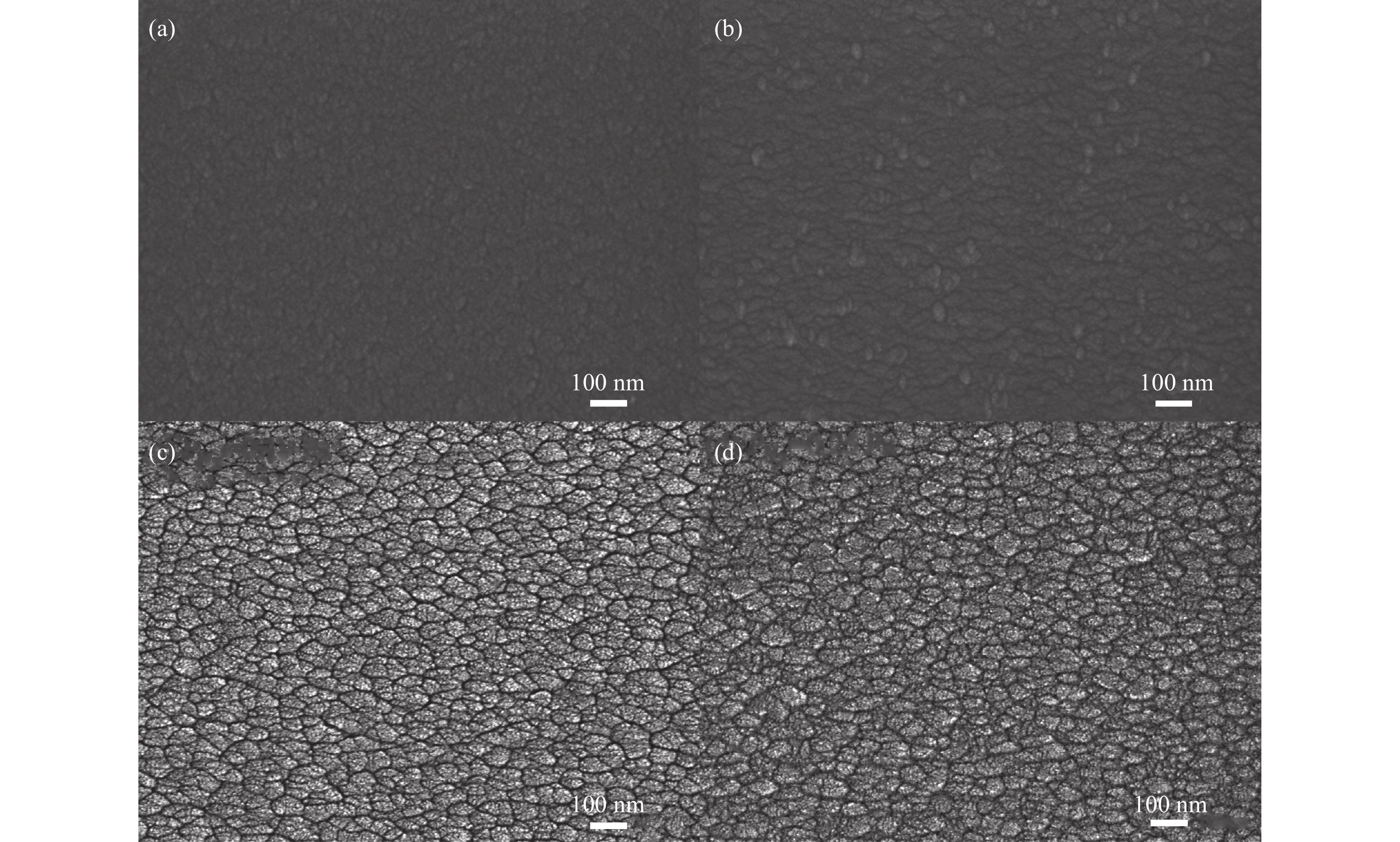

图5是不同氮分压下AlN薄膜的扫描电镜(SEM)图像,基片温度和溅射功率分别为300℃和1200 W。通过SEM图像可以发现,氮分压对AlN薄膜的表面形貌和晶粒尺寸有显著的影响。在较低氮分压下(0.08 Pa),薄膜表面的晶粒大多数为类似于“扁豆”的细长形状;随着氮分压增加至0.19 Pa时,晶粒演变成“颗粒状”的形貌,且晶粒尺寸变大。这是因为氮分压会直接影响薄膜的沉积率,如图3所示。沉积率高,衬底表面的反应粒子没有足够的横向扩散与扩散时间,导致更多的反应粒子在衬底的演变对应了择优取向的转变,当薄膜沿着a轴择优生长时,表面形貌主要类似于“扁豆”的细长形状,如图5(b)所示;当薄膜沿着c轴择优生长时其表面形貌呈现“颗粒状”,是晶粒生长相互挤压的结果。如图5(c),(d)所示。Wei[19]和H. E. Cheng [20]等也观察到了相似的表面形貌。

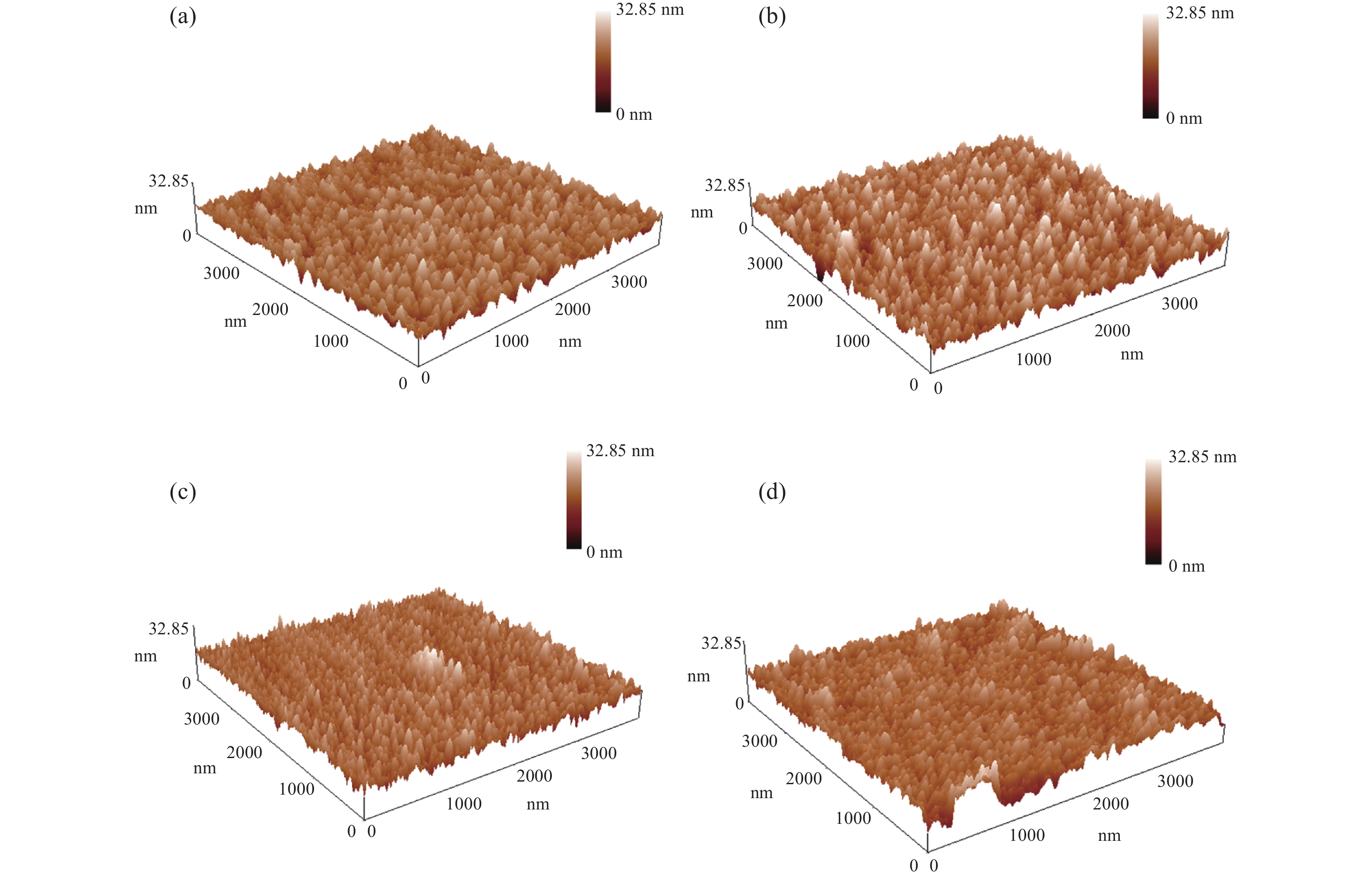

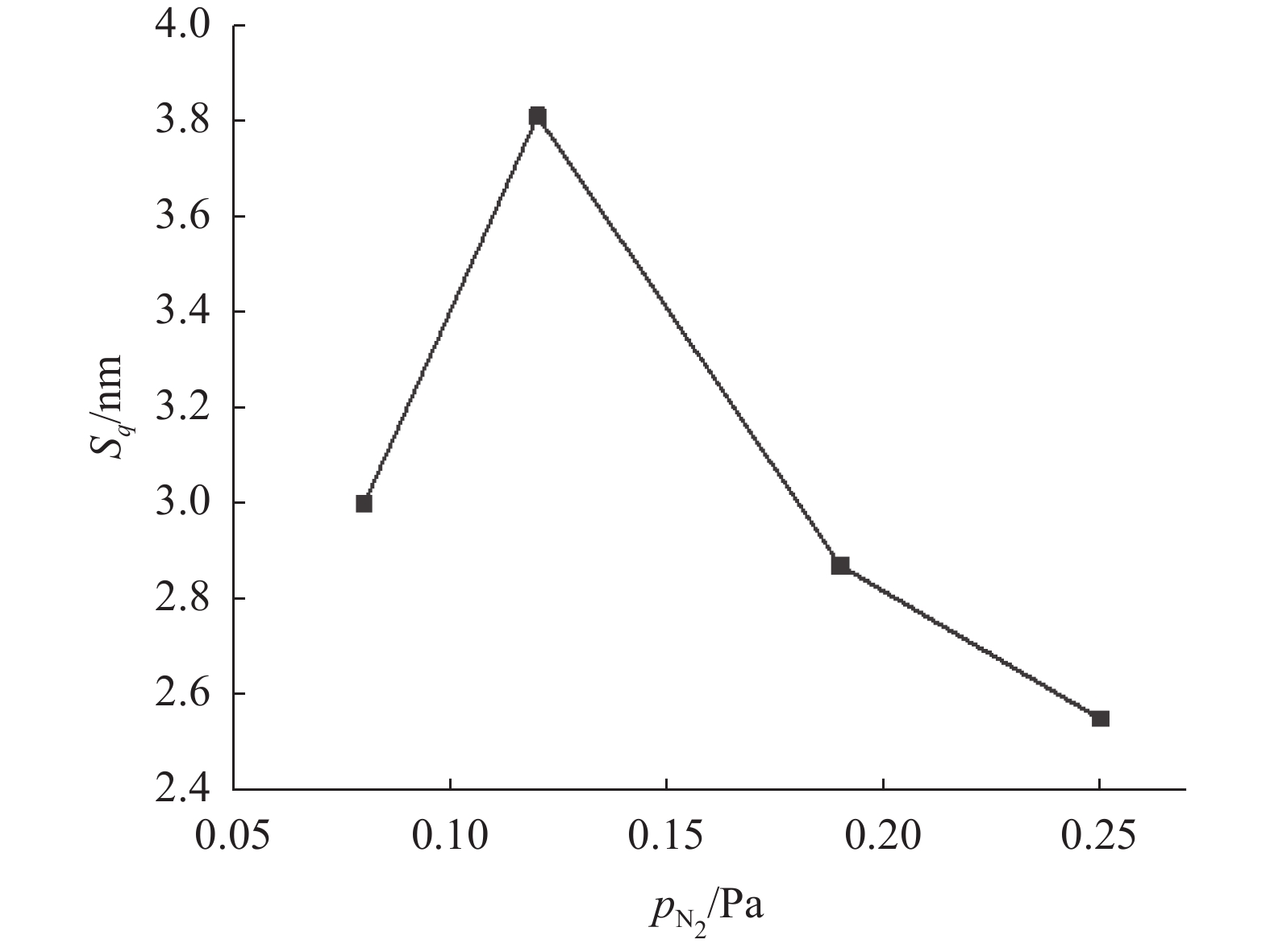

图6是不同氮分压下AlN薄膜的原子力显微镜(AFM)图像,基片温度和溅射功率分别为300℃和1200 W。从AFM图像中可以发现,AlN薄膜表面的颗粒大小分布较均匀、致密。图7展示了AlN薄膜表面的方均根粗糙度(Sq)随氮分压的变化曲线。从图中可见,当氮分压为0.12 Pa时,薄膜的粗糙度最大。随着氮分压再增加,薄膜粗糙度降低。整体而言,氮分压对薄膜的粗糙度影响不大,方均根粗糙度在2.5−3.8 nm 之间,薄膜表面光滑。

-

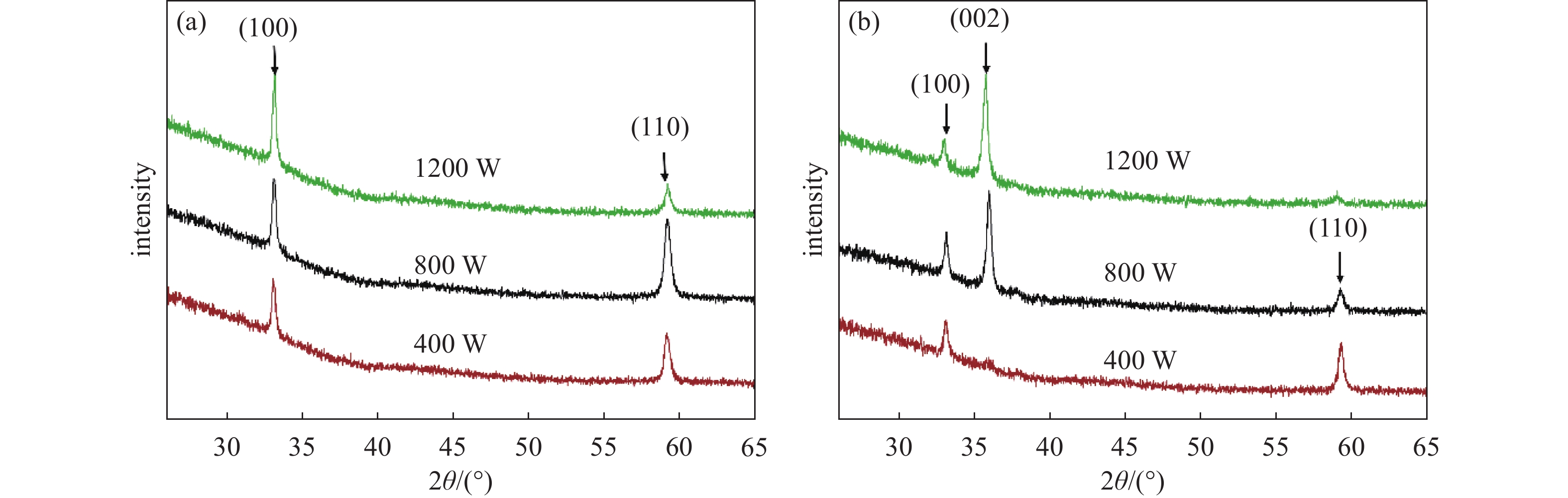

图8 (a)和(b)所示分别为基片温度为300℃时, 氮分压分别为0.08 Pa和0.25 Pa条件下,不同溅射功率下所沉积的AlN薄膜的XRD谱线。当氮分压较低(0.08 Pa)时,所有薄膜都显示为(100)/(110)择优生长。但是对比(100)和(110)峰强可知,低溅射功率相对更有利于(110)择优的生长。随着溅射功率增大,(100)取向逐渐占优,而(110)取向逐渐减少。

另一方面,当氮分压为0.25 Pa时,低溅射功率下(400 W)薄膜为(100)/(110)择优取向;而在增大溅射功率时,强(002)峰出现,同时(100)/(110)峰随溅射功率增大而减弱。在1200 W溅射功率下,(100)/(110)峰变得很弱,(002)峰为主要峰,显示出薄膜为c轴择优生长的结构。由于溅射功率可以定性代表粒子的能量,图8的结果清晰地展示了入射粒子的能量对AlN薄膜择优取向的影响。

-

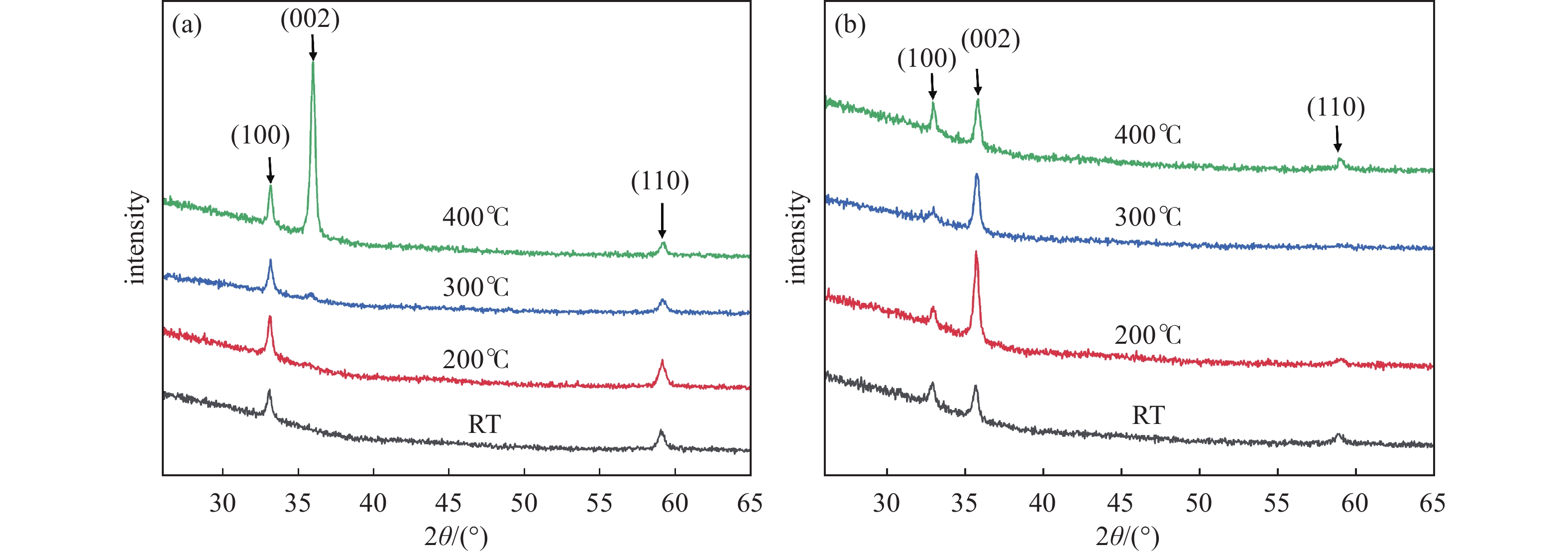

图9 (a)和(b)所示分别为溅射功率1200 W条件下,当氮分压为0.12 Pa和0.25 Pa时,不同基片温度下所沉积的AlN薄膜的XRD谱线。当基片温度低于300℃时(室温除外),薄膜取向与氮分压的关系与前述规律相同,即低氮分压下(0.12 Pa)为(100)/(110)择优生长,而高氮分压下(0.25 Pa)为(002)择优生长。然而当基片温度达到400℃时,0.12 Pa氮分压下生长的薄膜从(100)择优转变成(002)择优(图9 (a))。根据Thornton的结构区域模型[45],利用基片加热和载能粒子轰击为薄膜生长提供能量,对薄膜结构的影响作用相同。因此,图9 (a)进一步证实了提高粒子能量是AlN薄膜(002)择优生长的必要条件。

另一方面,当基片温度达到400℃时,氮分压为0.25Pa时,生长的薄膜出现了明显的(100)/ (110)峰(图9 (b))。类似的现象也在Hasheminiasari等[44],Jin[46]等以及Wei[19]等的研究中被观察到。作者推测这是高温下沉积原子在薄膜内的体扩散所导致的多晶化现象[46]。

基于实验结果,可以得到利用中频磁控溅射在玻璃表面制备氮化铝薄膜的规律。首先衬底温度应设定在200℃−300℃范围,过低的温度下薄膜中将包含更多的非晶结构,而过高的温度下薄膜会趋于多晶化。另一方面,在维持稳定放电和正常沉积率的前提下,选择较低的沉积气压和适当的靶基距,以减小溅射粒子在气相中的碰撞能量损失,为薄膜生长提供能量。在上述条件的基础上,通过调节气相环境中的氮分压,可以实现AlN薄膜择优取向的自主调控。

-

利用中频磁控溅射在玻璃表面制备氮化铝薄膜,对氮化铝薄膜择优取向的影响因素进行了研究。结果发现,适合制备择优取向AlN薄膜的条件是低气压和200℃−300℃的基片温度。气相中的氮分压和粒子能量是影响AlN薄膜择优取向的两个主要因素。较低的氮分压和粒子能量有利于获得(100)/(110)择优生长的薄膜,其中相对于(100)取向,较低的能量更有利于(110)的择优生长。另一方面,较高的氮分压和粒子能量则有利于获得(002)择优生长的薄膜。本文的结果可以为玻璃表面氮化铝薄膜的制备和应用提供参考。

玻璃表面中频磁控溅射制备氮化铝薄膜的晶面择优取向调控

Orientation Control of Aluminum Nitride Thin Films Prepared by Mid-Frequency Magnetron Sputtering on Glass Substrates

-

摘要: 氮化铝(AlN)是一种性能优异的陶瓷材料,在微电子、电子元件、高频宽带通信以及功率半导体器件等领域有广泛应用,然而AlN薄膜的一些特性具有显著的各向异性。因此,调控AlN 薄膜的择优取向一直备受科研工作者的关注。文章利用中频反应磁控溅射在玻璃基片上制备AlN薄膜,研究了氮分压、溅射功率以及基片温度对AlN薄膜特性的影响。结果发现,适合制备择优取向AlN薄膜的条件是低气压和200℃−300℃的基片温度,气相中的氮分压和粒子能量是影响AlN薄膜择优取向的两个主要因素。较低的氮分压和粒子能量有利于获得(100)/(110)择优生长的薄膜,其中相对于(100)取向,较低的沉积能量更有利于(110)的择优生长,而较高的氮分压和粒子能量则有利于获得(002)择优生长的薄膜。研究结果为玻璃表面氮化铝薄膜的制备和应用提供参考。Abstract: Aluminum nitride (AlN) is a ceramic material with excellent performance, which is widely used in microelectronics, electronic components, high-frequency broadband communication, and power semiconductor devices, but some properties of AlN thin films exhibit significant anisotropy. Therefore, controlling the preferred orientation of AlN thin films has always been a concern for scientific researchers. In this paper, Aluminum nitride (AlN) thin films were prepared on glass substrates by mid-frequency reactive magnetron sputtering. The influence of the nitrogen partial pressure, the sputtering power and the substrate temperature on the crystal structure of the films were investigated. It is found that the condition for the preparation of AlN films with a preferred orientation is low pressure and a substrate temperature between 200℃−300℃. The most important factors that influence the preferred orientation of the AlN films are the nitrogen partial pressure in the circumstance and the particle energy deposited on the substrate. The results showed that lower nitrogen partial pressure and particle energy are preferable for (100)/(110) oriented growth, with (110) further preferred at lower energies, while higher nitrogen partial pressure and particle energy were beneficial to obtain (002) preferential growth films. The results are helpful in the preparation and application of AlN films on glass substrates.

-

Key words:

- Mid-frequency magnetron sputtering /

- Glass substrate /

- AlN thin film /

- Orientation .

-

-

表 1 中频磁控溅射制备AlN薄膜的实验参数

Table 1. Experimental parameters for mid-frequency magnetron sputtering of AlN thin films

氮分压 $ p_{\mathrm{_{N_2}}} $ /Pa基片温度Ts/℃ 功率P/W 0.08 300 400, 800, 1200 0.12 RT,200,300,400 1200 0.19 300 1200 0.25 300 400, 800, 1200 0.25 RT,200,300,400 1200 -

[1] Fei C, Liu X, Zhu B, et al. AlN piezoelectric thin films for energy harvesting and acoustic devices[J]. Nano Energy,2018,51:146−161 doi: 10.1016/j.nanoen.2018.06.062 [2] Murillo A E, Lizbeth M M, Brenda G F, et al. Development of AlN thin films for breast cancer acoustic biosensors[J]. Journal of Materials Research and Technology,2019,8(1):350−358 doi: 10.1016/j.jmrt.2018.02.007 [3] Fu Y Q, Luo J K, Nguyen N T, et al. Advances in piezoelectric thin films for acoustic biosensors, acoustofluidics and lab-on-chip applications[J]. Progress in Materials Science,2017,89:31−91 doi: 10.1016/j.pmatsci.2017.04.006 [4] Dong L, Li Y, Lv J, et al. Fabrication of weak c-axis preferred aln thin film for temperature measurement[J]. Sensors (Basel),2021,21(16):1−7 doi: 10.1109/JSEN.2021.3101730 [5] Dong L, Li Y, Lv J, et al. High temperature lattice structure evolution of C-axis preferred orientation AlN thin films and its application in temperature measurement[J]. Ceramics International,2023,49(1):607−612 doi: 10.1016/j.ceramint.2022.09.029 [6] Bian Y, Liu M, Ke G, et al. Aluminum nitride thin film growth and applications for heat dissipation[J]. Surface and Coatings Technology,2015,267:65−69 doi: 10.1016/j.surfcoat.2014.11.060 [7] Duquenne C, Besland M P, Tessier P Y, et al. Thermal conductivity of aluminium nitride thin films prepared by reactive magnetron sputtering[J]. Journal of physics d-applied physics,2012,45:015301 doi: 10.1088/0022-3727/45/1/015301 [8] Wang W, Chen C, Zhang G, et al. The function of a 60-nm-thick AlN buffer layer in n-ZnO/AlN/p-Si(111)[J]. Nanoscale Research Letters, 2015, 10 (91) [9] Zhao X M. Effects of the sputtering time of AlN buffer layer on the quality of ZnO thin films[J]. Advanced Materials Research,2014,881-883:1117−1121 doi: 10.4028/www.scientific.net/AMR.881-883.1117 [10] Liu Y, Li Z, Yang Z, et al. Novel design and performance of the solidly mounted resonator with an AlN-buffered ZnO piezoelectric film[J]. Vacuum,2018,154:11−17 doi: 10.1016/j.vacuum.2018.03.050 [11] Yoshida S, Misawa S, Gonda S. Improvements on the electrical and luminescent properties of reactive molecular beam epitaxially grown GaN films by using AIN-coated sapphire substrates[J]. Applied physics letters,1983,42:427−429 doi: 10.1063/1.93952 [12] Yang J H, Kang S M, Dinh D V, et al. Influence of AlN buffer layer thickness and deposition methods on GaN epitaxial growth[J]. Thin Solid Films,2009,517(17):5057−5060 doi: 10.1016/j.tsf.2009.03.089 [13] 王敬蕊, 叶志镇, 赵炳辉, 等. AlN缓冲层对提高硅基GaN薄膜质量的作用机理及其研究进展[J]. 真空科学与技术学报,2006,26:308−312 (in Chinese) Wang J R, Ye Z Z, Zhao B H, et al. Influence of AlN buffer layer on GaN film growth on Si(111) substrates[J]. Journal of Vacuum Science and Technology,2006,26:308−312 [14] Zhu X, Wu J, Cheng Y, et al. 2 in. Free-standing GaN grown by HVPE with sputtered AlN buffer on GaAs substrate[J]. Journal of Crystal Growth,2020,540:125637 doi: 10.1016/j.jcrysgro.2020.125637 [15] Rafael R C, B Aspar, N Azema, et al. Morphological properties of chemical vapour deposited AlN films[J]. Journal of Crystal Growth,1993,133:59−70 doi: 10.1016/0022-0248(93)90103-4 [16] Ababneh A, Albataineh Z, Dagamseh A M K, et al. Optical characterization of sputtered aluminum nitride thin films – correlating refractive index with degree of c-axis orientation[J]. Thin Solid Films,2020,693:137701 doi: 10.1016/j.tsf.2019.137701 [17] Xu X H, Wu H S, Zhang C J, et al. Morphological properties of AlN piezoelectric thin films deposited by DC reactive magnetron sputtering[J]. Thin solid films,2001,388(1):62−67 [18] Ishihara M, Li S J, Yumoto H, et al. Control of preferential orientation of AlN films prepared by the reactive sputtering method[J]. Thin solid films,1998,316(1):152−157 [19] Wei Z X, Shen L H, Kuang Y, et al. The evolution of preferred orientation and morphology of AlN films under various sputtering parameters[J]. Journal of Crystal Growth,2024,625:127439 doi: 10.1016/j.jcrysgro.2023.127439 [20] Cheng H E, Lin T C, Chen W C. Preparation of (002) oriented AlN thin films by mid frequency reactive sputtering technique[J]. Thin Solid Films,2003,425:85−89 doi: 10.1016/S0040-6090(02)01137-9 [21] Clement M, Iborra E, Sangrador J, et al. Influence of sputtering mechanisms on the preferred orientation of aluminum nitride thin films[J]. Journal of applied physics,2003,94(3):1495−1500 doi: 10.1063/1.1587267 [22] Tavsanoglu T. Synthesis of c-axis oriented AlN thin films at room temperature[J]. Surface engineering,2017,33(4):249−254 doi: 10.1080/02670844.2016.1235522 [23] Xie B W, Ding F Z, Shang H J, et al. Substrate angle-induced fully c-axis orientation of AlN films deposited by off-normal DC sputtering method[J]. Rare Metals,2021,40(12):3668−3675 doi: 10.1007/s12598-020-01675-z [24] Liu H, Xu Y H, Zhang X, et al. Orientation of AlN grains nucleated on different diamond substrates by magnetron sputtering[J]. Physica Status Solidi A-Applications and Materials Science,2018,215(23):1800447 [25] Bakri A S, Nafariza N, Abu Bakar A S, et al. Electrical and structural comparison of (100) and (002) oriented AlN thin films deposited by RF magnetron sputtering[J]. J Mater Sci: Mater Electron,2022,33(15):12271−12280 doi: 10.1007/s10854-022-08186-w [26] Zhang X Y, Peng D C, Yan J H, et al. Plasma power effect on crystallinity and density of AlN films deposited by plasma enhanced atomic layer deposition[J]. Journal of Materials Research and Technology,2023,27:4213−4223 doi: 10.1016/j.jmrt.2023.10.302 [27] Morito A, Xu C N, Hagio T, et al. Influence of sputtering target material on crystallinity and orientation of AIN thin films[J]. Journal of the Ceramic Society of Japan,2002,110(2):115−117 [28] Inoue S, Okamoto K, Nakano T, et al. Characteristics of single crystalline AlN films grown on Ru(0001) substrates[J]. Journal of Crystal Growth,2006,297(2):317−320 doi: 10.1016/j.jcrysgro.2006.09.051 [29] Olivares J, Capilla J, Clement M, et al. Growth of AlN oriented films on insulating substrates[C]//2011 IEEE International Ultrasonics Symposium. Orlando, FL, USA:IEEE, 2011: 1716−1719. [30] Shanmugan S, Mutharasu D, Anithambigai P, et al. Synthesis and structural properties of DC sputtered AlN thin films on different substrates[J]. Journal of Ceramic Processing Research,2013,14:359−390 [31] Stan G E, Pasuk I, Galca A C, et al. Highly textured (001) aln nanostructured thin films synthesized by reactive magnetron sputtering for saw and fbar applications[J]. Digest Journal of Nanomaterials and Biostructures,2010,5:1041−1054 [32] 陈勇, 袁军林, 段丽, 等. 中频磁控反应溅射AlN薄膜及微观结构研究[J]. 真空,2010,47(01):34−38 (in Chinese) Chen Y, Yuan J L, Duan L, et al. AlN films deposited by MF reactive magnetron sputtering and its microstructure[J]. Vacuum,2010,47(01):34−38 [33] 黄佳楠, 陆文琪, 徐军. 双靶共溅射沉积碳掺杂AlN薄膜的光学性能研究[J]. 真空科学与技术学报,2022,42(7):504−510 (in Chinese) Huang J N, Lu W Q, Xu J. Study on the optical properties of co-sputtering deposited carbon-doped AlN thin films[J]. Chinese Journal of Vacuum Science and Technology,2022,42(7):504−510 [34] 王强文, 郭育华. 氮氩体积流量比对AlN薄膜生长取向、晶体质量及沉积速率的影响及机理分析[J]. 微纳电子技术,2023,60(1):154−158 (in Chinese) Wang Q W, Guo Y H. Effects of volume flow rate ratio of nitrogen and argon on the growth orientation, crystal quality and deposition rate of AlN thin films and mechanism analysis[J]. MicronanoelectronicTechnology,2023,60(1):154−158 [35] Jiang X, Wu Y, Qi J, et al. Effect of nitrogen flow ratio on the structure and optical properties of AlN film[J]. Vacuum,2024,220:112829 doi: 10.1016/j.vacuum.2023.112829 [36] Penza M, Dericcardis M F, Mirenghi L et al. Low temperature growth of r. f. reactively planar magnetron-sputtered AlN films[J]. Thin Solid Films,1995,259:154−162 doi: 10.1016/0040-6090(94)06450-4 [37] Uesugi K, Shojiki K, Xiao S, et al. Effect of the sputtering deposition conditions on the crystallinity of high-temperature annealed AlN films[J]. Coatings (Basel),2021,11(8):956 doi: 10.3390/coatings11080956 [38] 许小红, 武海顺, 张富强, 等. 反应溅射制备AlN薄膜中沉积速率的研究[J]. 稀有金属材料与工程,2002,31(3):209−212 (in Chinese) Xu X H, Wu H S, Zhang F Q, et al. Study on deposition rate of AlN thin films using reactive magnetron sputtering[J]. Rare Metal Materials And Engineering,2002,31(3):209−212 [39] 乔保卫, 刘正堂, 李阳平, 等. 工艺参数对磁控反应溅射AIN薄膜沉积速率的影响[J]. 西北工业大学学报,2004,22(2):260−263 (in Chinese) Qiao B W, Liu Z T, Li Y P, et al. Effect of technicalparameters on deposition rate of AlN films prepared by magnetron reactive sputtering[J]. Journal of Northwestern Polytechnical University,2004,22(2):260−263 [40] 茅昕辉, 陈国平, 蔡炳初. 反应磁控溅射的进展[J]. 真空,2001,4:1−7 (in Chinese) Mao X H, Chen G P, Cai B C. Advance in reactive magnetron sputterin[J]. Vacuum,2001,4:1−7 [41] 达道安. 真空设计手册(第二版)[M]. 1991, 北京: 国防科技出版社:37 (in Chinese) Da D A. Vacuum Design Handbook (Second Edition)[M]. 1991, Beijing: National Defense Science and Technology Press:37 [42] Cheng H, Sun Y, Zhang J X, et al. AlN films deposited under various nitrogen concentrations by RF reactive sputtering[J]. Journal of Crystal Growth,2003,254(1-2):46−54 doi: 10.1016/S0022-0248(03)01176-X [43] Zhang J H, Peng W B, Zhou Y, et al. Optimization of growth parameters of AlN thin films and investigation of electrical and electroluminescence characteristics from Au/i-AlN/n-GaN UV light-emitting diode[J]. Optics & Laser Technology,2022,156:108470 [44] Hasheminiasari M, Lin J. Substrate heating effect on c-axis texture and piezoelectric properties of AlN thin films deposited by unbalanced magnetron sputtering[J]. JOM (1989),2016,68(6):1667−1671 doi: 10.1007/s11837-016-1893-2 [45] Thornton J A. High rate thick film growth[J]. Annual Review of Materials Science,1977,7:239−260 doi: 10.1146/annurev.ms.07.080177.001323 [46] Jin H, Feng B, Dong S R, et al. Influence of substrate temperature on structural properties and deposition rate of AlN thin film deposited by reactive magnetron sputtering[J]. Journal of Electronic Materials,2012,41:1948−1954 doi: 10.1007/s11664-012-1999-4 -

首页

首页 登录

登录 注册

注册

下载:

下载: