HTML

-

The next-generation wearable electronics will be foldable, flexible and even stretchable [1-3]. These wearable electronics can deform as needed, they have brilliant adaption ability and can be widely used in irregular surfaces [4, 5]. Moreover, the deformability of wearable electronics also improves their portability and comfort [6, 7]. However, traditional lithium batteries are rigid and the battery dominates the total mass of small electronics. Therefore, the power modules have been one of the most important factors hindering the development of wearable electronic devices [8, 9]. There is an increasing demand for power modules that are continuable, wearable and even stretchable [10, 11]. The triboelectric nanogenerator (TENG), a newly invented energy-harvesting technology based on the coupling effect of triboelectrification and electrostatic induction [12, 13], has been demonstrated to convert mechanical energy into electricity, especially irregular and low-frequency human motion energy [14, 15]. Recently, the TENG has been rigorously explored for harvesting energy from body motion to develop self-powered electronics [16-18].

Stretchability is of great significance for wearable TENGs and has been extensively studied [10, 19-21]. There are two common methods for manufacturing stretchable TENGs. In the first method, using stretchable polymer materials such as polydimethylsiloxane or silicone rubber as the triboelectric and encapsulation layer; liquid metal [22, 23], physiological saline [24], silver nanowires [25] or carbon nanotubes [26] as the stretchable electrode [27, 28]. Alternatively, depositing a conductive material on a pre-stretched triboelectric layer leads to the formation of a conductive film with wrinkled structures [29, 30], which allows the material to be stretched to a pre-stretched value. However, both methods are highly dependent on the mechanical properties of materials, which greatly limits the choice of materials. Therefore, achieving its stretchability through structural design rather than material selection is meaningful. The kirigami approach is a promising method for developing a highly stretchable TENG [31, 32], which has been successful applied to transforming rigid materials into highly stretchable ones [33-35].

In this study, highly stretchable kirigami-patterned nanofiber-based TENGs (K-TENGs) are developed based on electrospinning and the kirigami approach. Porous polyvinylidene fluoride (PVDF) is sprayed onto the surface of copper foil with a conductive adhesive layer by an electrostatic spinning process. Then, stretchability is achieved by processing using the kirigami method. The K-TENG can stretch up to 220%, which can be conformally applied to the human body or irregular and movable objects, showing great potential in the field of wearable electronics. After sewing the K-TENG on clothes, it can effectively convert the biomechanical energy generated by human movement into electrical energy. The electrical energy can directly drive 50 LED lights or a digital watch, and it can also be stored in a lithium battery to charge a smartwatch or smartphone. K-TENG is expected to have large application potential in the field of self-powered wearable electronics.

-

PVDF has both triboelectric and piezoelectric properties and can collect various forms of mechanical energy (such as squeezing and contact-separation movements). Therefore, PVDF is selected as the triboelectric material. The PVDF nanofibrous membrane was fabricated through an electrospinning machine. The machine consists of a syringe pump connected to an injection syringe, a high-voltage direct current (DC) power supply and a grounded collector. The N,N-dimethylformamide (DMF)/acetone mixture (the DMF/acetone was mixed at a volume ratio of 2:3) for the solvent and the mass fraction of the PVDF solute was 12 wt%. A magnetic stirrer was used to mix the prepared solution in a water bath at 40 °C for 5 h until the solution becomes clear. The stirred solution was then injected by the microinject pump into the metal needle of the injection syringe with 0.3 ml h−1 volume flow rate. The applied voltage was 15 kV, and the distance between the needle and the collector was 12 cm so that the polymer solution was fully stretched and jetted from the needle to the collector.

-

The surface structure of the PVDF nanofiber film was tested using A ZEISS Sigma 500 scanning electron microscope (SEM). An oscillator, whose frequency can be adjusted, was used to impact the K-TENG. The PVDF/Cu electrode (2 cm × 2 cm) was attached to an acrylic panel surface. A piece of cotton of the same size was attached to a Cu film as another electrode and it was fixed onto the surface of the oscillator. The distance between the PVDF/Cu electrode and cotton/Cu electrode was set at 3 mm. When the oscillator worked, the cotton and PVDF thin-film surfaces were periodically in contact with each other. The electrical output of the K-TENG was measured by a Keysight DSOX2012A oscilloscope and a Keithley 6514 system electrometer. The contact angle was measured by a Zhongchen JC2000D2. Tensile tests of the K-TENGs were performed using a Mark-10 ESM 303.

-

The PVDF solution was sprayed directly onto the Cu film with a conductive adhesive layer to form the PVDF/Cu electrode. The kirigami-patterned PVDF/Cu electrode (10 cm × 13 cm) was sewn into the underarm of the garment. A Cu foil with kirigami structure was attached inside the sleeve of the cotton to be the cotton/Cu electrode. When people swing their arms while walking or running, the K-TENG converts biomechanical energy into electrical energy. The generated electricity can directly drive small electronics or be stored in a lithium battery for backup.

2.1. PVDF nanofibrous membrane fabrication

2.2. Characterization and measurements

2.3. K-TENG designs on clothes

-

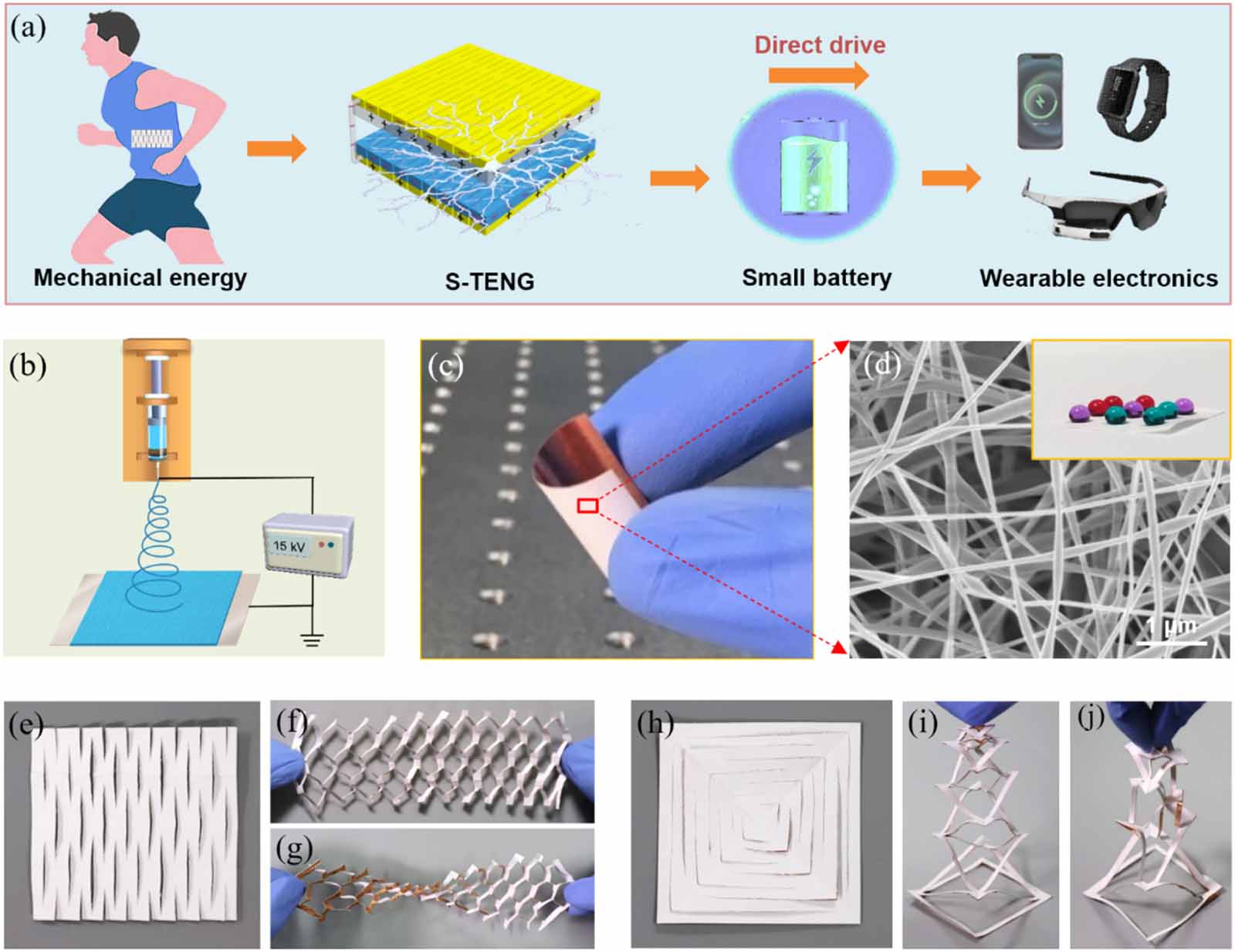

The inconvenience of charging or replacing batteries in wearable electronic devices is an important bottleneck that hinders the development of wearable devices. Here, we attempt to convert the biomechanical energy generated by human movement into electrical energy to charge these wearable electronic devices. The energy harvesting system is illustrated in figure 1(a). The generator can be integrated into the clothing, and when the body moves, the clothing contacts and separates from the generator to generate electricity. It can be directly used to drive low-power wearable electronic devices such as digital watches and night running lights or stored in lithium batteries to charge wearable electronic devices such as smartwatches and smartphones.

Highly stretchable K-TENGs are developed based on electrostatic spinning and the kirigami approach. PVDF has both triboelectric and piezoelectric properties, so it can collect many forms of mechanical energy, including squeezing and contact-separation movements. Therefore, PVDF is selected as the triboelectric material. The schematic diagram of the electrospinning process of porous PVDF film is shown in figure 1(b). Charged droplets of PVDF form a jet flow under the action of a high-voltage electric field. The jet flow is then directly sprayed onto the Cu film with a conductive adhesive layer. Figure 1(c) shows a bent K-TENG, which illustrates excellent flexibility. Figure 1(d) shows that the PVDF thin film prepared by electrospinning has many nanofibers, which are evenly distributed on the surface of the film. These nanofiber structures provide the PVDF thin film with high porosity and large specific surface area, which not only enhances the electrical output performance of K-TENG, but also endows it with excellent hydrophobic properties. Figure S1(a) (supporting information) shows that the contact angle of the porous PVDF thin film is 130°. Therefore, as a wearable device, it has excellent self-cleaning performance. As shown in figure S1(b) (supporting information), water droplets can carry away the stains on the surface of the film.

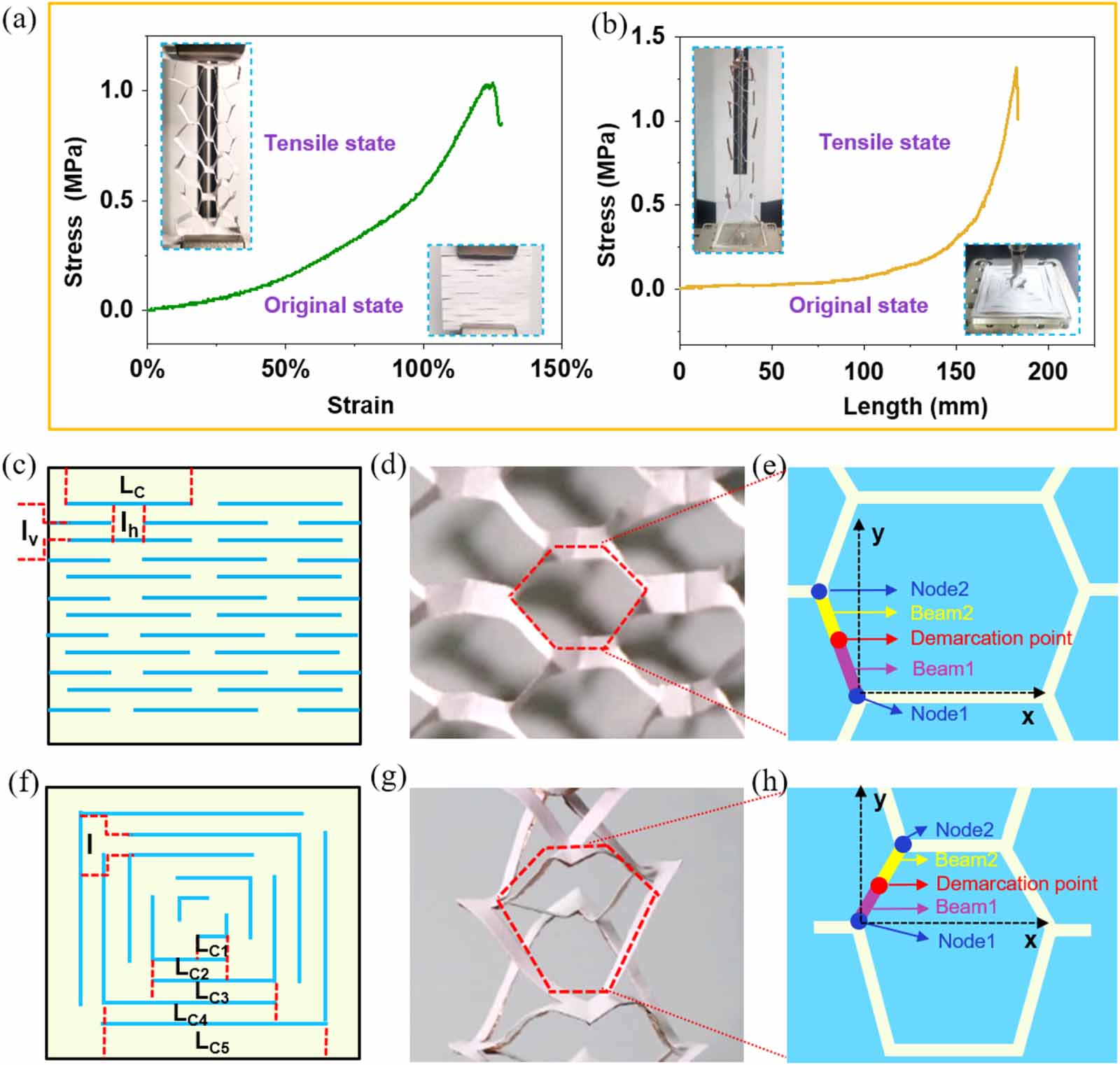

Stretchability can be achieved by two different kirigami patterns, uniaxial kirigami-patterned and biaxial kirigami-patterned, as shown in figures 1(e) and (h), respectively. They can achieve 2D and 3D stretching, respectively. Figure 1(f) shows the stretching state of uniaxial K-TENGs. The stretching length can reach 220% of its original length. Figure 1(i) is the stretching state of biaxial K-TENGs. It can be observed, in the figure, that biaxial K-TENGs have excellent stretching capacity in 3D space. In addition, the K-TENGs have good flexibility, as illustrated in figures 1(g) and (j). The K-TENGs can be twisted in the stretching state and still maintain satisfactory morphological characteristics.

-

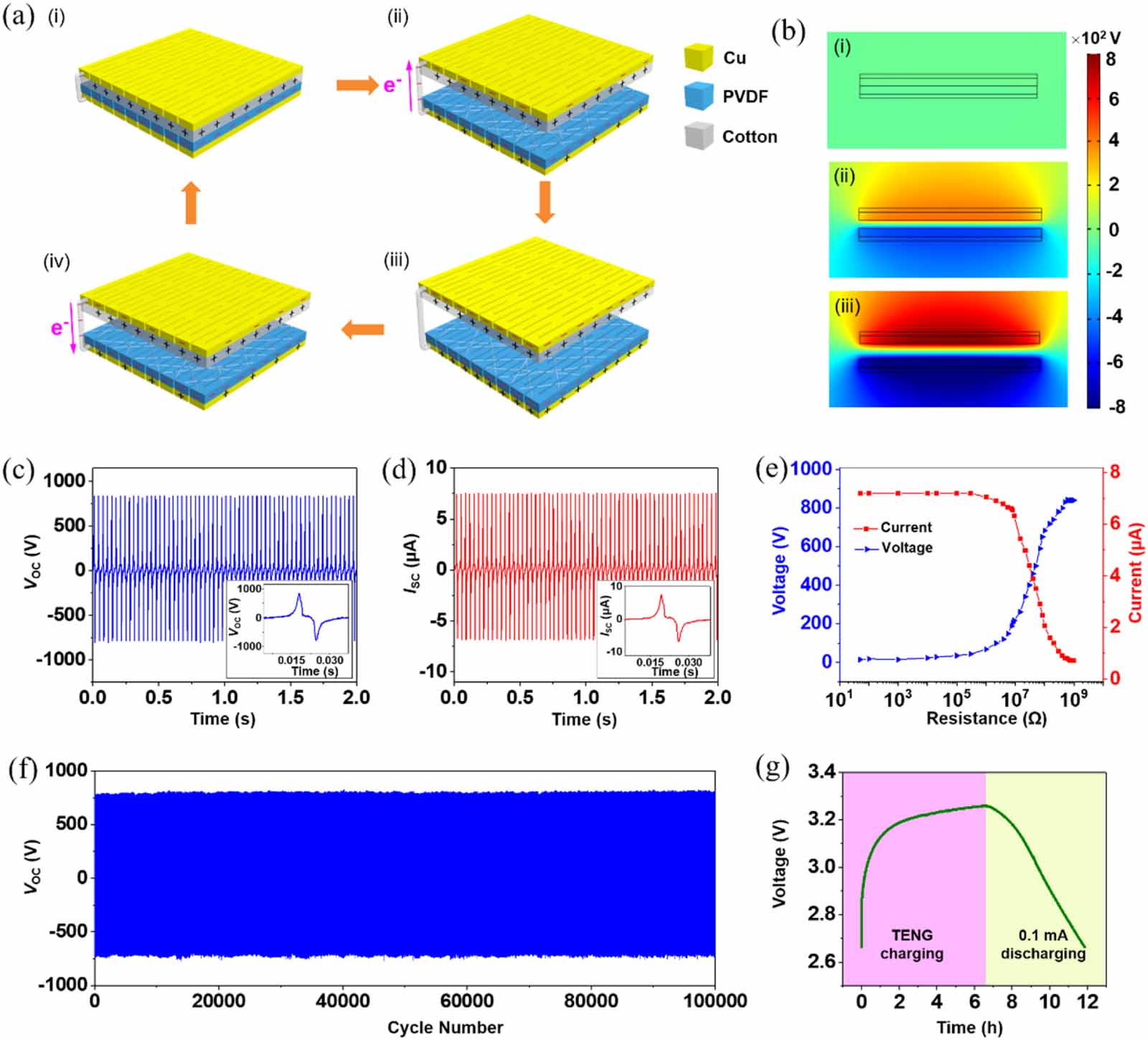

Figure 2(a) expounds the process of the K-TENG harvesting biomechanical energy. At the original stage, due to the electron affinity difference, when the cotton contacts with the PVDF film, charge transfer occurs at the interface, leading to positive charges on the cotton and negative charges on the PVDF (figure 2(a-i)). As the two electrodes separate, the surfaces contacted before form a potential difference along with the whole process, which prompts electrons to move from the bottom electrode to the top electrode through external loads (figure 2(a-ii)). When the electrodes move towards the maximum gap distance, the K-TENG ceases the electron transfer process and reaches the steady state (figure 2(a-iii)). When the K-TENG accepts external impact again, the two electrodes move closer to each other and drive electrons from the top electrode back to the bottom electrode (figure 2(a-iv)). With this cyclical process, the K-TENG is capable of continuously gathering power from the human biomechanical motion. To understand the working principle of the K-TENG, the electric potential distribution can be verified through numerical simulation using COMSOL software. As shown in figure 2(b), when the top electrode is separated from the bottom electrode, the potential difference increases within a certain range as the distance between the two electrodes increases. This is quite in accord with the working mechanism of the K-TENG.

The electrical output performance of the K-TENG is tested under a fixed oscillation frequency (30 Hz). Figure S2 (supporting information) shows the schematic diagram of the test device. The two electrodes are placed opposite to each other and are driven by the oscillator to contact and separate from each other. The valid contact area of periodic contact-separation motion is 2 cm × 2 cm. An open-circuit voltage (VOC) of 840 V is obtained, as shown in figure 2(c). Meanwhile, a short-circuit current (ISC) of 7.4 μA is generated, as demonstrated in figure 2(d). The insets of figures 2(c) and (d) show that the voltage and current graphs of each period are similar in periodic contact-separation motion. Then, to further understand the power generation capacity of the K-TENG, the amount of power generated in one cycle is analyzed. The variation of the output current over a complete contact-separation period is displayed in figure S3 (supporting information). The output charge is calculated by integrating the I-t curve in figure S3(a) (supporting information). As shown in figure S3(b) (supporting information), the amount of charge for the corresponding contact-separation period is 19.8 nC. In addition, the output power under different resistances is studied. As depicted in figure 2(e), the output voltage grows with the increase in load resistance until it reaches a maximum of 840 V, while the current shows an opposite trend due to the consumption of resistance. Figure S4 (supporting information) illustrates the instantaneous output power density. The maximum peak power density reaches 4.48 Wm−2 at a resistance of 40 MΩ. Furthermore, the stability and durability of K-TENG is tested under the oscillation frequency of 30 Hz. As shown in figure 2(f), the VOC still remains stable (the VOC remains around positive 840 V) after over 100 000 cycles of operation. The K-TENG exhibits excellent stability and electrical output performance. To demonstrate the capability of the K-TENG as a DC power source, a rectifier circuit is utilized to convert the alternating current input to DC output. Figure S5 (supporting information) shows the rectified VOC of the K-TENG. A 4.7 μF capacitor is charged by the K-TENG at different impact frequencies, as shown in figure S6 (supporting information). When the frequencies increase from 10 to 30 Hz, the saturation voltage of the capacitor is changed from 18.9 to 44.3 V. At the same time, the time to reach the saturation voltage becomes shorter. Moreover, a small lithium battery is substituted for the capacitor. Figure 2(g) exhibits the process of charging a lithium battery with the K-TENG at an oscillation frequency of 30 Hz. The lithium battery is then discharged at a constant current of 0.1 mA with a discharge capacity of 0.5 mAh. The power produced by the K-TENG is able to recharge a lithium battery, which means that the K-TENG is expected to provide a new way of charging lithium batteries.

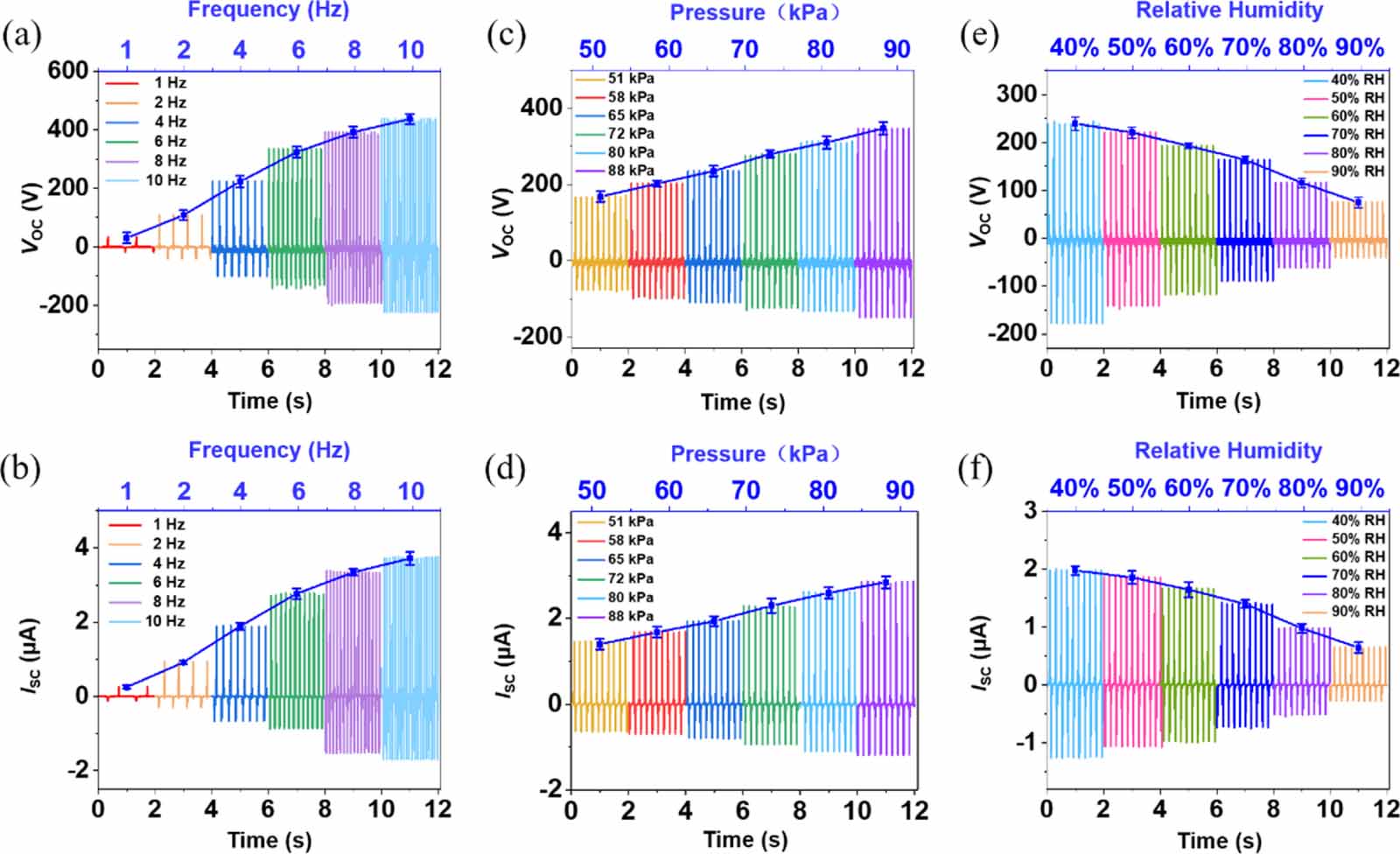

In addition, to further study the performance of the K-TENG, the electrical outputs are experimentally measured under different oscillation frequencies, contact force and atmospheric humidity. A 2 cm × 2 cm K-TENG is used to conduct pertinent experiments. As shown in figures 3(a) and (b), frequency is the main factor that affects the performance of the K-TENG. When the oscillation frequency is changed from 1 to 10 Hz, the VOC increases from the minimum of 30 V to the maximum of 437 V, and the ISC simultaneously increases from 0.25 to 3.72 μA. One possible reason is that along with the increase in frequency, it would induce more charge transfer within the same time, leading to an increase in electrical output. In addition, the electrical output of K-TENG is closely related to the contact force. As illustrated in figure 3(c), the frequency is fixed at 5 Hz and the VOC increases along with the increase in pressure. The VOC increases from 168 V (when the pressure is 51.0 kPa) to 347 V (when the pressure is 88.5 kPa). The trend of the ISC is the same as that of the VOC, as exhibited in figure 3(d), and it also increases from 1.4 to 2.8 μA. The result is due to the rough surface of the PVDF film and cotton. Under the action of a slight contact force, the porous PVDF film cannot fully contact the cotton, and the contact area increases with the increase in the contact force. This also validates that pressure is a determining factor in the electrical output of the K-TENG. Furthermore, environmental humidity can also influence the performance of the K-TENG. The electrical output of the K-TENG under various relative humidity (RH) from 40% to 90% is given in figures 3(e) and (f). It can be obviously observed that the electrical output decreases with increasing humidity. In a highly dry environment (RH 20%), the VOC and ISC can reach 240 V and 2 μA; in a very wet environment (RH 90%), the K-TENG is still able to work but the VOC and ISC decrease to 75 V and 0.65 μA. In addition, to verify whether the cutting has any effect on the electrical output, the VOC before and after cutting is tested. As shown in figure S7 (supporting information), there is no significant change in the electrical output before and after cutting, which shows that the cutting has no effect on the electrical output.

-

The K-TENG has good tensile properties. Among them, the uniaxial K-TENG is in a position to stretch up to 220% and withstands tension greater than 1.0 MPa (figure 4(a)). The insets of figure 4(a) show the original and tensile states of the uniaxial K-TENG, respectively. The biaxial K-TENG can be stretched to 180 mm in 3D space and withstands tension greater than 1.25 MPa. As shown in figure 4(b), the initial section of the stress-strain curve is gentle and linear, and the rear section of the curve increases sharply, which is caused by the shear tearing force.

Thus, the relationship between strain and stress is linear. Furthermore, due to the fact that it is difficult to ensure the same property of each incision during the manufacturing process, the initial stretched driving force of each incision is different. In the initial stage of stretching, the incision units, which can act as beams are small, so the growth of the stress will be slow. In the middle stage, stress-strain will well correspond to a linear relationship. In the rear stage, the shear tearing force at the end of the incision plays a major role and will result in a sharp increase in stress. The stress-strain curves in figure 4(a) well match the above analysis.

-

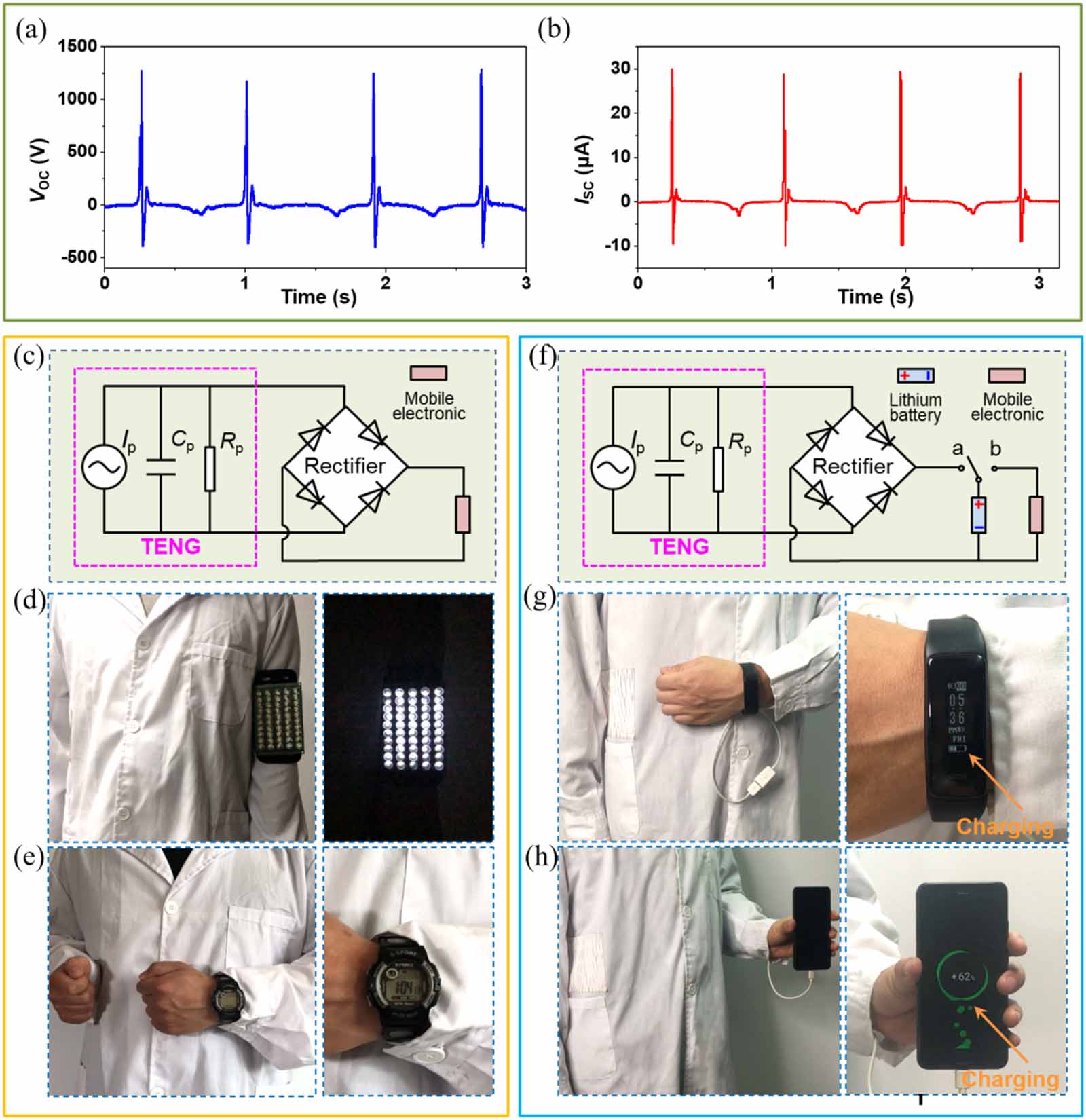

K-TENGs are flexible, stretchable, breathable and wearable, allowing them to be conformally applied to the human body to harvest mechanical energy from daily human motion. To prove K-TENG’s ability to act as a sustainable power source, a K-TENG (13 cm × 10 cm) is made to harvest energy from the body’s motion according to the demand of the actual working environment. The PVDF/Cu as an electrode is integrated under a person’s arm; a Cu foil with kirigami structure is attached inside the cotton sleeve to be the cotton/Cu electrode. When a person swings their arms, the K-TENG can convert the mechanical energy from human movement into electrical energy. Figures 5(a) and (b) show that VOC and ISC are generated by the person walking or running, with peak values of 1230 V and 30 µA, respectively. Figure S8(b) (supporting information) shows a charge of 217 nC for one contact-separation cycle, which is calculated by integrating the I-t curve in figure S8(a) (supporting information).

We show that the K-TENG can be used in wearable electronic devices as a sustainable power source. We use two methods to power wearable devices; directly driving small electronic devices and storing power in small lithium batteries to charge wearable devices. In most instances, the AC pulsed output produced by the K-TENG cannot meet the needs of electronics, because most of the electronics require DC power sources to drive. Therefore, a rectifier is used to convert the AC pulse output into a DC output. Some small wearable electronic devices have low power, so the K-TENG can collect the mechanical energy of the human body to directly drive these small electronic devices. Figure 5(c) shows an equivalent circuit diagram of a power supply system for direct drive wearable electronics. As you can see, 50 white LED lights are lit (figure 5(d) and movie S1, supporting information) and the digital watch is driven and timed accurately by the power supply system (figure 5(e) and movie S2, supporting information).

Some wearable electronic devices are too powerful to be driven directly and require storage units to accumulate energy. As shown in figures 5(f) and S9 (supporting information), when connecting the K-TENG, a rectifier bridge and a lithium battery are required to form a self-charging power system. The system can convert mechanical energy from daily human motion into electricity and store it in a lithium battery. In the charging process, the switch is connected to a, and K-TENG converts mechanical energy from human movement into electrical energy. In the discharge process, the switch is connected to b, and the lithium battery releases the power stored in the charging process to charge the wearable electronic equipment. As demonstrated in figures 5(g) and (h), a smartwatch and a smartphone are connected to the self-charging power system by a USB cable. In the initial stage, because the energy stored in the lithium battery is not sufficient, the self-charging power system could not charge the smartwatch or the smartphone. The self-charging power system converts mechanical energy into electricity and is stored in a lithium battery when the person is their swinging arms. Once the lithium battery accumulates enough charges, it can be used to charge a smartwatch (figure 5(g) and movie S3, supporting information) and a smartphone (figure 5(h) and movie S4, supporting information), respectively. It is clear that K-TENG will play an important role in the development of self-powered electronic equipment.

3.1. Structural design and preparation methods

3.2. Working mechanism and electrical output

3.3. Tensile properties and calculations

3.4. Application of K-TENGs to collect energy from human movement

-

In summary, a highly stretchable K-TENG based on electrospinning and kirigami patterns is demonstrated. K-TENG can be conformally applied to the human body or irregular and movable objects, showing great potential as wearable power modules. The K-TENG (13 cm × 10 cm) is sewn onto clothes. When a person swings their arms, it can convert mechanical energy into electricity. The VOC and ISC can reach 1230 V and 30 µA, respectively, which can directly drive 50 LEDs or a digital watch. Electrical energy can also be stored in a lithium battery. When the lithium battery accumulates enough electricity, it can be used to charge a smartwatch and a smartphone, respectively. K-TENG has great application prospects in the field of wearable electronic devices.

-

Power supply is a bottleneck in the development of wearable electronic devices. At present, wearable electronic devices usually rely on traditional chemical batteries for energy supply, which limits the sustainability of wearable electronics. Harvesting human motion energy to supply wearable electronic devices is an ideal way to realize in situ power solutions. Obtaining energy from the human body without affecting its normal activities is becoming increasingly important. TENG is a newly invented energy harvesting technology. It can efficiently convert low-frequency, irregular mechanical energy generated by human movement into electrical energy. In this study, a flexible, wearable and highly stretchable K-TENG is developed based on electrospinning and the kirigami approach. It can efficiently convert biomechanical energy from human motion into electrical energy. The insitu energy solution for wearable electronics is expected to extend the standby time of electronic devices and even enable self-powering.

首页

首页 登录

登录 注册

注册

DownLoad:

DownLoad: