-

SiC陶瓷以其高熔点(约2700℃)、耐氧化性和低密度等优异性能而被广泛应用。这些特性赋予其出色的高温稳定性、耐热性和抗辐射性[1-2],使其被视为在航空航天和核反应堆领域具有巨大潜力的材料。然而,因为SiC陶瓷本身的脆性,导致其加工性能不好,所以采用合适的连接技术来连接显得至关重要[3]。目前SiC陶瓷与其自身的连接方法有钎焊、扩散焊、前驱体连接、玻璃相连接等[4]。与其他连接方法相比,钎焊适用性广泛,能够满足各种形状和尺寸的SiC零件的不同连接需求。

Ni基钎料以其出色的高温性能和抗腐蚀性而被广泛应用,但接头焊缝中很容易生成石墨相[5]。刘自豪等[6]使用NiTi基钎料成功连接了SiC陶瓷,NiTi基钎料与SiC的反应时,Ni-Ti合金液相中的Ti优先发生反应,界面将优先生成TiC,消耗了C元素,成功消除了焊缝中的石墨相,接头平均室温剪切强度为125 MPa。Anurag Kamal等[7]发现在Ni-30Si钎料中添加8%的Mo可以有效抑制石墨的产生,将石墨转化为Mo2C+Ni3Mo3C相,接头的剪切强度为107 MPa,比含石墨的接头高出近三倍。Zikang Wang等[8]制备了Ni-Mo填充合金用于钎焊SiC陶瓷。Ni3Mo3C和Ni2Si化合物在钎焊接缝的中心,接头的强度为室温下为174±11 MPa,当试验温度为700℃、800℃、900℃时,强度保留率分别为92.5%、79.8%、67.2%,认为高熔点相的形成发挥了重要作用。上述研究都成功连接了SiC陶瓷,但也存在一些不足,使用Ni-30Si钎料中添加8%的Mo得到的接头剪切强度较低;Ni-Mo填充合金用于钎焊SiC陶瓷,其保温时间过长,达40 min。因此,为了提高接头的力学性能,减少其钎焊保温时间,采用Ni-Ti-Mo钎料对SiC陶瓷真空钎焊。

-

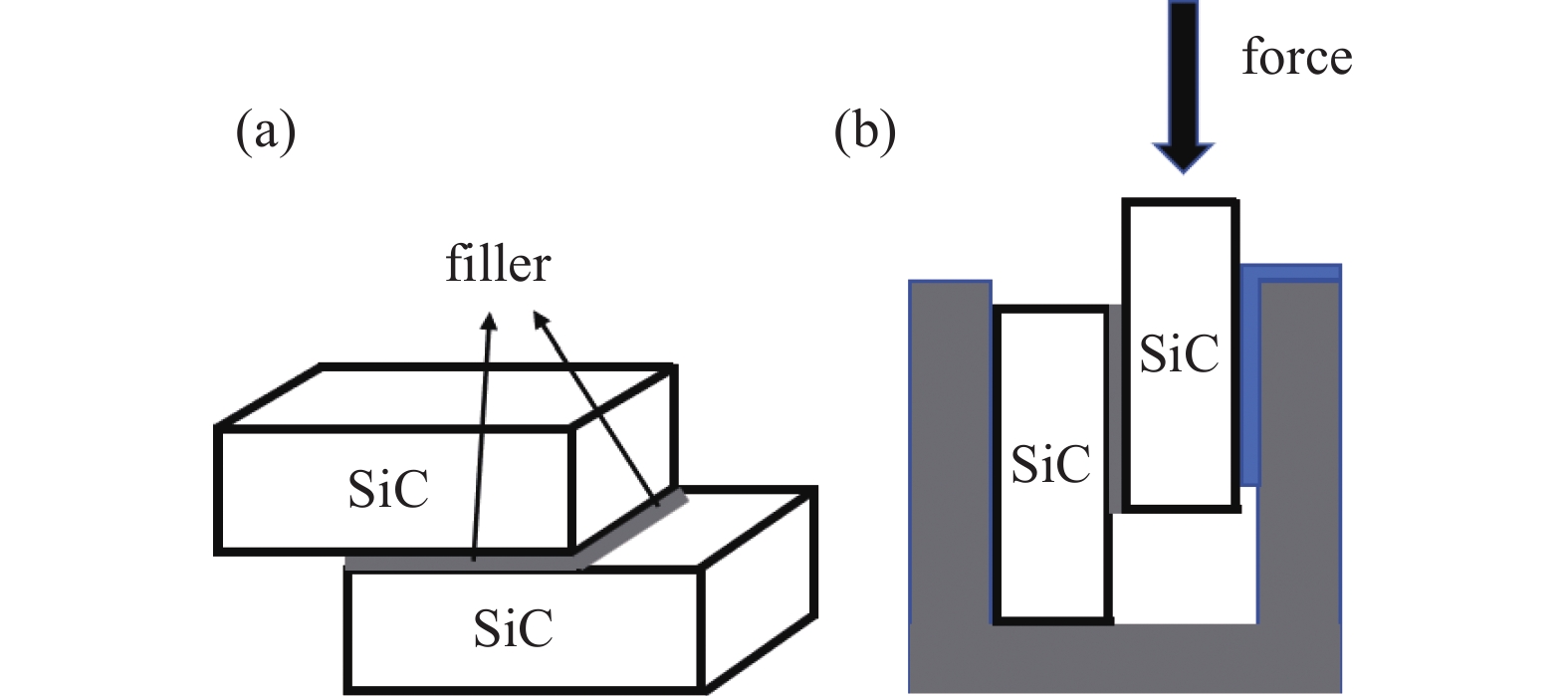

实验所用母材为SiC陶瓷为无压烧结法制备,尺寸为15 mm×10 mm×5 mm。首先,使用800目和1500目的金刚石磨盘对母材进行打磨,然后进行超声波清洗。接着,将Ni-Ti-Mo膏状钎料均匀涂抹在待焊接的SiC陶瓷表面上。随后,将涂有钎料的两块SiC陶瓷按图1(a)所示进行搭接。钎焊实验在VQS-335真空钎焊炉中进行,钎焊工艺步骤如下:首先以10℃/min的速度升温至450℃并保温5 min;然后以10℃/min的升温速度加热至1350℃并保温10 min,以确保液态钎料与母材充分反应。随后随炉冷却至室温进行取样,钎焊过程中的真空度始终保持在5×10−3 Pa以下。

随后,使用扫描电子显微镜(SEM)和能量色散光谱仪(EDS)对制备的SiC接头进行微观形貌表征;采用X射线衍射仪(XRD)对断面进行物相分析;使用万能试验机以0.5 mm/min的速度测试SiC接头的力学性能。为确保数据准确性,如图1(b)所示,进行了4次测试以获取平均值。

-

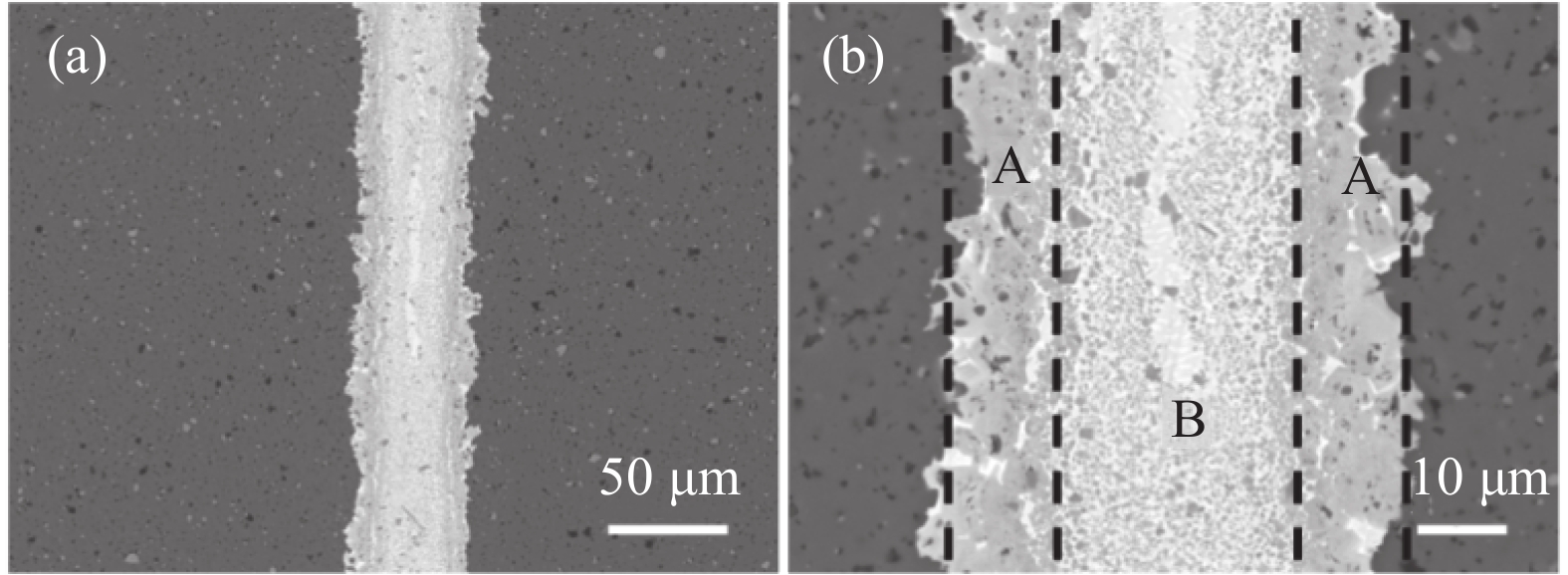

图2为SiC/Ni-Ti-Mo/SiC钎焊接头微观组织的SEM图片。钎料在两块陶瓷的表面铺展,接头连续且致密,没有发现裂纹和孔洞,表明实现了良好的连接,从图2(b)中可以看出焊缝由两个区域组成,一个是Ti、Mo与SiC形成的界面反应区,宽度约为10 μm (标记为区域A);另一个是由Mo、Ni、Ti和Si组成的焊缝中心区,宽度约为26 μm (标记为区域B)。

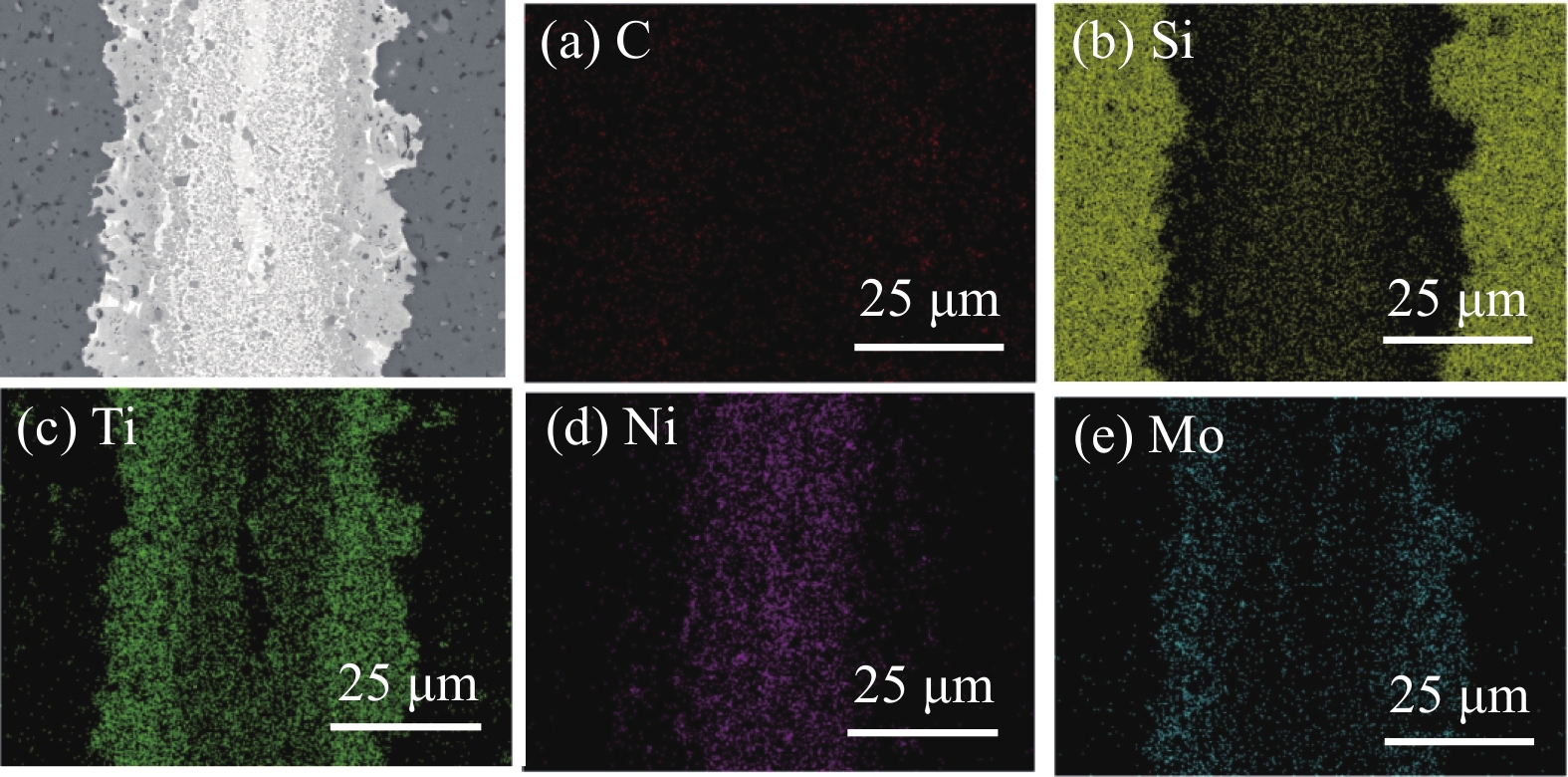

图3是接头中焊缝区域元素分布图,可以看到焊缝区域A中存在着大量的C、Ti、Mo元素,焊缝区域B中存在着大量的Ni、Si元素。C、Ti和Mo元素在焊缝两侧的富集表明可能在区域A生成Ti-Mo-C化合物;Ni和Si元素在焊缝中心的富集表明可能在区域B生成了Ni-Si化合物。

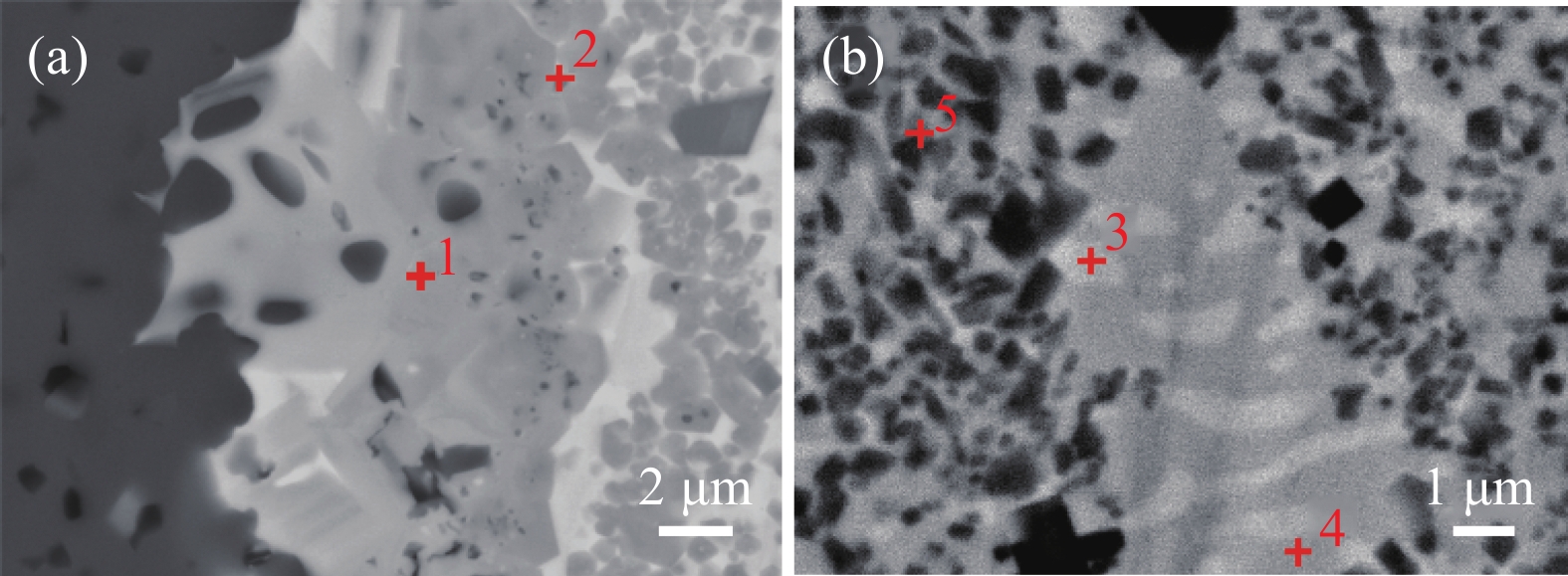

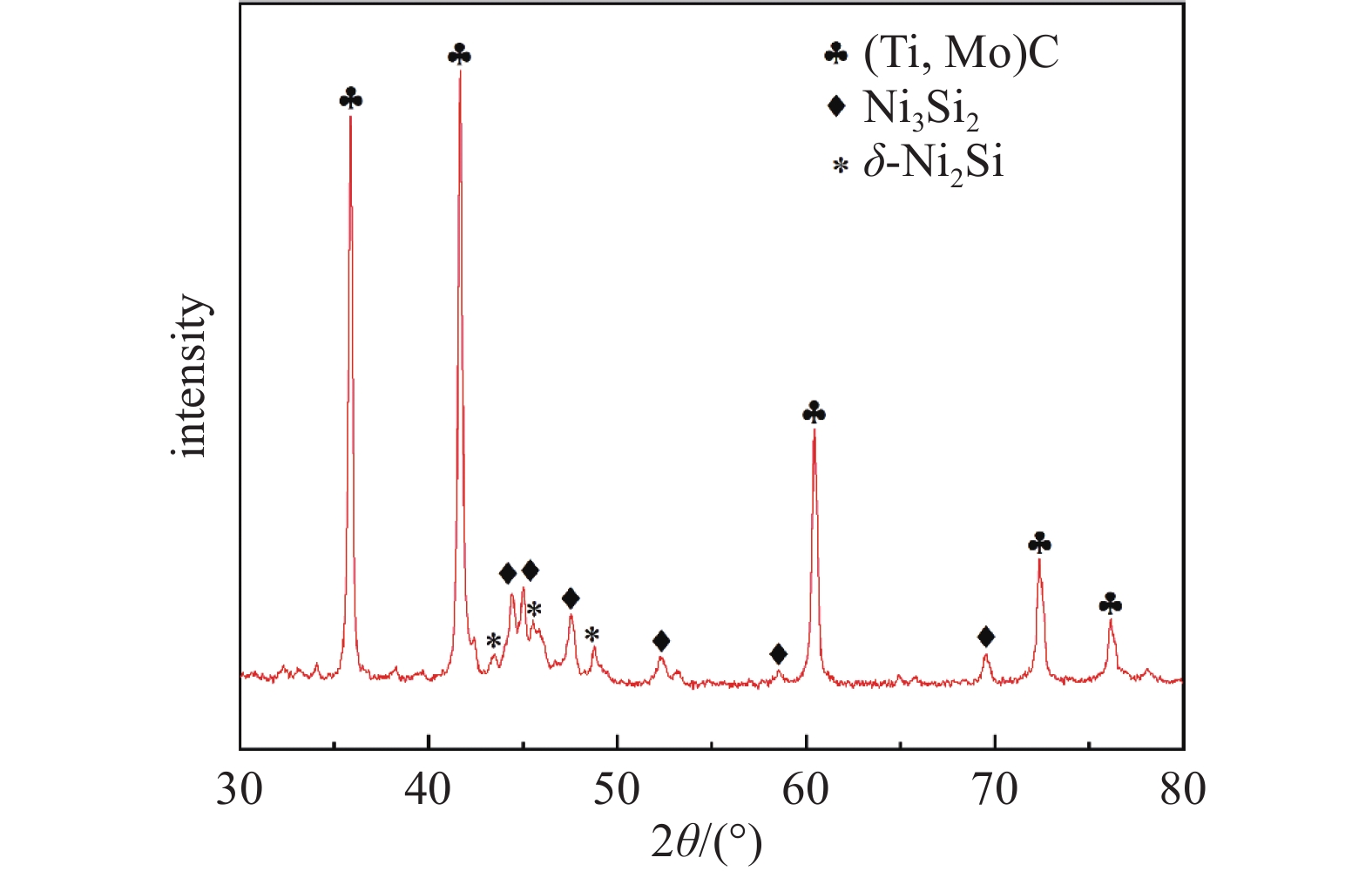

为了探究焊缝中微观组织,观察焊缝界面反应区和焊缝中心区的形貌,如图4所示。在界面反应区存在两种大量的颗粒相(标记为点1和点2);在焊缝中心区有两种不同衬度的相(标记为点3和点4)和一些颗粒相(标记为点5)。根据表1的EDS数据和图5的XRD图谱看,在区域A和区域B中的颗粒相(点1、点2和点5)为(Ti,Mo)C相,即区域中黑色、灰色颗粒相都为(Ti,Mo)C相,但由于放大倍数过大,在标定的时候有些许偏差导致点5的其他元素过高。区域B内存在两种不同衬度的相,分别为δ-Ni2Si相(标记为点3)和Ni3Si2相(标记为点4)。

-

随着界面反应的进行,母材中大量的Si元素和C元素向焊缝扩散,Si元素与液态钎料中的Ni元素发生反应,生成Ni-Si化合物[9-10];当C元素与液态钎料中的Ti元素反应时,会生成TiC[11-12],Mo没有直接参与反应,而是取代了部分Ti原子,生成碳化物(Ti,Mo)C相[13-14],在界面反应区形成了(Ti,Mo)C层。随着时间的推移,界面反应区逐渐增厚,最终达到约10 μm,阻碍了母材与液相中元素之间的扩散。随着温度的降低,液相中先析出亚稳态θ-Ni2Si相[15-16],然后θ-Ni2Si相再通过一个共析反应生成δ-Ni2Si和Ni3Si2组织[7],该组织为共析组织。

-

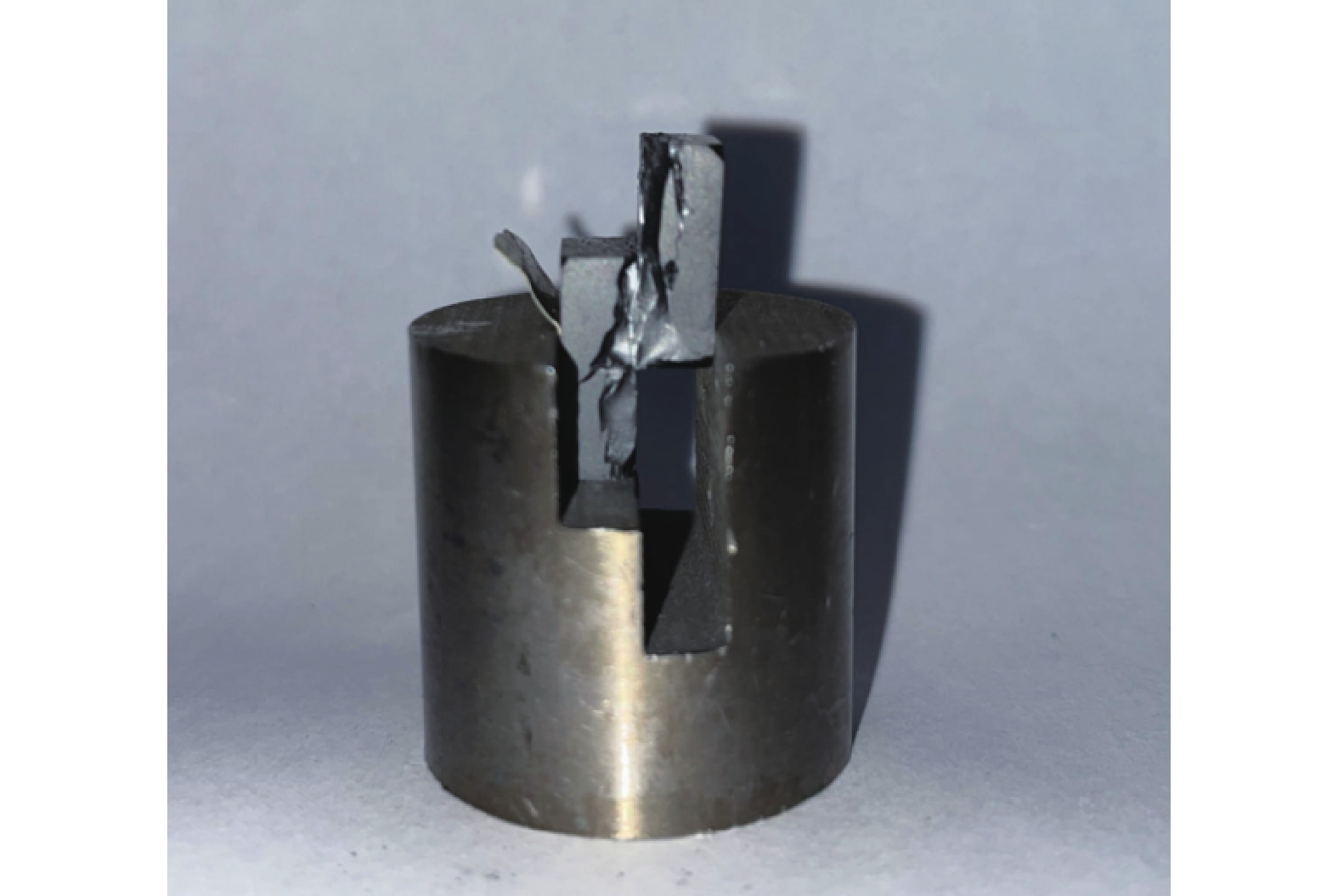

将Ni-Ti-Mo钎料制备的SiC接头进行剪切实验,接头的剪切强度如表2所示,平均剪切强度为176 MPa。虽然母材SiC和界面处组织的热膨胀系数不一样,存在残余应力,但是断裂方式为母材断裂,如图6所示,这表明连接材料与SiC陶瓷之间有良好的结合力[17]。在完全弹性的条件下,残余应力可由式(1)[18]计算:

其中E是弹性模量(GPa),下标i和j分别表示两侧的母材,α和热膨胀系数线性相关。焊缝中心区生成了δ-Ni2Si和Ni3Si2相,两种Ni-Si相的热膨胀系数(10−15×10−6 k−1[19])与母材SiC陶瓷相差过大(热膨胀系数为4.4×10−6 k−1[20]),界面反应区生成了热膨胀系数与SiC陶瓷接近的TiC (热膨胀系数为7.4×10−6 k−1)和MoC(热膨胀系数为5.6×10−6 k−1)的固溶体(Ti,Mo)C相。根据式(1)可知,接头内各相的热膨胀系数差值越小,残余应力水平也越低。因此,界面反应区生成的(Ti,Mo)C相缓解了接头的残余应力,有效提高了接头的连接强度。

和刘自豪等[6]使用NiTi基钎料连接SiC陶瓷得到的接头对比,剪切强度提高了约41%,区别在于本研究使用的是含Mo的NiTi基钎料。而Mo的热膨胀系数(4.8×10−6 k−1)接近于SiC陶瓷,使得焊缝中生成了大量的(Ti,Mo)C相,降低了残余应力;Mo的固溶会导致晶格畸变,从而引起固溶强化效应,固溶强化提高材料的硬度和强度;Mo的加入可能会影响TiC的晶粒生长过程,导致晶粒细化,晶粒越细,材料的强度越高[21]。

-

(1)采用Ni-Ti-Mo钎料成功实现了SiC陶瓷的有效连接,钎焊工艺在1350℃下保温10 min,焊缝致密、连续且无明显孔洞。焊缝两侧界面反应区组织为(Ti,Mo)C,焊缝中心区组织为大量的颗粒状(Ti,Mo)C相、δ-Ni2Si相和Ni3Si2相。

(2)对Ni-Ti-Mo钎料连接的SiC陶瓷接头进行剪切强度测试。结合计算残余应力的公式和测试结果可知,由于焊缝中生成了低热膨胀系数的大量颗粒状(Ti,Mo)C相,降低了接头的残余应力。SiC陶瓷接头的平均强度为176±17 MPa,且断裂方式为母材断裂。

Ni-Ti-Mo钎料连接SiC陶瓷的微观组织与性能研究

Microstructure and Properties of SiC Ceramics Connected by Ni-Ti-Mo Filler

-

摘要: 为了缓解SiC陶瓷钎焊接头中的残余应力,提高接头的室温力学性能,采用Ni-Ti-Mo钎料来连接SiC陶瓷。结果表明:SiC/Ni-Ti-Mo/SiC接头结合良好,焊缝致密无孔洞。接头由界面反应区和焊缝中心区两个区域组成,界面反应区的微观组织为(Ti,Mo)C相,焊缝中心区的微观组织为Ni2Si和Ni3Si2以及大量的(Ti,Mo)C颗粒。接头中大量生成的(Ti,Mo)C相与SiC陶瓷母材的热膨胀系数相近,能降低接头的残余应力,提高了接头的力学性能。接头的平均室温剪切强度达为176±17 MPa,且断裂方式为母材断裂。

-

关键词:

- 钎焊 /

- Ni-Ti-Mo钎料 /

- SiC陶瓷 /

- 力学性能 /

- 热膨胀系数

Abstract: To alleviate the residual stress in SiC ceramic brazing joints and enhance their mechanical properties at room temperature, a Ni-Ti-Mo brazing filler was employed to join SiC ceramics. The results demonstrate that the SiC/Ni-Ti-Mo/SiC joint exhibits excellent bonding, with a dense and pore-free weld. The joint consists of two distinct regions: the interface reaction area and the weld center area. The microstructure of the interface reaction area is characterized by the (Ti, Mo)C phase, while the weld center area comprises Ni2Si and Ni3Si2 phases, along with a significant amount of (Ti, Mo)C particles. The (Ti, Mo)C phase, which is extensively formed in the joint, has a thermal expansion coefficient similar to that of the SiC ceramic base material. This reduces the residual stress of the joint and improves its mechanical properties. The average shear strength of the joints is 176 MPa at room temperature, with fractures occurring within the base metal.-

Key words:

- Brazing /

- Ni-Ti-Mo filler /

- SiC ceramics /

- Mechanical properties /

- Coefficient of thermal expansion .

-

-

表 1 焊缝中各点组分分析结果(原子分数/%)

Table 1. Composition analysis results of each point in the weld seam (/%)

点 C Si Ti Ni Mo 可能的相 1 57.98 2.01 34.28 0.72 5.01 (Ti,Mo)C 2 58.18 2.27 35.47 1.05 3.03 (Ti,Mo)C 3 38.56 20.62 2.86 37.46 − δ-Ni2Si 4 28.93 27.24 1.92 41.16 0.19 Ni3Si2 5 49.54 11.08 22.51 12.39 4.24 (Ti,Mo)C 表 2 SiC钎焊接头的剪切强度

Table 2. Shear strength of SiC brazing joints

接头

编号试样1 试样2 试样3 试样4 平均剪切强度 剪切强度/MPa 160 203 176 165 176±17 -

[1] Li Z, Wei R, Wen Q, et al. Microstructure and mechanical properties of SiC ceramic joints vacuum brazed with in-situ formed SiC particulate reinforced Si-24Ti alloy[J]. Vacuum,2020,173:109160 doi: 10.1016/j.vacuum.2019.109160 [2] Shi H, Peng H, Chai Y, et al. Effect of Zr addition on the interfacial reaction of the SiC joint brazed by Inconel 625 powder filler[J]. Journal of the European Ceramic Society,2021,41(13):6238−6247 doi: 10.1016/j.jeurceramsoc.2021.06.047 [3] Wu J, Yan J, Peng H, et al. Reaction mechanism and mechanical properties of SiC joint brazed by in-situ formation of Ti3SiC2[J]. Journal of the European Ceramic Society,2024,44(6):3777−3783 doi: 10.1016/j.jeurceramsoc.2023.12.097 [4] Li H X, Zhong Z H, Zhang H B, et al. Microstructure characteristic and its influence on the strength of SiC ceramic joints diffusion bonded by spark plasma sintering[J]. Ceramics International,2018,44(4):3937−3946 doi: 10.1016/j.ceramint.2017.11.185 [5] Ming A, Li C, Liu Y, et al. Understanding the oxidation behavior of TiAl alloy joints brazed using Ti and Ni based filler[J]. Journal of Materials Research and Technology,2024,28:2033−2044 doi: 10.1016/j.jmrt.2023.12.040 [6] 刘自豪, 颜家振, 李宁, 等. NiTi+Ni钎料真空钎焊SiC陶瓷的微观组织及性能[J]. 热加工工艺,2023,52(19):20−23 (in Chinese) Liu Z H, Yan J Z, Li N, et al. Microstructure and properties of vacuum brazing SiC ceramics with NiTi+Ni filler[J]. Hot Working Technology,2023,52(19):20−23 [7] Kamal A, Shukla A K, Shinde V M, et al. Effect of Mo addition on interfacial microstructure and mechanical property of SiC joint brazed by an Ni-Si filler[J]. Journal of the American Ceramic Society,2024,107(5):2861−2876 doi: 10.1111/jace.19677 [8] Wang Z, Liu Y, Zhang H, et al. Joining of SiC ceramics using the Ni-Mo filler alloy forheat exchanger applications[J]. Journal of the European Ceramic Society,2021,41(15):7533−7542 doi: 10.1016/j.jeurceramsoc.2021.07.056 [9] 王子康, 刘岩, 杨金晶, 等. Ni基高温钎料连接SiC陶瓷的微观结构和力学性能[J]. 焊接,2023(2):8−16 (in Chinese) doi: 10.12073/j.hj.20220429005 Wang Z K, Liu Y, Yang J J, et al. Microstructure and mechanical properties of SiC/SiC joints brazed with Ni-based high-temperature filler[J]. Welding & Joining,2023(2):8−16 doi: 10.12073/j.hj.20220429005 [10] Shi H, Chai Y, Li N, et al. Interfacial reaction mechanism of SiC joints joined by pure nickel foil[J]. Journal of the European Ceramic Society,2020,40(15):5162−5171 doi: 10.1016/j.jeurceramsoc.2020.07.048 [11] He H, Lu C, He Y, et al. Characterization of sic ceramic joints brazed using Au-Ni-Pd-Ti high-temperature filler alloy[J]. Materials,2019,12(6):931 doi: 10.3390/ma12060931 [12] Leinenbach C, Transchel R, Gorgievski K, et al. Microstructure and mechanical performance of Cu-Sn-Ti-based active braze alloy containing in situ formed nano-sized TiC particles[J]. Journal of materials engineering and performance,2015,24(5):2042−2050 doi: 10.1007/s11665-015-1471-8 [13] Deng X, Cui J, Zhang G. Effects of TiC powder characteristics and sintering temperature on the microstructure and mechanical properties of TiC-20Mo-10Ni cermets[J]. Metallurgical and materials transactions. A, Physical metallurgy and materials science,2023,54(12):4940−4951 doi: 10.1007/s11661-023-07215-5 [14] 王兴, 成来飞, 范尚武, 等. Cu-Ti+Mo连接2D C/SiC复合材料与GH783的接头微结构与性能[J]. 稀有金属材料与工程,2012,41(09):1544−1548 (in Chinese) doi: 10.3969/j.issn.1002-185X.2012.09.009 Wang X, Cheng L F, Fan S W, et al. Microstructure and properties of 2D C/SiC composite/GH783 joint brazed with Cu-Ti+Mo composite filler[J]. Rare Metal Materials and Engineering,2012,41(09):1544−1548 doi: 10.3969/j.issn.1002-185X.2012.09.009 [15] Tellouche G, Mangelinck D, Hoummada K, et al. Further insights into the growth mechanism of the non-stoichiometric θ-Ni2Si phase[J]. Vacuum,2021,187:110075 doi: 10.1016/j.vacuum.2021.110075 [16] Panciera F, Mangelinck D, Hoummada K, et al. Direct epitaxial growth of θ-Ni2Si by reaction of a thin Ni(10at.% Pt) film with Si(100) substrate[J]. Scripta Materialia,2014,78-79:9−12 doi: 10.1016/j.scriptamat.2014.01.010 [17] Zhong Z, Hou G, Zhu Z, et al. Microstructure and mechanical strength of SiC joints brazed with Cr3C2 particulate reinforced Ag-Cu-Ti brazing alloy[J]. Ceramics International,2018,44(10):11862−11868 doi: 10.1016/j.ceramint.2018.04.002 [18] Peteves S D, Nicholas M G. Evaluation of brazed silicon nitride joints: microstructure and mechanical properties[J]. Journal of the American Ceramic Society,1996,79(6):1553−1562 doi: 10.1111/j.1151-2916.1996.tb08764.x [19] Tian W B, Sun Z M, Zhang P, et al. Brazing of silicon carbide ceramics with Ni-Si-Ti powder mixtures[J]. Journal of the Australian Ceramic Society,2017,53(2):511−516 doi: 10.1007/s41779-017-0061-7 [20] Ma Q, Chen Y W, Chen S J, et al. Microstructural and mechanical characterizations of SiC-304SS joints brazed with Cu-10TiH2 filler[J]. Journal of Materials Research and Technology,2024,28:3076−3083 doi: 10.1016/j.jmrt.2023.12.226 [21] Zhang G , Xiong W , Yang Q , et al. Effect of Mo addition on microstructure and mechanical properties of (Ti, W)C solid solution based cermets[J]. International Journal of Refractory Metals & Hard Materials, 2014, 43: 77−82 -

首页

首页 登录

登录 注册

注册

下载:

下载: