-

热管作为高效的换热元件之一,它能够通过工质相变将热量有效远距离传输。根据工作温度的不同,将热管分为低温、中温和高温热管。高温热管的工作温度可以达到600~1800 K,因其均温性好和运行效率高等优点而在石油化工、太阳能热利用、航空航天和核工程等领域有着广泛的应用[1,2]。由于高温热管常采用的碱金属工质(如钠、钾、锂和铯等)在室温下一般为固态,使得高温热管从“冻结状态”下启动过程中易出现蒸发段烧干而冷冻启动失败的现象[3],会对热管本身及系统运行产生不良后果。因此,冷冻启动性能一直是国内外学者研究高温热管性能的一个重要方向。

一些学者考察了热管结构和操作条件对高温热管启动性能的影响规律,如赵蔚琳[4]考察了充液量对钠热管启动过程的影响,发现充液量过多和过少都会影响钠热管的启动性能,同时发现蒸发段长度太短会导致钠热管启动失败。贾先剑等[5]在水冷条件下实验研究了加热温度为573~923 K时钠钾合金热管的启动性能,结果表明,加热温度在573~823 K时钠钾合金热管无法启动,在873 K和923 K时才能顺利启动。可见,高温热管蒸发段的加热温度需足够高才能顺利启动,过低则无法启动。此外,热管内的吸液芯既是液体工质流动的通道,还为液体工质回流提供毛细力。因此,吸液芯的存在对高温热管的启动性能有着重要的影响。如韩冶等[6]实验对比分析了钾热管丝网芯结构和无芯结构下的的启动性能,发现有芯结构的启动性能优于无芯结构的。

传统吸液芯结构主要有丝网型、金属粉末烧结型和槽道型,但是各有优劣。丝网型吸液芯结构简单,制造方便,但丝网与管壁贴合不紧会导致热阻较大[7]。槽道型吸液芯径向热阻小但能提供的毛细力小而性能易受工作倾角影响[8]。金属粉末烧结型吸液芯热阻较小且毛细力大,但是孔隙率低导致了冷凝液回流阻力大,一些学者探究了烧结粉末粒径和几何形状对热管孔隙率和毛细性能的影响[9],且通过可视化的方法观察到烧结金属芯多孔柱有效改善了热管传热性能[10]。为了使吸液芯能同时兼具高毛细抽力、低流动阻力及强传热性能的优点,一些学者提出了对多种单一结构进行组合的复合式吸液芯[11-13]。白穜等[14]实验发现热管的吸液芯由金属纤维毡和三角沟槽组合后其传热性能优于三角沟槽的。研究表明,复合式吸液芯受单一吸液芯种类、孔径结构和大小等诸多因素影响[15],目前尚未获得具体的影响规律。因此,对于传统吸液芯的研究较为充分,而对综合性能优良的新型吸液芯结构尚需开发和研究。

泡沫金属材料因具有高比表面积、高渗透性能、高机械强度和低密度等优点深受研究人员青睐,并在建筑节能、高效电子冷却和航天航空等领域得到了广泛应用[16,17]。一些学者发现通孔泡沫金属中的无规则多孔结构不仅能提供大量汽化核心强化沸腾传热,驱动气泡快速生长,还可以使流场均匀化[18-20],在降低过热度、强化沸腾传热方面具有较大的潜力。研究发现,将泡沫金属作为热管吸液芯具有毛细抽力高、渗透率高、液体工质流动阻力小、导热性能好和组装方便等优点。郑丽等[21]实验研究表明,由于泡沫镍吸液芯产生的最大毛细力比丝网芯大且有效热导率高,泡沫镍吸液芯水热管比不锈钢丝网吸液芯的具有更好的启动性能,其启动时间缩短了30 min。姚寿广[22]通过对泡沫铜吸液芯纳米流体热管的传热性能与丝网芯的进行对比实验研究,发现泡沫金属芯的传热系数大,总热阻小,最大传输功率比丝网芯的高。因此,将泡沫金属吸液芯应用于高温热管中对提高其工作性能和促进其应用发展具有较大潜力。本文研制了泡沫金属芯钠热管,并进行了初步的实验研究,探究加热温度对泡沫金属芯钠热管启动性能的影响。

-

高温热管冷冻启动过程中管内工质的流态经历三种状态,即自由分子流、过渡流和连续流,可通过无量纲Knudsen数来定义。通常,当Kn>1时,工质流态为自由分子流;当0.01<Kn<1时,工质流态处于自由分子流至连续流转变的过渡流;当Kn<0.01时,工质流态为连续流。Kn=1和Kn=0.01所对应的温度分别为流态由自由分子流向过渡流、过渡流向连续流转变的温度。

不考虑分子间的引力,认为蒸汽分子为刚性小颗粒,通过Maxwell理论推导可得Knudsen数:

式中:λ为分子平均自由程,m;D为热管蒸汽腔直径,m;ps为转变温度Ttr时工质饱和蒸汽压,Pa;k为Boltzman常数,k=1.38×10−23 J/K;σ为工质有效分子直径,m;Ttr为蒸汽温度,K。

将热管工质的物性参数代入式(1)进行迭代计算,可获得工质在不同流态下的转变温度。本文研制的泡沫金属芯钠热管蒸汽腔直径为26 mm,管内工质过渡态和连续流态转变温度分别为268℃和413℃。无芯钠热管蒸汽腔直径为30 mm,管内工质过渡态和连续流态转变温度分别为266℃和407℃。

-

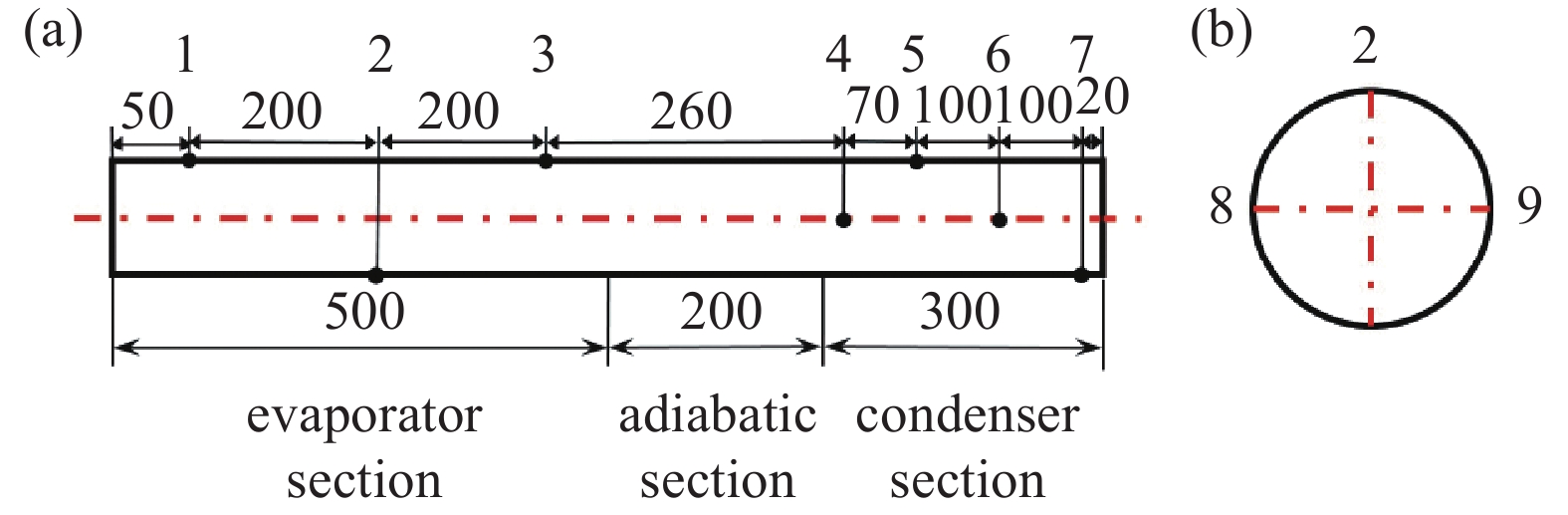

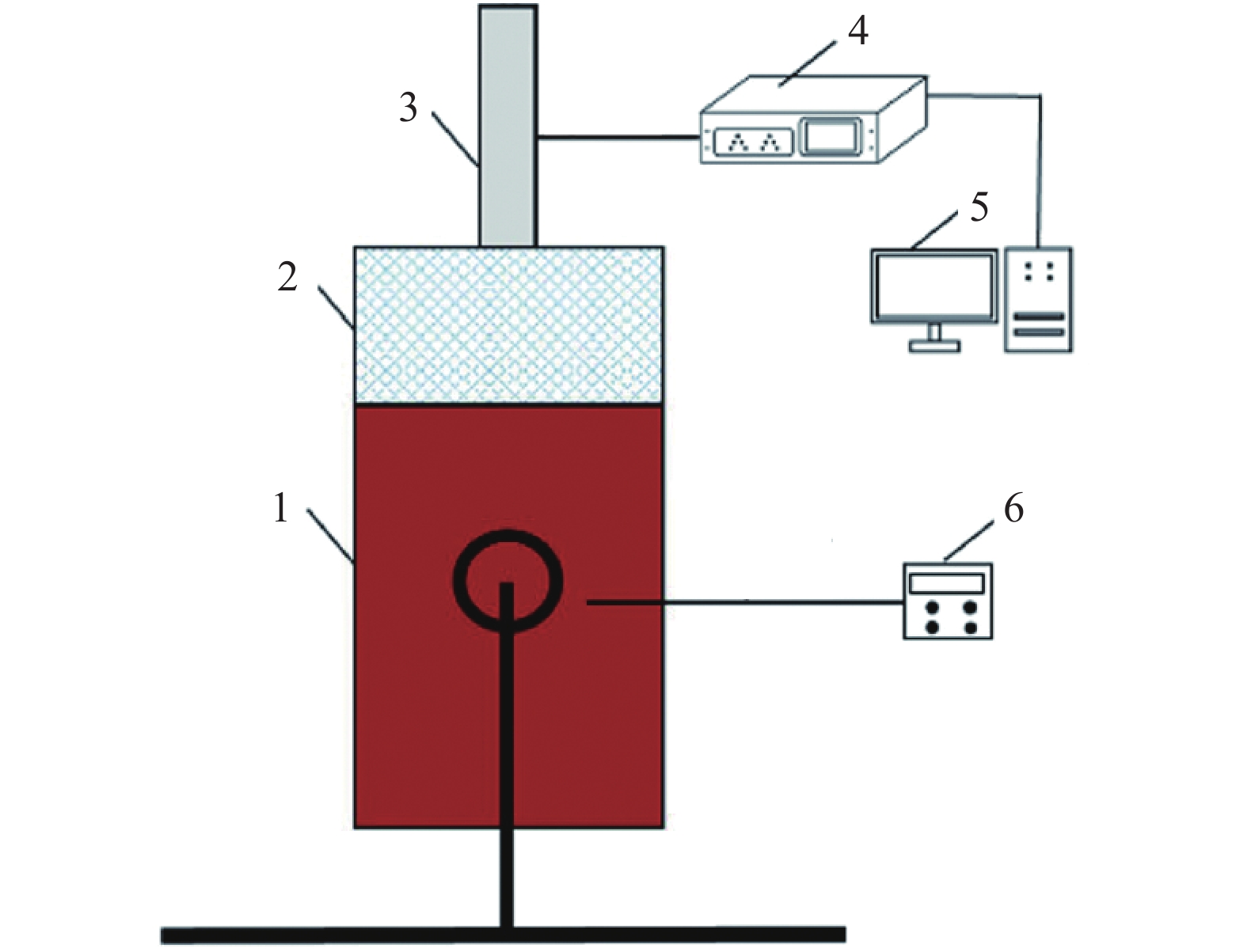

本文研究对象为泡沫金属芯钠热管,制造了相同尺寸的无芯钠热管以进行性能对比。热管管材为310s不锈钢,外径为34 mm,壁厚为2 mm,总长为1000 mm,蒸发段长500 mm,绝热段长200 mm,冷凝段长300 mm。工质钠约71 g。泡沫金属芯钠热管选用厚度2 mm、孔隙率97%的泡沫镍作为吸液芯。图1为高温热管实验测试系统示意图。实验系统主要由高温热管、加热炉和数据采集系统三部分组成。加热炉为管式硅碳棒加热炉,通过温控仪来调节加热炉的加热温度。实验中高温热管呈蒸发段在下而冷凝段在上的竖直放置,蒸发段置于加热炉内;绝热段由硅酸铝保温棉包裹,以此减少热量散失;冷凝段暴露在空气中自然冷却。

热管壁面温度通过K型铠装热电偶和温度巡检仪进行数据采集。图2为热管壁面热电偶分布图。热管壁面沿轴向布置了7 根K 型热电偶,其中蒸发段3 根,冷凝段4 根;沿周向在蒸发段布置了3 根热电偶。在实验加热功率为711~1429 W时,据热管管壁厚度和不锈钢导热系数计算得出,热管管壁内外温差在2~4 K,相较于管内蒸汽流转变温度可忽略,故本文以所测壁温来代表热管内蒸汽温度。

K型热电偶的误差为±2.5℃(测量范围为0℃~300℃)和±0.0075t℃(测量范围为300℃~1100℃),t为被测温度实际值。本实验中,测量热管壁面的温度范围为20℃~960℃,故测试中产生的误差限最小值为±0.75%,最大值为±12.5%。

-

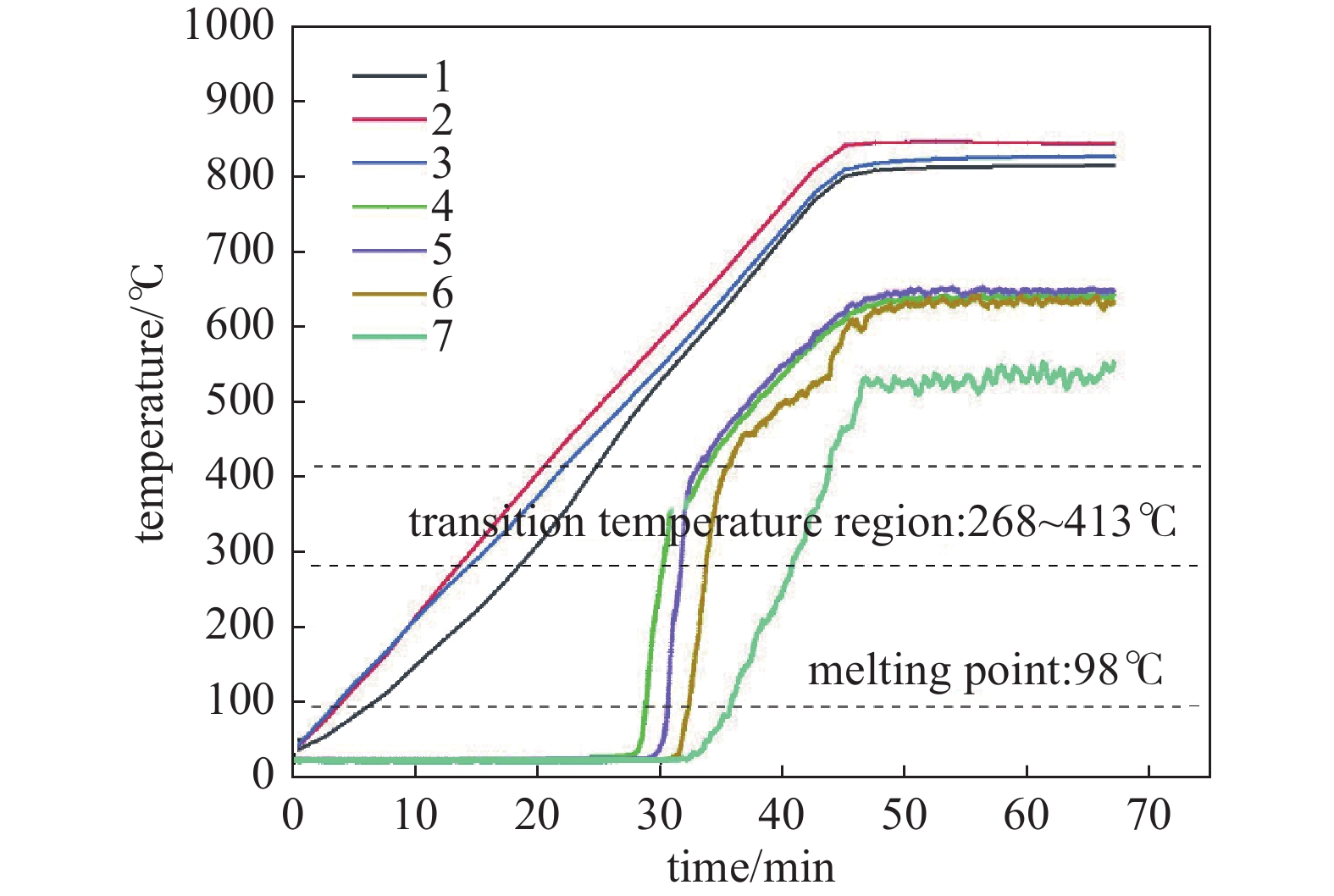

图3和图4分别为泡沫金属芯钠热管在加热温度850℃下的温升曲线和轴向温度分布图。

从图3和图4可以看出,随着加热的进行,泡沫金属芯钠热管的蒸发段温度从室温迅速上升,热管工质钠在约5 min时开始融化,10 min左右从固态全部熔化成液态。在20 min左右,蒸发段壁面温度在268℃之上,说明蒸发段中钠蒸汽已全部由自由分子流转变为过渡流。在25 min左右蒸发段壁面温度升至413℃,说明蒸发段中的钠蒸汽已处于连续流动状态,热管蒸发段温度受炉温影响升温过程较为稳定,升温曲线较为平滑[23];而此时冷凝段还处于常温,说明钠蒸汽还未流动至冷凝段。在40 min左右,冷凝段壁面温度在268℃,说明此时冷凝段中钠蒸汽从自由分子流转变为过渡流。在45 min左右,冷凝段壁面温度升至413℃,温升趋势变缓,说明冷凝段中的钠蒸汽也已全部处于连续流状态,此时整个热管完全启动。

通过图3可以发现,泡沫金属芯钠热管冷凝段测点4的温度在32 min时开始低于测点5的温度。究其原因,热管蒸发段在加热温度较高时瞬间产生大量低密度钠蒸汽,且越靠近蒸发段出口钠蒸汽质量流量越大,但受热管管径的约束,蒸汽流速不断提高导致压力不断降低。类似于拉伐尔喷管中的收缩段,此时管内工质为气液两相共存状态,蒸汽的温度受饱和压力的影响,压力降低,温度也随之降低。在冷凝段中,越靠近冷凝段顶端,蒸汽质量流量越小,流速不断降低导致压力回升,温度回升,从而出现测点4的值低于测点5的现象。但是随着加热的进行,泡沫金属芯钠热管冷凝段的温度随之持续上升,说明热管未达到声速极限,此时热管内部蒸汽流处于亚声速流状态[24]。

-

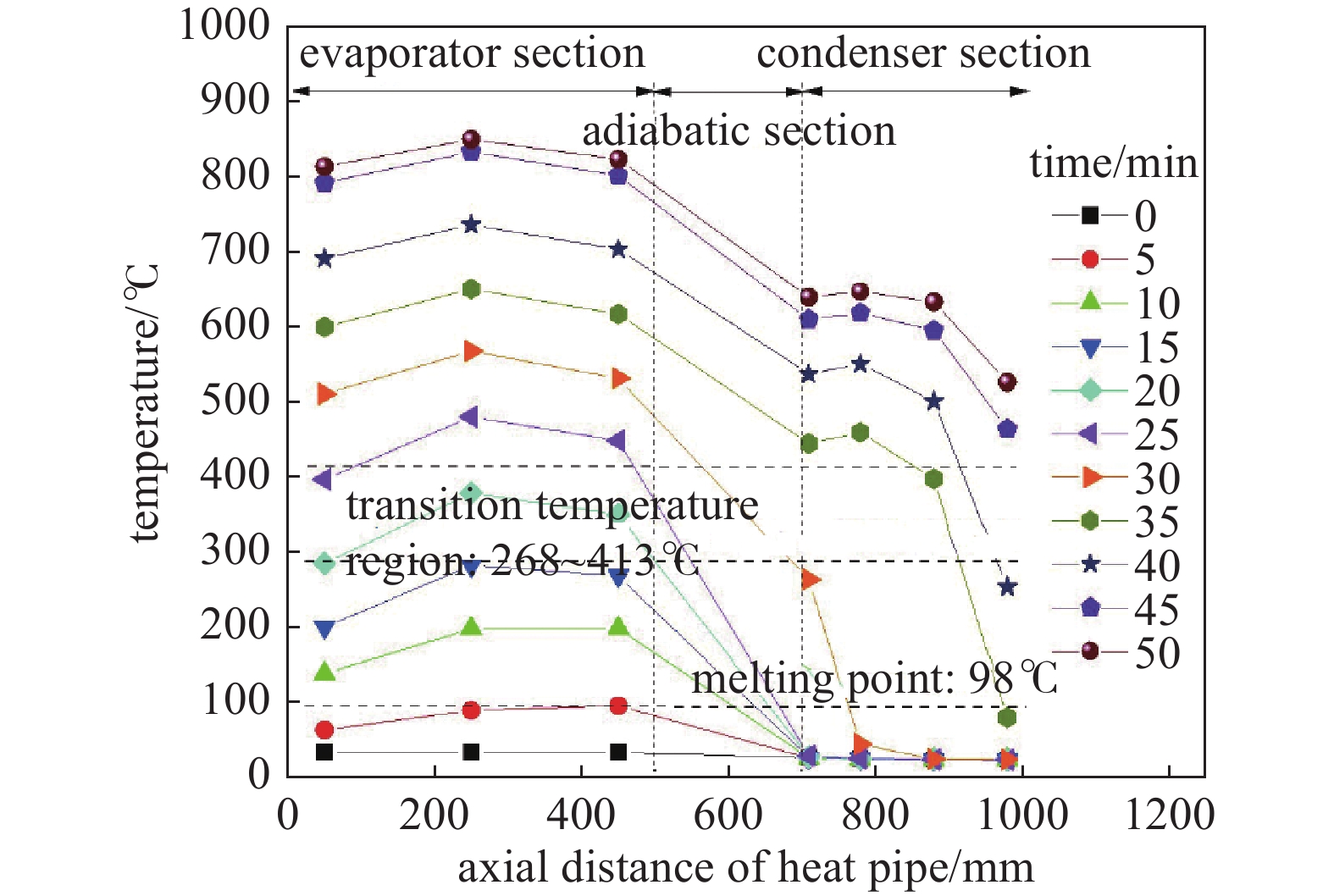

图5为不同加热温度下泡沫金属芯钠热管和无芯钠热管的冷凝段顶端测点7测温值随时间的变化。

从图5可以看出,泡沫金属芯钠热管加热温度为750℃时、无芯钠热管加热温度为750℃和800℃时,热管测点7温度稳定后未达到连续流转变温度点,说明热管未能成功启动。这是由于蒸发段加热温度低,输入热量不足,无法维持工质持续升温达到连续流。随着加热温度的增加,测点7达到稳态时的温度不断升高,热管启动性能逐渐改善。泡沫金属芯钠热管在加热温度为800℃~950℃时成功启动,无芯钠热管则在850℃~950℃时成功启动,且两根热管蒸发段加热温度越高,冷凝段升温速度越快,到达连续流转变温度的时间越短,在加热温度为950℃时启动最快,启动时间分别为39 min和43 min。这是由于蒸发段加热温度的增加提高了内部工质的吸热速度,让工质可以更快达到所需温度和压力,缩短了工质吸热蒸发、冷凝放热和液体回流的时间,可更快地将热量从热管蒸发段传至冷凝段进而缩短热管的冷冻启动时间。

从图5(b)可以看出,在蒸发段加热温度处于较低水平时,无芯钠热管内部温度比较稳定;当加热温度增加到850℃和900℃时,热管启动完成后冷凝段顶端温度出现明显骤变现象,实验中可以清晰地听到管内液柱间歇性撞击冷凝段金属端面的砰砰响声,且伴随着管体剧烈振动,冷凝段末端发黑,如图6所示。而随着加热温度增至950℃,温度骤变现象消失,管内温度较为稳定。造成这种现象的原因是无芯钠热管内出现了钠工质的气液携带。当无芯钠热管内蒸汽速度够高,气液交界面存在的剪切力将吸液芯表面液体撕裂并将其带入蒸汽流冲向冷端,从而出现撞击端面的响声和温度骤变的现象[25],会导致冷凝液回流减少和传热能力的下降。而泡沫金属芯钠热管由于泡沫金属芯的存在,液体分布在泡沫金属芯中,气液分处两层,不易出现液体工质被蒸汽携带抛至冷凝段的现象。同时由于吸液芯毛细抽力的存在,液态工质在吸液芯分布较为均匀,从而有利于提高热管启动过程的稳定性。

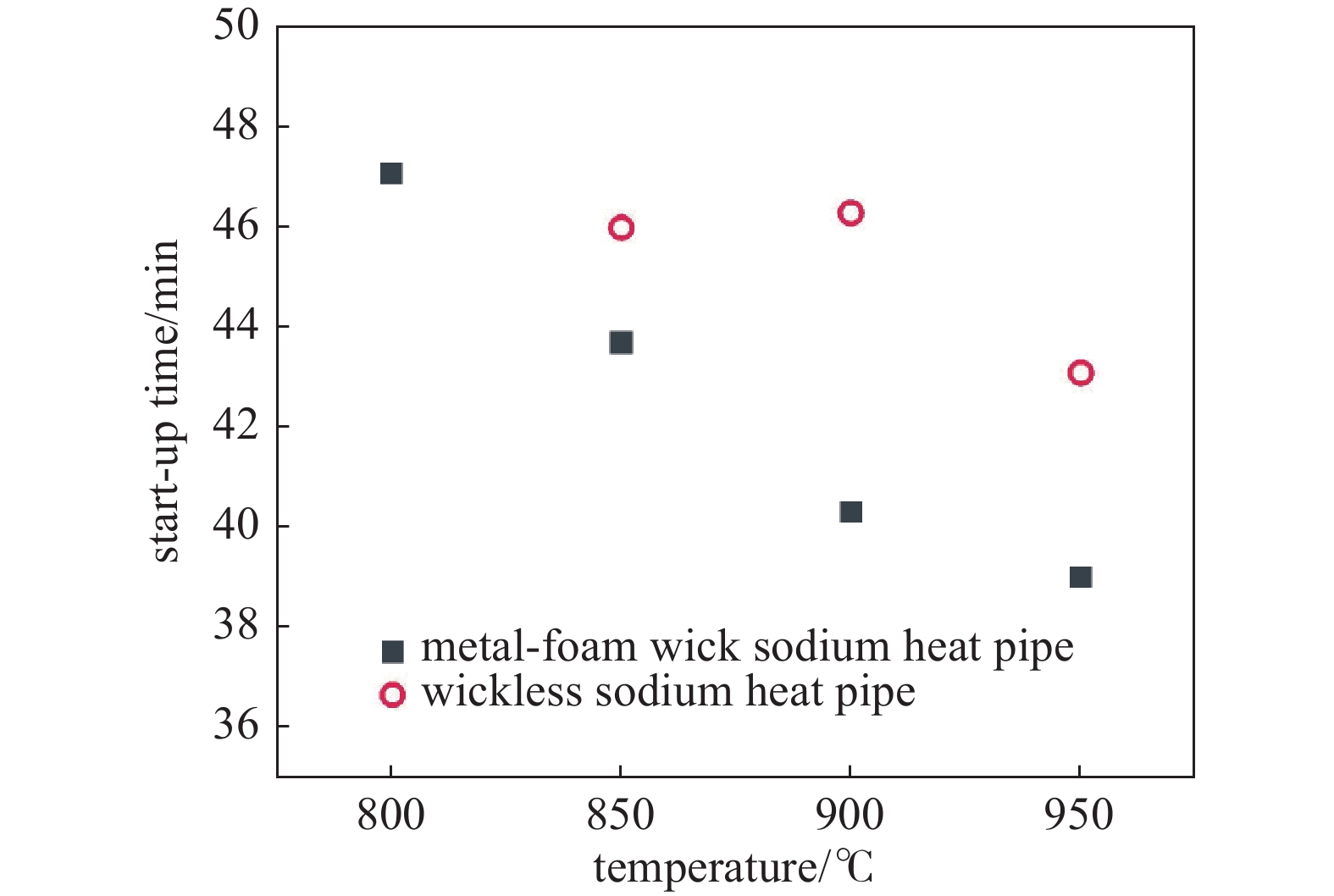

通常,以测量热管内蒸汽温度(常以壁温来代替)是否达到理论转变温度来判断热管是否启动。不同加热温度下泡沫金属芯钠热管和无芯钠热管的启动时间如图7所示。从图7中可以看出,相同加热温度下泡沫金属芯钠热管启动所需的时间比无芯钠热管要短,在加热温度850℃~950℃时的启动时间约缩短6%~11%。分析其原因,泡沫金属芯钠热管工质均布在多孔结构的吸液芯中,传热面积大,有效热导率高(约为68 W/(m·K)),能够加快轴向传热,且泡沫金属芯的多孔结构能促进液态工质的初始核化[18],较无芯钠热管能让冷凝段工质更快熔化和蒸发;同时,泡沫金属吸液芯又可为工质回流提供流动通道。因此泡沫金属芯钠热管的启动性能优于无芯钠热管。

-

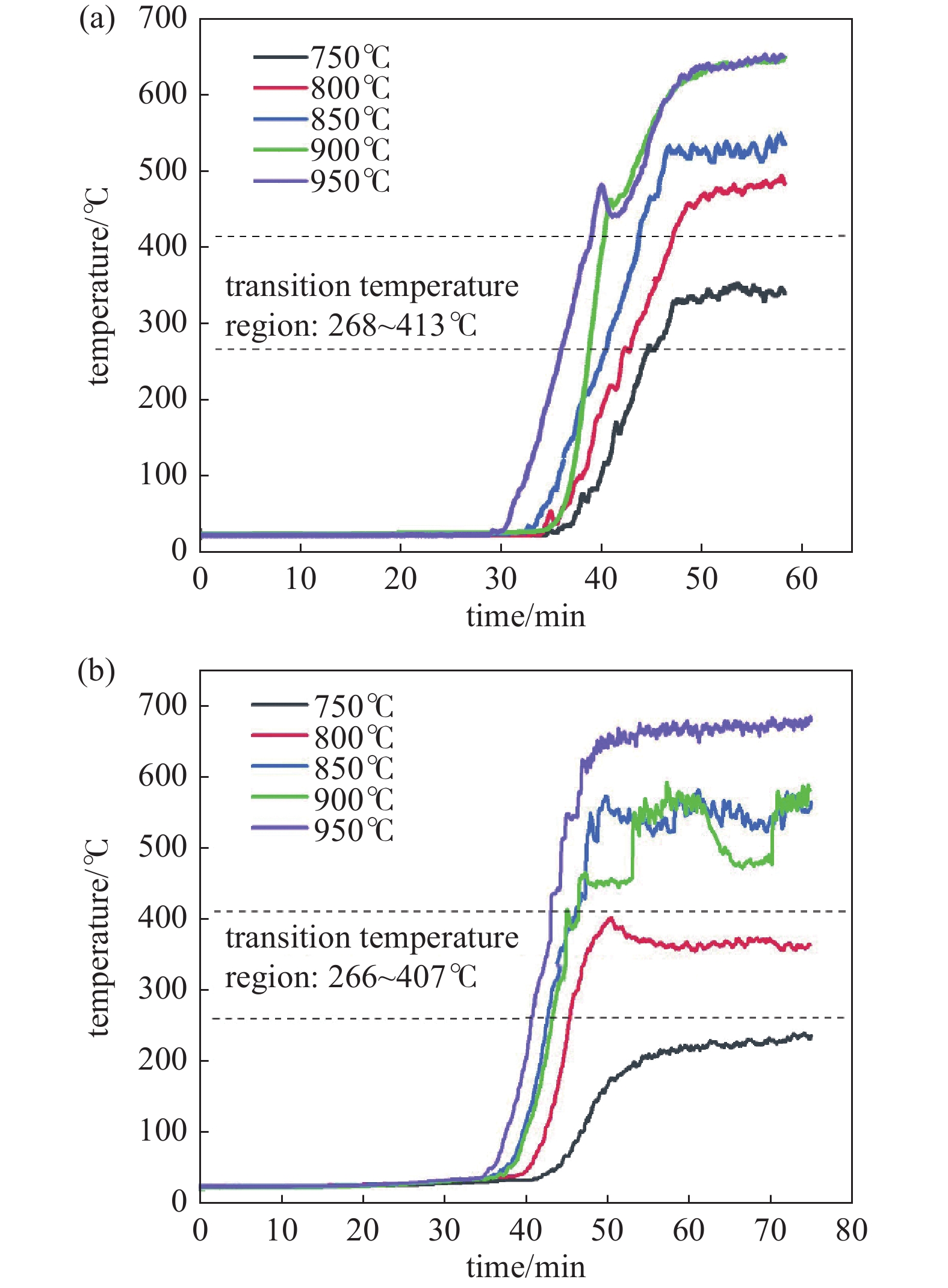

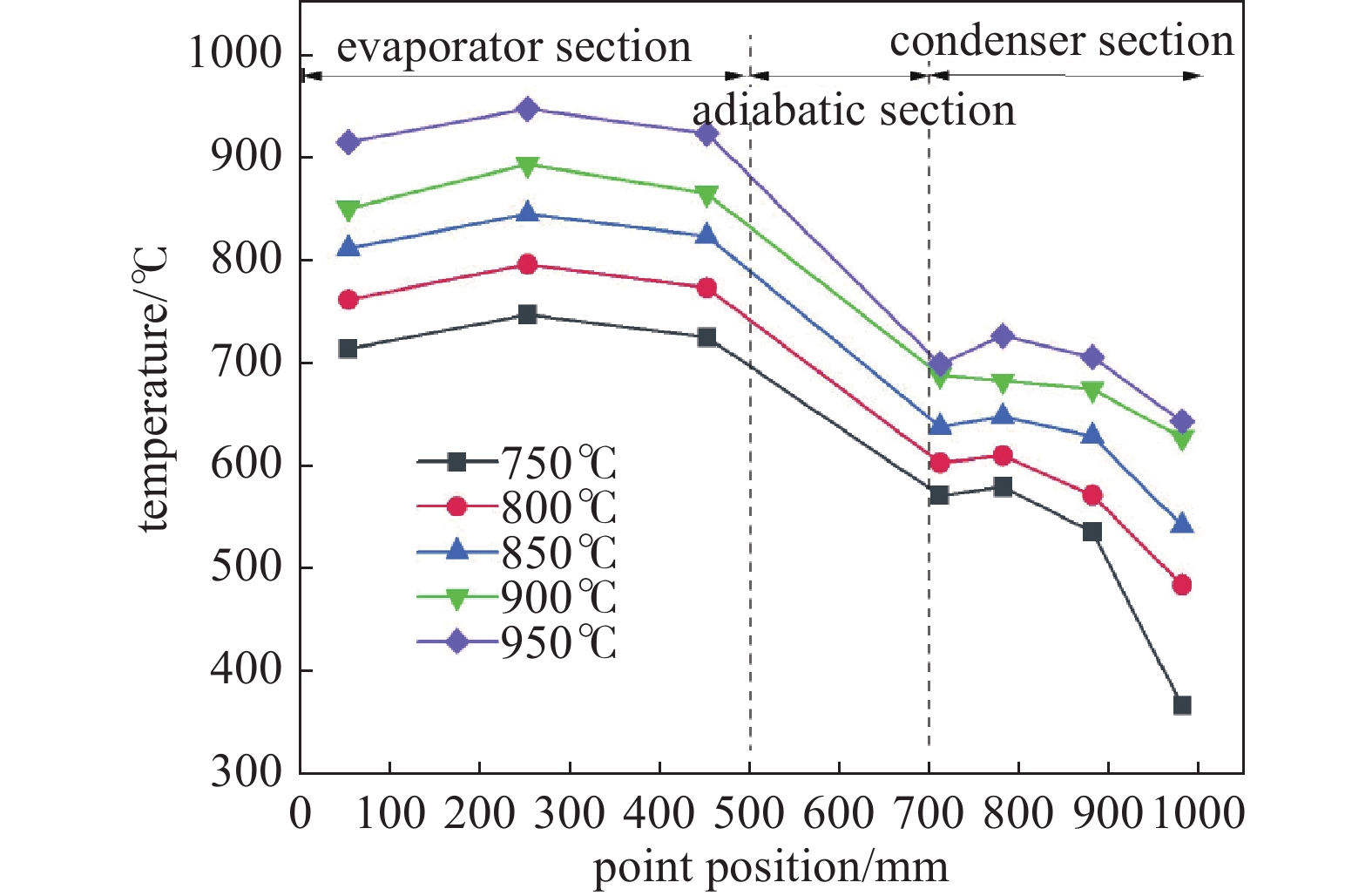

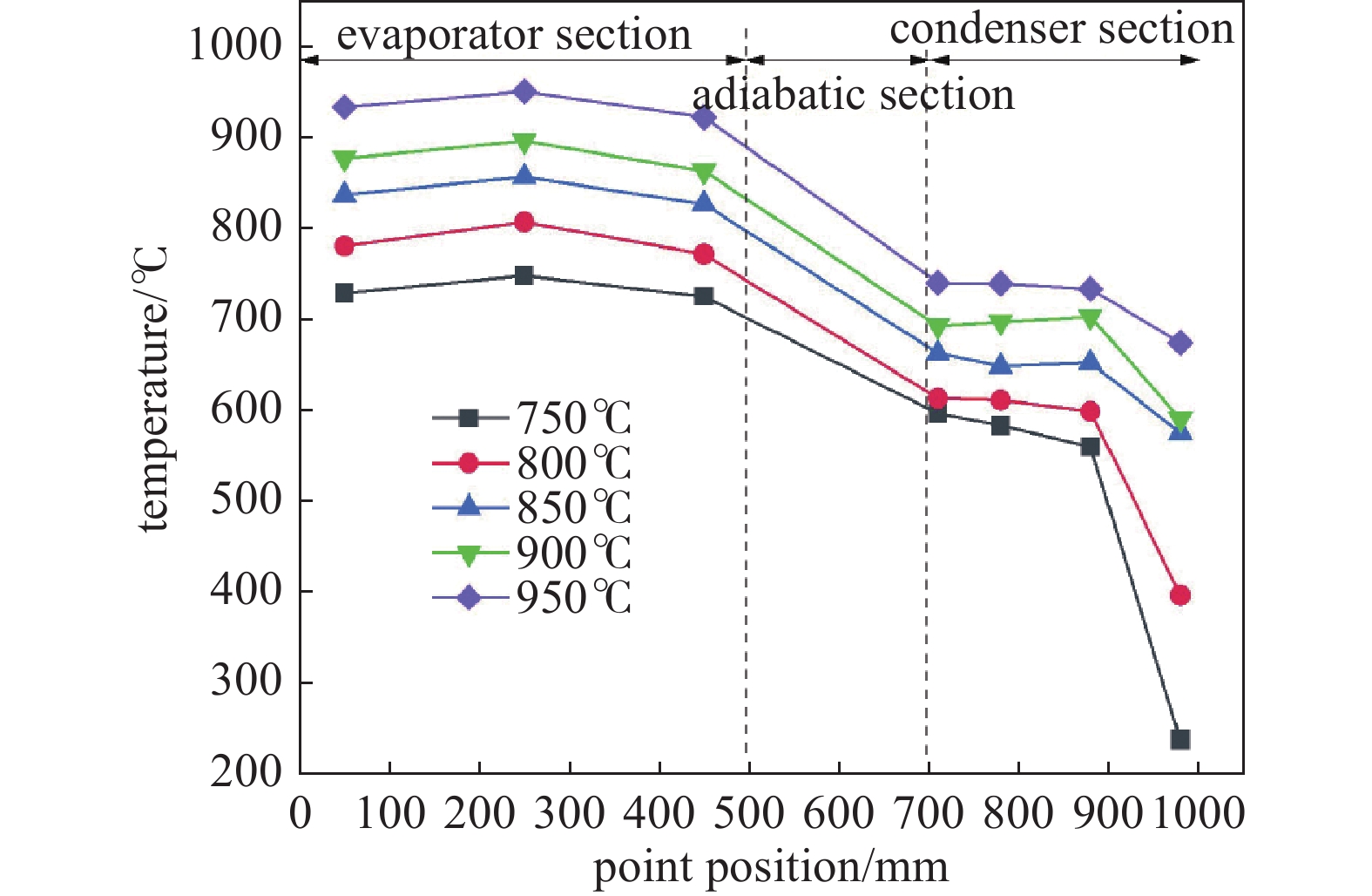

图8和图9为不同加热温度下泡沫金属芯钠热管和无芯钠热管稳态时轴向壁面温度分布图。从图8和图9可以看出,泡沫金属芯钠热管和无芯钠热管蒸发段(测点1~3)温度较高,冷凝段温度(测点4~7)较低,两根热管在加热温度750℃时均未启动,且蒸发段与冷凝段间温差较大,其中泡沫金属芯钠热管的温差为378℃,而无芯钠热管的温差高达512℃。随着蒸发段加热温度的增加,两根热管的整体温度升高,轴向温度分布越来越均匀,即均温性越来越好,如泡沫金属芯钠热管轴向温差降为265℃,而无芯的降为277℃。

分析其原因,加热温度的增加使得热管蒸发段内产生更多的饱和蒸汽而使管内蒸汽压力增大、快速推动饱和蒸汽运动至冷凝段冷凝为液体释放热量,从而使冷凝段维持较高的温度,轴向均温性得到改善。从图8和图9可以看出,泡沫金属芯钠热管与无芯钠热管均具有较好的均温性能,且泡沫金属芯钠热管的均温性能略优于无芯钠热管。

-

本文研制了泡沫金属芯钠热管,实验考察和对比分析了加热温度对泡沫金属芯钠热管和无芯钠热管启动性能与均温性能的影响,结论如下:

(1)在加热温度为850℃时,泡沫金属芯钠热管成功启动,启动中出现冷凝段入口温度低于冷凝段中部的现象,说明管内部蒸汽流达到亚声速。

(2)当蒸发段加热温度过低时,钠热管无法完全启动,而完全启动时泡沫金属芯钠热管所需的加热温度低于无芯的。随着加热温度的增加,泡沫金属芯钠热管和无芯钠热管的启动时间缩短,在相同加热温度下泡沫金属芯钠热管的启动时间比无芯的短,泡沫金属芯钠热管在加热温度950℃时的启动时间约为39 min。

(3)无芯钠热管在蒸发段加热温度为850℃和900℃时的启动过程中出现了因气液携带导致的冷凝段冲管和温度骤变现象,而泡沫金属芯钠热管的启动过程较稳定。

(4)随着加热温度的增加,泡沫金属芯钠热管和无芯钠热管轴向均温性得到改善,且泡沫金属芯钠热管的均温性能略优于无芯的,最小轴向温差为265℃。

不同加热温度下泡沫金属芯钠热管启动性能试验研究

Experimental Study on Start-up Performance of Sodium Heat Pipe with Metal-Foam Wick at Different Heating Temperatures

-

摘要: 泡沫金属是一种具有良好传热性能的多孔材料,将泡沫金属作为吸液芯应用于热管中有望提高热管的工作性能。研制了泡沫金属芯钠热管,并实验研究和对比分析了泡沫金属芯钠热管与无芯钠热管在不同加热温度下的启动性能和均温性能。结果表明,泡沫金属芯钠热管完全启动时所需的加热温度低于无芯钠热管,且在相同加热温度下泡沫金属芯的启动时间较短;随着加热温度的增加,钠热管的启动时间缩短,轴向温度分布均匀性越好;泡沫金属芯钠热管的启动性能和均温性能均优于无芯钠热管。实验研究初步证明了采用泡沫金属作为高温热管吸液芯的优越性。Abstract: Metal foam is a kind of porous material with good heat transfer performance. The application of metal foam as a wick is expected to improve the heat transfer performance of heat pipes. A sodium heat pipe with a metal-foam wick was developed, and its start-up performance and isothermal performance were experimentally studied and compared to a wickless sodium heat pipe. The results show that the lowest heating temperature needed for successfully starting up a sodium heat pipe with a metal-foam wick is lower than that of a wickless sodium heat pipe. Also, the start-up time of the metal-foam wick sodium heat pipe is shorter than the wickless one at the same heating temperature. Meanwhile, the start-up time of the sodium heat pipe decreases with the increase in heating temperature, and the axial temperature distribution becomes more uniform. The start-up performance and isothermal performance of sodium heat pipe with metal-foam wick appeared to be better than the wickless one. The advantages of using a metal foam as a wick for high-temperature heat pipes are preliminarily proved by experimental research.

-

-

-

[1] Taner E. Design and production of high temperature heat pipe heat recovery units[J]. Journal of Molecular Structure,2020,1212:127927 doi: 10.1016/j.molstruc.2020.127927 [2] Zhang W,Zhang D,Liu X,et al. Thermal-hydraulic analysis of the thermoelectric space reactor power system with a potassium heat pipe radiator[J]. Annals of nuclear energy,2020,136(Feb.):107018 [3] Qu Wei,Wang Huanguang,Duan Yanjun. Startup characteristics and heat transfer limits of high and super high temperature heat pipes[J]. Journal of Engineering Thermophysics,2011,32(8):1345−1348 (曲伟,王焕光,段彦军. 高温及超高温热管的启动特性和传热极限[J]. 工程热物理学报,2011,32(8):1345−1348(in chinese) QU Wei, WANG Huanguang, DUAN Yanjun. Startup characteristics and heat transfer limits of high and super high temperature heat pipes[J]. Journal of Engineering Thermophysics, 2011, 32(8): 1345-1348 (in chinese) [4] Zhao Weilin,Zhuang Jun,Zhang Hong. Influences of the evaporator length and liquid-filled content on the startup operation of the high temperature sodium heat pipes[J]. Chemical Engineering & Machinery,2003,30(5):259−262 (赵蔚琳,庄骏,张红. 蒸发段长度与充液量对高温钠热管启动过程的影响[J]. 化工机械,2003,30(5):259−262(in chinese) doi: 10.3969/j.issn.0254-6094.2003.05.002 ZHAO Weilin, ZHUANG Jun, ZHANG Hong. Influences of the evaporator length and liquid-filled content on the startup operation of the high temperature sodium heat pipes[J]. Chemical Engineering & Machinery, 2003, 30(5): 259-262 (in chinese) doi: 10.3969/j.issn.0254-6094.2003.05.002 [5] Jia Xianjian,Guo Hang,Guo Qing,et al. Effect of heating temperature on start-up and heat transfer performance of na-k alloy heat pipe[J]. Acta Energiae Solaris Sinica,2019,40(1):17−23 (贾先剑,郭航,郭青,等. 加热温度对钠钾合金热管启动和传热性能影响[J]. 太阳能学报,2019,40(1):17−23(in chinese) JIA Xianjian, GUO Hang, GUO Qing, et al. Effect of heating temperature on start-up and heat transfer performance of na-k alloy heat pipe[J]. Acta Energiae Solaris Sinica, 2019, 40(1): 17-23 (in chinese) [6] Han Ye,Chai Baohua,Wei Guangren,et al. Test study for starting performance of high-temperature gravity potassium heat pipes with and without wick[J]. Atomic Energy Science and Technology,2019,53(1):38−44 (韩冶,柴宝华,卫光仁,等. 有芯和无芯高温重力钾热管启动性能试验研究[J]. 原子能科学技术,2019,53(1):38−44(in chinese) HAN Ye, CHAI Baohua, WEI Guangren, et al. Test study for starting performance of high-temperature gravity potassium heat pipes with and without wick[J]. Atomic Energy Science and Technology, 2019, 53(1): 38-44 (in chinese) [7] Ma Yugao,Zhang Yingnan,Yu Hongxing,et al. Evaporation and capillary characteristics of thin film on screen wick[J]. Atomic Energy Science and Technology,2022,56(6):1154−1162 (马誉高,张英楠,余红星,等. 丝网芯内钠薄液膜蒸发与毛细特性研究[J]. 原子能科学技术,2022,56(6):1154−1162(in chinese) doi: 10.7538/yzk.2021.youxian.0914 MA Yugao, ZHANG Yingnan, YU Hongxing, et al. Evaporation and capillary characteristics of thin film on screen wick[J]. Atomic Energy Science and Technology, 2022, 56(6): 1154-1162 (in chinese) doi: 10.7538/yzk.2021.youxian.0914 [8] Chen Yangyang,Pei Shengwang,Chen Xiaoguang,et al. Experimental investigation on heat transfer performance of pulsating heat pipeswith rectangular and circular channels[J]. Energy Conservation Technology,2019,37(4):291−295 (陈阳阳,裴圣旺,陈晓光,等. 矩形和圆形槽道脉动热管传热性能的实验研究[J]. 节能技术,2019,37(4):291−295(in chinese) doi: 10.3969/j.issn.1002-6339.2019.04.002 CHEN Yangyang, PEI Shengwang, CHEN Xiaoguang, et al. Experimental investigation on heat transfer performance of pulsating heat pipeswith rectangular and circular channels[J]. Energy Conservation Technology, 2019, 37(4): 291-295 (in chinese) doi: 10.3969/j.issn.1002-6339.2019.04.002 [9] Hoan T M, Toan N V, Hung N P, et al, Dependence of particle size and geometry of copper powder on the porosity and capillary performance of sintered porous copper wicks for heat pipes [J]. Metals, 2022, 12 (10): 1716 [10] Zhou J,Liu L,Yang X,et al. Visualization research on influencing factors of flat heat pipes[J]. Applied Thermal Engineering,2022,207:118193 doi: 10.1016/j.applthermaleng.2022.118193 [11] Ma Tingting,Zeng Jinling,Wang Xiaoyuan,et al. Experimental study on start-up characteristics of a high temperature special-shaped heat pipe[J]. Journal of Nanjing University of Technology,2017,39(3):6−10 (马婷婷,曾金令,王啸远,等. 高温异型热管启动性能实验研究[J]. 南京工业大学学报,2017,39(3):6−10(in chinese) MA Tingting, ZENG Jinling, WANG Xiaoyuan, et al. Experimental study on start-up characteristics of a high temperature special-shaped heat pipe[J]. Journal of Nanjing University of Technology, 2017, 39(3): 6-10 (in chinese) [12] Ding Li,Zhang Hong,Xu Hui,et al. Startup characteristics of high temperature heat pipe in solar power receiver[J]. Journal of Nanjing University of Technology,2009,31(5):79−85 (丁莉,张红,许辉,等. 太阳能接收器中高温热管启动性能[J]. 南京工业大学学报,2009,31(5):79−85(in chinese) DING Li, ZHANG Hong, XU Hui, et al. Startup characteristics of high temperature heat pipe in solar power receiver[J]. Journal of Nanjing University of Technology, 2009, 31(5): 79-85 (in chinese) [13] Wanison R,Kimura N,Murakami M,et al. Thermal performance of a cryogenic parallel heat pipe system[J]. Cryogenics,2022,128:103589 doi: 10.1016/j.cryogenics.2022.103589 [14] Bai Tong,Zhang Hong,Xu Hui,et al. Experimental study on heat transfer performance of a new type high temperature heat pipe with combined wick[J]. Thermal Power Generation,2013,42(5):59−63 (白穜,张红,许辉,等. 新型组合式吸液芯高温热管传热性能试验研究[J]. 热力发电,2013,42(5):59−63(in chinese) doi: 10.3969/j.issn.1002-3364.2013.05.059 BAI Tong, ZHANG Hong XU Hui, et al. Experimental study on heat transfer performance of a new type high temperature heat pipe with combined wick[J]. Thermal Power Generation, 2013, 42(5): 59-63 (in chinese) doi: 10.3969/j.issn.1002-3364.2013.05.059 [15] Xu Jiyuan,Zou Yong,Cheng Lin. Pore structure optimization and properties of composite wicks for loop heat pipes[J]. Proceedings of the CSEE,2012,32(23):70−74 (徐计元,邹勇,程林. 环路热管复合毛细芯的孔结构优化与性能研究[J]. 中国电机工程学报,2012,32(23):70−74(in chinese) doi: 10.13334/j.0258-8013.pcsee.2012.23.002 XU Jiyuan, ZOU Yong, CHENG Lin. Pore structure optimization and properties of composite wicks for loop heat pipes[J]. Proceedings of the CSEE, 2012, 32(23): 70-74 (in chinese) doi: 10.13334/j.0258-8013.pcsee.2012.23.002 [16] Zhang Shiwei. Foam metal research and application progress[J]. Powder Metallurgy Technology,2016,34(3):222−227 (张士卫. 泡沫金属的研究与应用进展[J]. 粉末冶金技术,2016,34(3):222−227(in chinese) doi: 10.3969/j.issn.1001-3784.2016.03.013 ZHANG Shiwei. Foam metal research and application progress[J]. Powder Metallurgy Technology, 2016, 34(3): 222-227 (in chinese) doi: 10.3969/j.issn.1001-3784.2016.03.013 [17] Fu Quanrong,Zhang Yifen,Duan Zihua,et al. Applications of porous foam metals in chemical equipment[J]. Chemical Engineering & Machinery,2010,37(6):805−810 (付全荣,张铱鈖,段滋华,等. 多孔泡沫金属及其在化工设备中的应用[J]. 化工机械,2010,37(6):805−810(in chinese) doi: 10.3969/j.issn.0254-6094.2010.06.037 FU Quanrong, ZHANG Yifen, DUAN Zihua, et al. Applications of porous foam metals in chemical equipment[J]. Chemical Engineering & Machinery, 2010, 37(6): 805-810 (in chinese) doi: 10.3969/j.issn.0254-6094.2010.06.037 [18] 施娟. 泡沫金属强化沸腾传热过程的研究[D]. 东南大学, 2015 SHI Juan. Study on boiling heat transfer enhancement with metal foams[D]. Southeast University, 2015 [19] Arik M,Bar-Cohen A,You S M. Enhancement of pool boiling critical heat flux in dielectric liquids by microporous coatings[J]. International Journal of Heat and Mass Transfer,2007,50(5):997−1009 [20] Jian Q A,Qin S B,Hai W A,et al. Performance characteristics of flat-plate oscillating heat pipe with porous metal-foam wicks[J]. International Journal of Heat and Mass Transfer,2019,137:20−30 doi: 10.1016/j.ijheatmasstransfer.2019.03.107 [21] Zheng Li,Li Juxiang,Zhu Min. Heat transfer of porous metal foam wick heat pipe[J]. CIESC Journal,2012,63(12):3861−3866 (郑丽,李菊香,朱珉. 泡沫金属吸液芯热管的传热性能[J]. 化工学报,2012,63(12):3861−3866(in chinese) doi: 10.3969/j.issn.0438-1157.2012.12.018 ZHENG Li, LI Juxiang, ZHU Min. Heat transfer of porous metal foam wick heat pipe[J]. CIESC Journal, 2012, 63(12): 3861-3866 (in chinese) doi: 10.3969/j.issn.0438-1157.2012.12.018 [22] Yao Shouguang,Cheng Qingfang,Wang Gongli,et al. Experimental investigation on heat transfer performance of foam metal wick heat pipe[J]. Journal of Jiangsu University of Science and Technology,2013,27(6):556−560 (姚寿广,程清芳,王公利,等. 以泡沫金属为吸液芯的纳米流体热管传热性能试验研究[J]. 江苏科技大学学报,2013,27(6):556−560(in chinese) YAO Shouguang, CHENG Qingfang, WANG Gongli, et al. Experimental investigation on heat transfer performance of foam metal wick heat pipe[J]. Journal of Jiangsu University of Science and Technology, 2013, 27(6): 556-560 (in chinese) [23] Zhao Weilin,Zhuang Jun,Zhang Hong. An analysis of vapor flow from the free molecular to continuum flow in the high temperature heat pipe[J]. Journal of University of Jinan,2004,18(2):176−178 (赵蔚琳,庄骏,张红. 高温热管内蒸汽从分子流动到连续流动过程分析[J]. 济南大学学报,2004,18(2):176−178(in chinese) ZHAO Weilin, ZHUANG Jun, ZHANG Hong. An analysis of vapor flow from the free molecular to continuum flow in the high temperature heat pipe[J]. Journal of University of Jinan, 2004, 18(2): 176-178 (in chinese) [24] Yu Ping,Zhang Hong,Xu Hui,et al. Startup performance of high-temperature sodium heat pipe with triangular groove wick[J]. Journal of Nanjing University of Technology,2015,37(1):99−103 (于萍,张红,许辉,等. 三角沟槽高温钠热管的启动性能[J]. 南京工业大学学报,2015,37(1):99−103(in chinese) YU Ping, ZHANG Hong, XU Hui, et al. Startup performance of high-temperature sodium heat pipe with triangular groove wick[J]. Journal of Nanjing University of Technology, 2015, 37(1): 99-103 (in chinese) [25] Chen Caifu,Qian Yihao,Luo Ying,et al. Experimental research on effect of inclination angle on carrying limit of gravity heat pipe[J]. Nuclear Power Engineering,2020,41(S2):21−26 (陈富财,钱益昊,罗英,等. 倾角对重力热管携带极限影响的实验研究[J]. 核动力工程,2020,41(S2):21−26(in chinese) doi: 10.13832/j.jnpe.2020.S2.0021 CHEN Caifu, QIAN Yihao, LUO Ying, et al. Experimental research on effect of inclination angle on carrying limit of gravity heat pipe[J]. Nuclear Power Engineering, 2020, 41(S2): 21-26 (in chinese) doi: 10.13832/j.jnpe.2020.S2.0021 -

首页

首页 登录

登录 注册

注册

下载:

下载: